3D NAND storage device and formation method thereof

A 3DNAND, memory technology, applied in semiconductor devices, electro-solid devices, electrical components and other directions, can solve the problem of easy fluctuation of gate spacer feature size and affecting memory performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

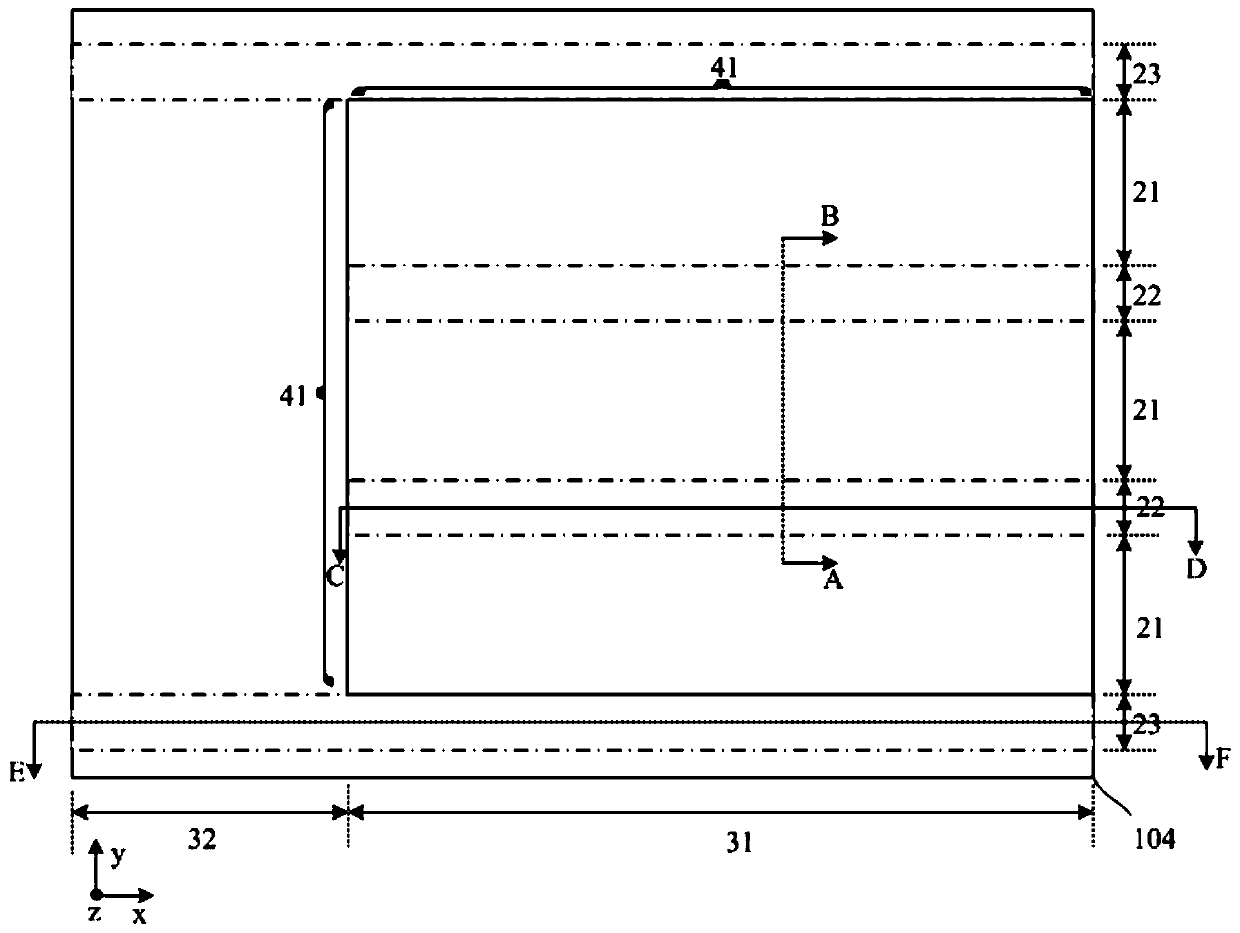

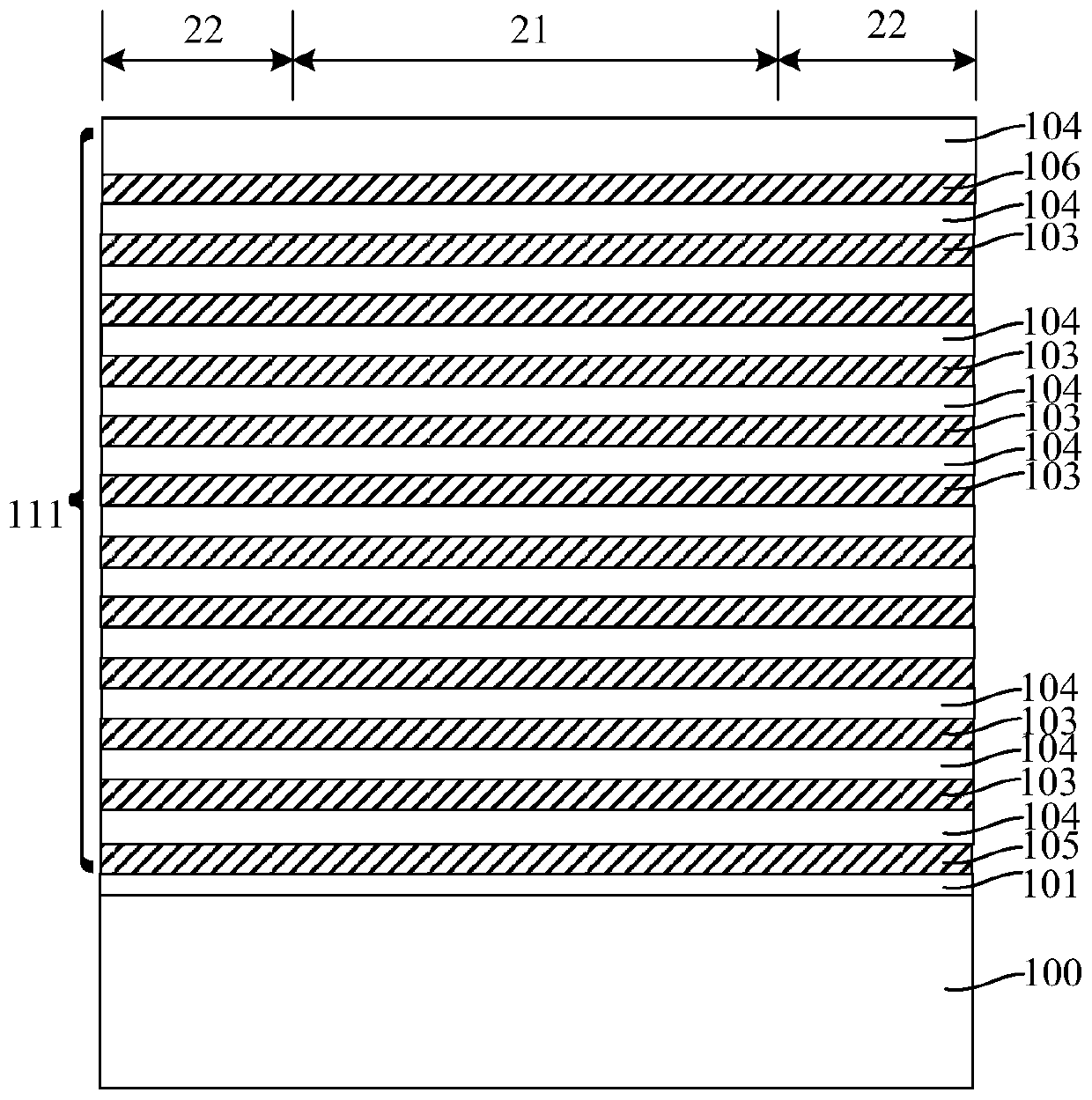

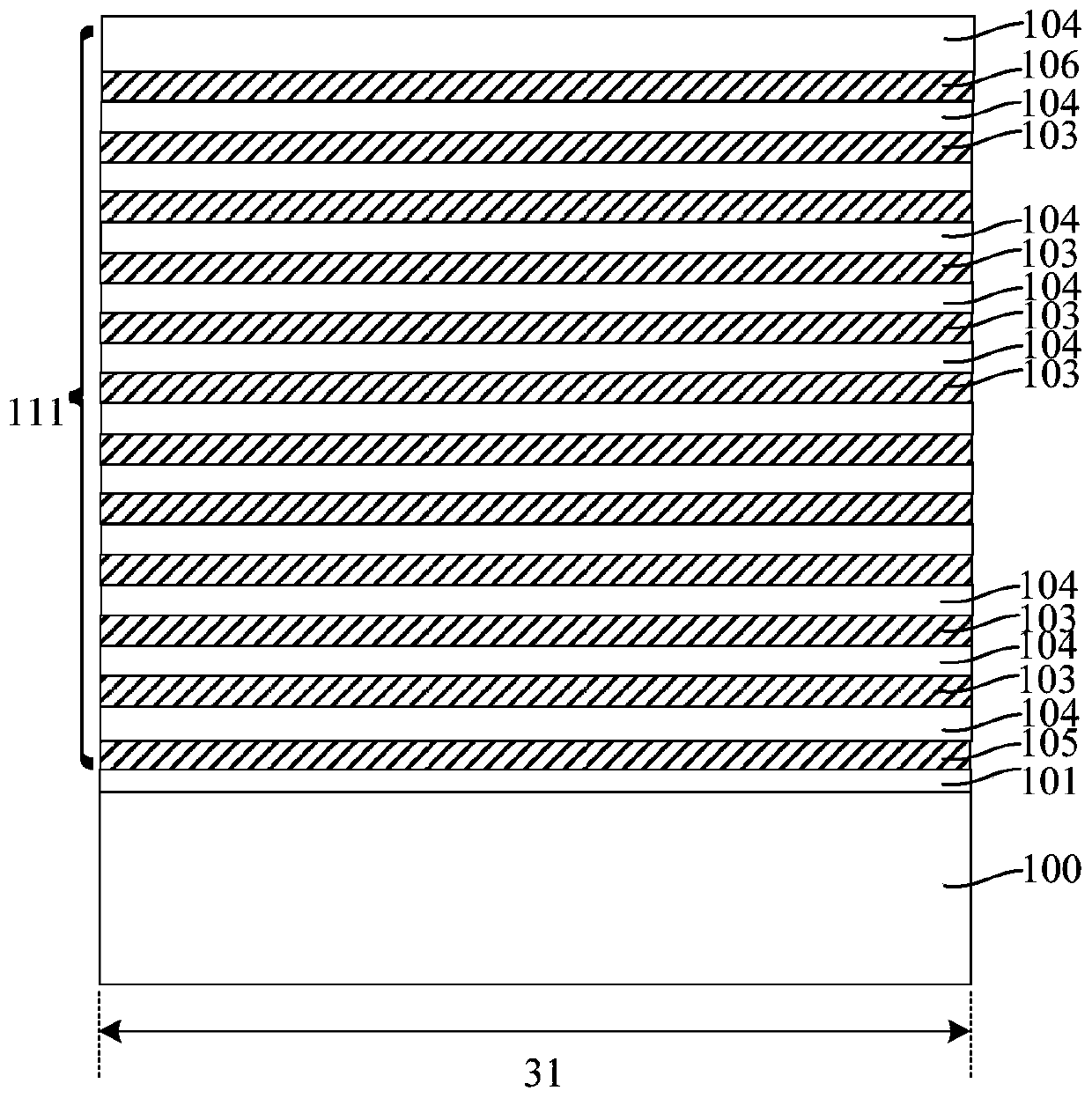

[0043] As mentioned in the background art, in the manufacturing process of the existing 3D NAND memory, the feature size of the gate spacers tends to fluctuate, which affects the performance of the memory.

[0044] It has been found through research that the side walls of the existing gate compartments are prone to inclination, so that the measured characteristic dimensions of the gate compartments tend to fluctuate.

[0045] Further studies have found that due to the large aspect ratio of the formed gate spacer, and after the formation of the gate spacer, the sacrificial layer in the stack structure will be removed, so that the strength of the stack structure is insufficient, which in turn makes the gate spacer The side walls of the groove are easily deformed or inclined. Moreover, since many manufacturing processes in the manufacturing process of 3D NAND memory are carried out at high temperature, the high temperature environment will cause deformation of the isolation layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com