Equipment management system

An equipment management and equipment technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as increasing work difficulty, labor, and reducing work efficiency, and achieve the goal of improving modern management levels, reducing equipment accidents, and reducing maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Example

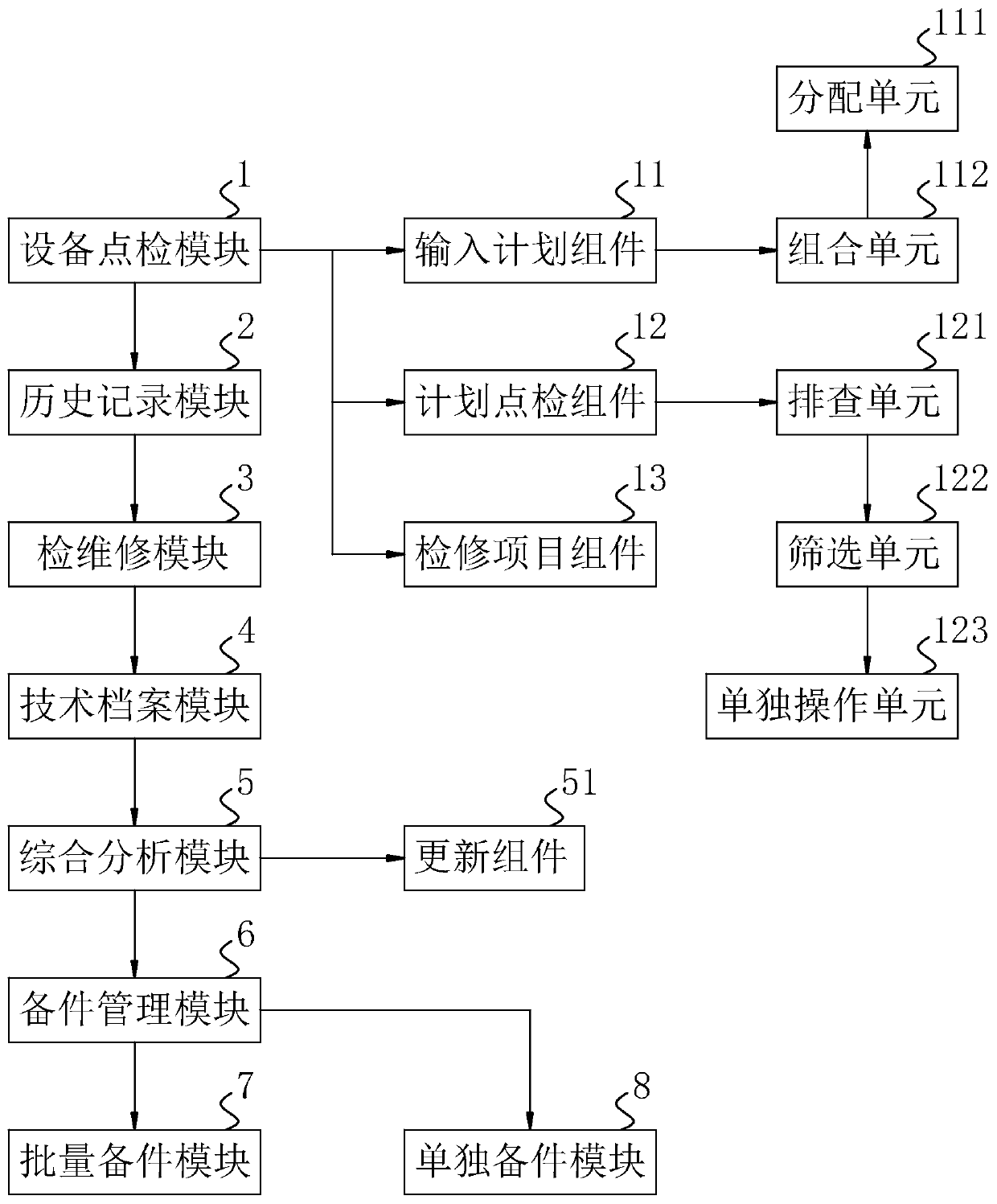

[0041] A device management system, such as figure 1 As shown, it includes the equipment check module 1, the history record module 2, the maintenance module 3, the technical file module 4, the spare parts management module 6 and the comprehensive analysis module 5. The above modules are all implemented by software to achieve their corresponding functions, and the system that runs the software uses VisualFoxpro6.0 database design tool software for development and design. VisualFoxpro6.0 is the most popular small-scale relational database system design tool in our country today. It is suitable for designing and developing various types of information management systems or maintaining databases. The information management system developed with VisualFoxpro 6.0 does not require high software and hardware configuration, and it is very cost-effective from an economic point of view. The bottom layer of the database adopts a basic data table structure, and button controls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com