Height-adjustable energy-saving type drying room

A drying room, adjustable technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of reduced color and quality of dried products, incomplete drying of products, high construction site requirements, etc., to achieve the goal of drying Short drying time, wide application range, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

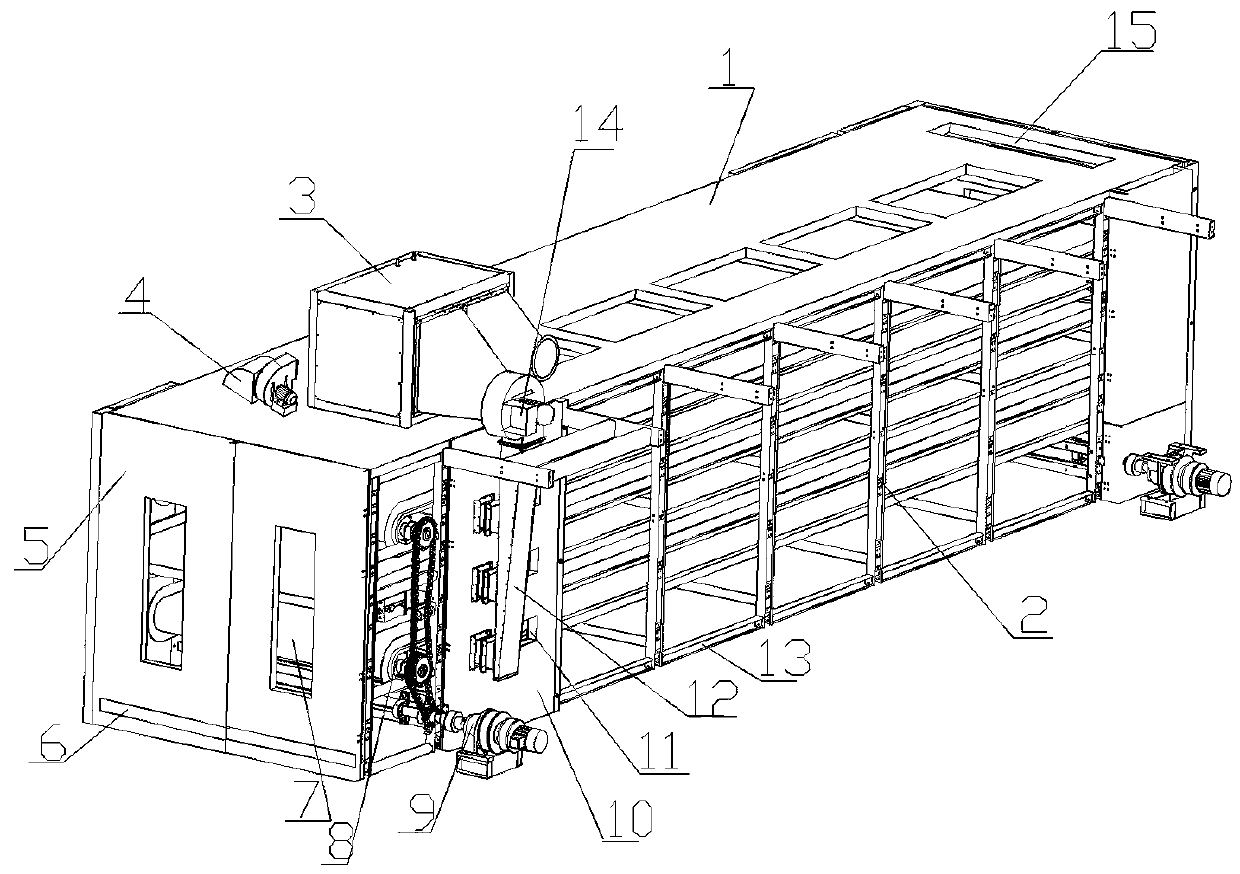

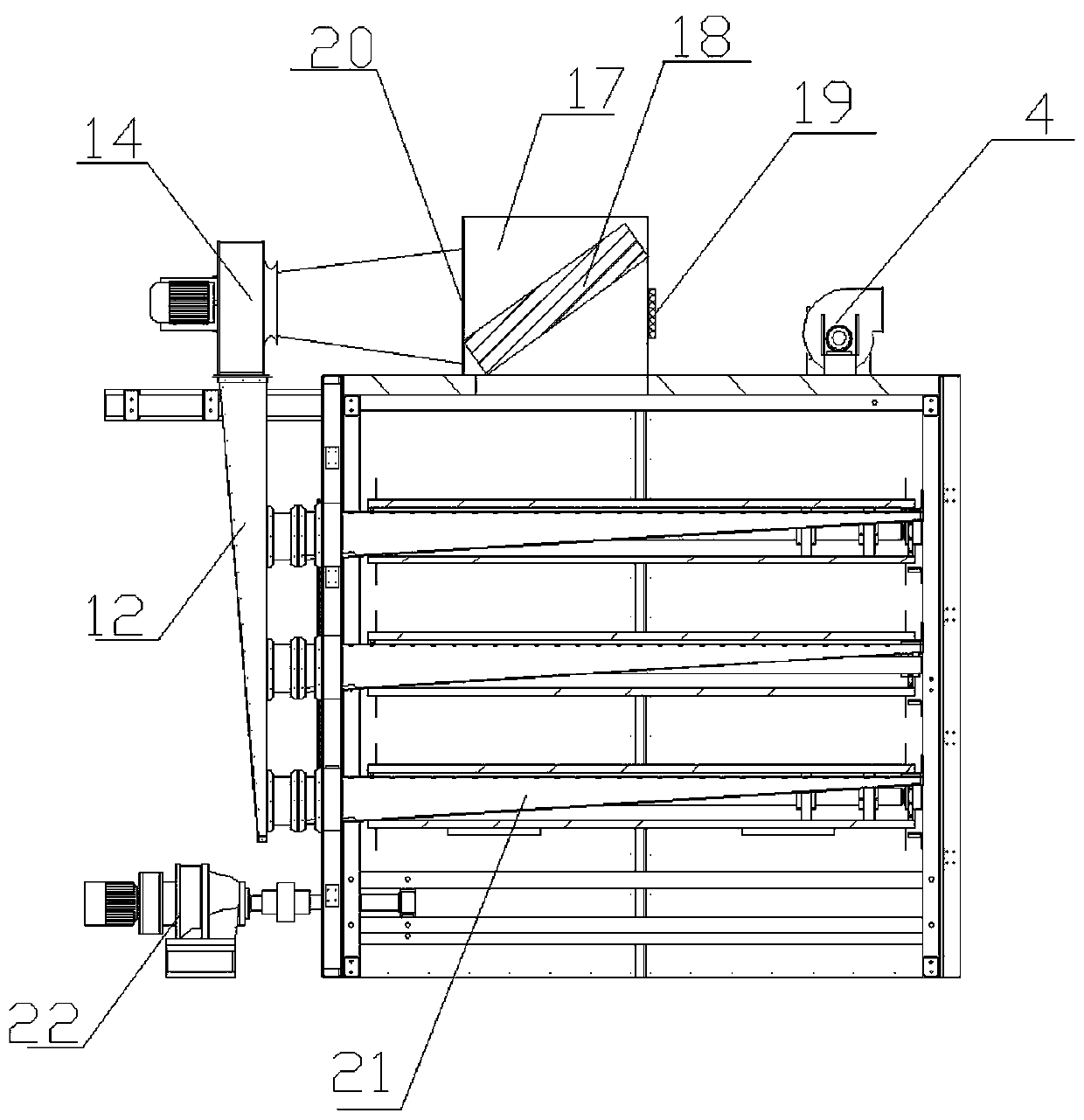

[0037] Such as Figure 1-12 As shown, a height-adjustable energy-saving drying room includes a drying room body 1, a conveying device arranged inside the drying room body 1, and a hot air drying system.

[0038] The drying room body 1 includes a drying frame 13 and an insulating layer arranged on the outside of the drying frame 13; the drying frame 13 includes at least one unit composed of cross braces 2, and each The sides of each unit are provided with insulation boards 10, and the insulation boards 10 are articulated with the drying frame 13 through connectors; The angle irons 36 are vertically arranged and connected together by pin shafts 37; the angle irons 36 are provided with mounting holes 38, one angle iron 36 is fixedly connected with the insulation board 10, and the other angle iron 36 is connected with the drying frame 13 fixed connections. Two ends of the drying frame 13 are respectively provided with a drying room door 5 ; an observation window 7 made of a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com