Automatic filament falling system of spinning winding machine

A winding machine and doffing technology, which is applied in the field of spinning production, can solve problems such as the difference in the weight of the silk spindle, the difference in the replacement time of the spindle, and the slow speed, so as to reduce the difference in weight, improve the efficiency of doffing, and reduce the labor intensity of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

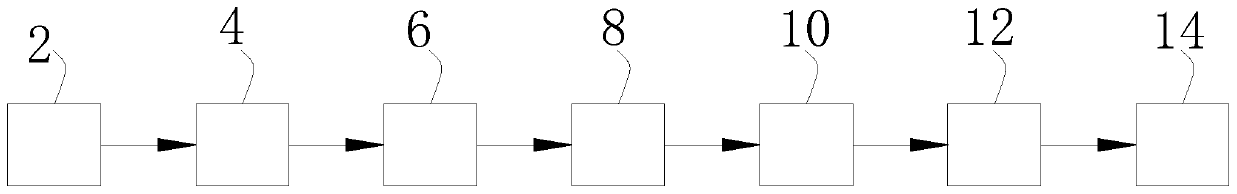

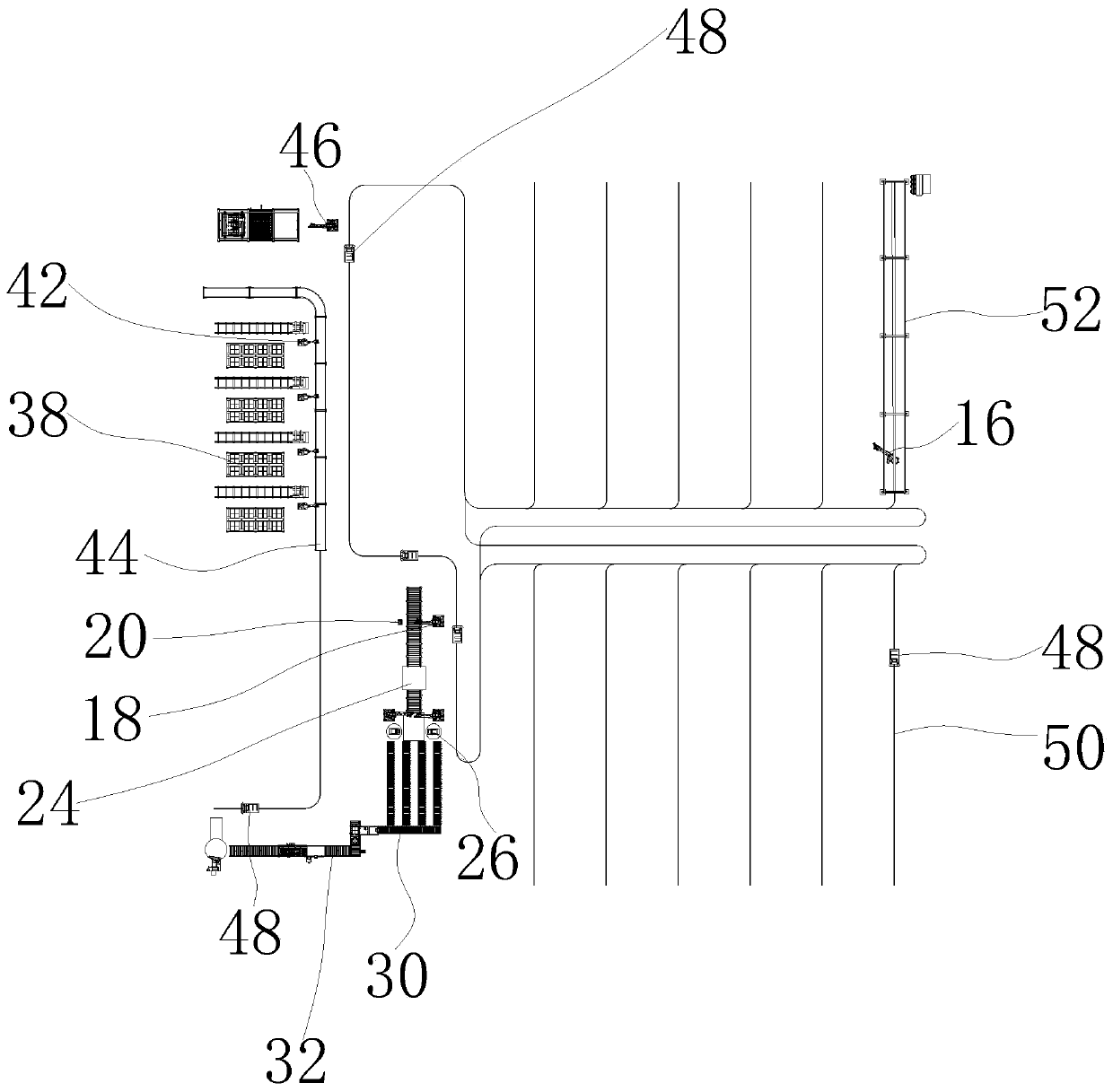

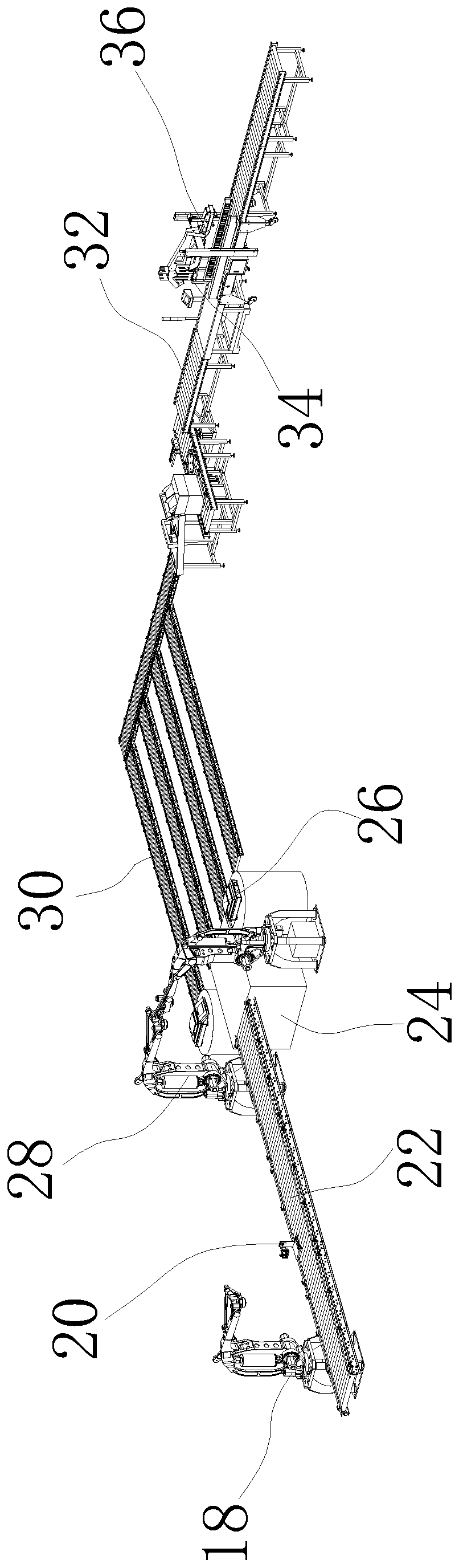

[0029] refer to Figure 1~4 As shown, this embodiment discloses an automatic doffing system for a spinning winding machine, including an empty spindle unpacking station 2, a doffing and bobbin changing station 4, a testing station 6, a spindle plastic sealing station 8, and a weighing and sorting station 10 , coding and packaging station 12, storage station 14 and AGV conveying system. The above-mentioned inspection station 6, spindle plastic sealing station 8, weighing and sorting station 10, and coding and packaging station 12 are arranged in sequence, and conveying lines for conveying materials are respectively arranged between adjacent two stations.

[0030] There are hundreds, thousands, or even tens of thousands of spinning winding machines in the spinning workshop. When the spinning winding machine is running, the silk thread is wound on the empty spindle. After a period of operation, the empty spindle becomes a certain amount of winding When the spindle is full of sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com