Turnover equipment for welding guide rail steel pedal and clamping locating method thereof

A technology for flipping equipment and pedals, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of trachea spatter and melting, safety, and reduce the quality of rail steel pedal products, so as to improve welding accuracy and finished products. quality, the effect of improving welding accuracy and welding quality, improving production efficiency and finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

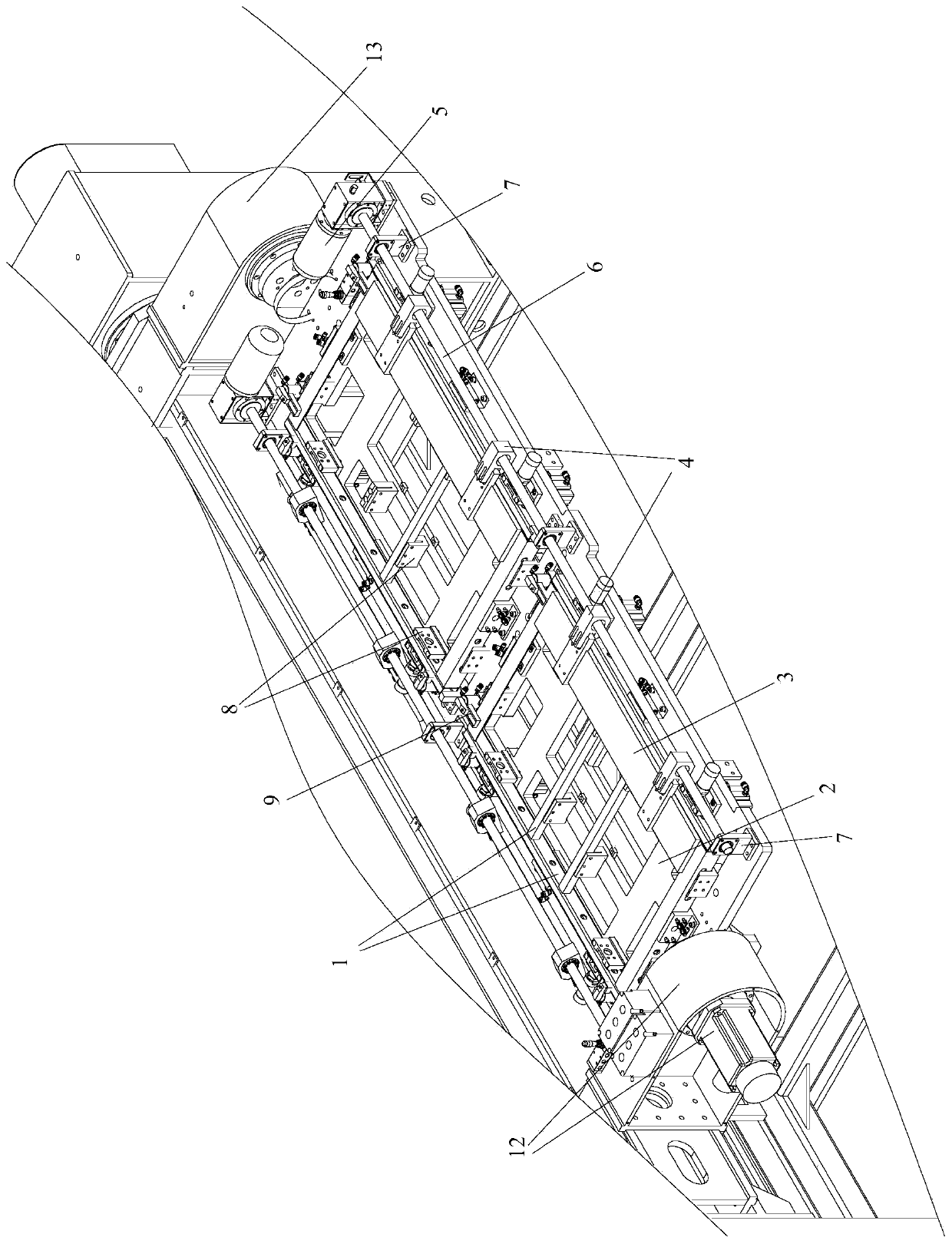

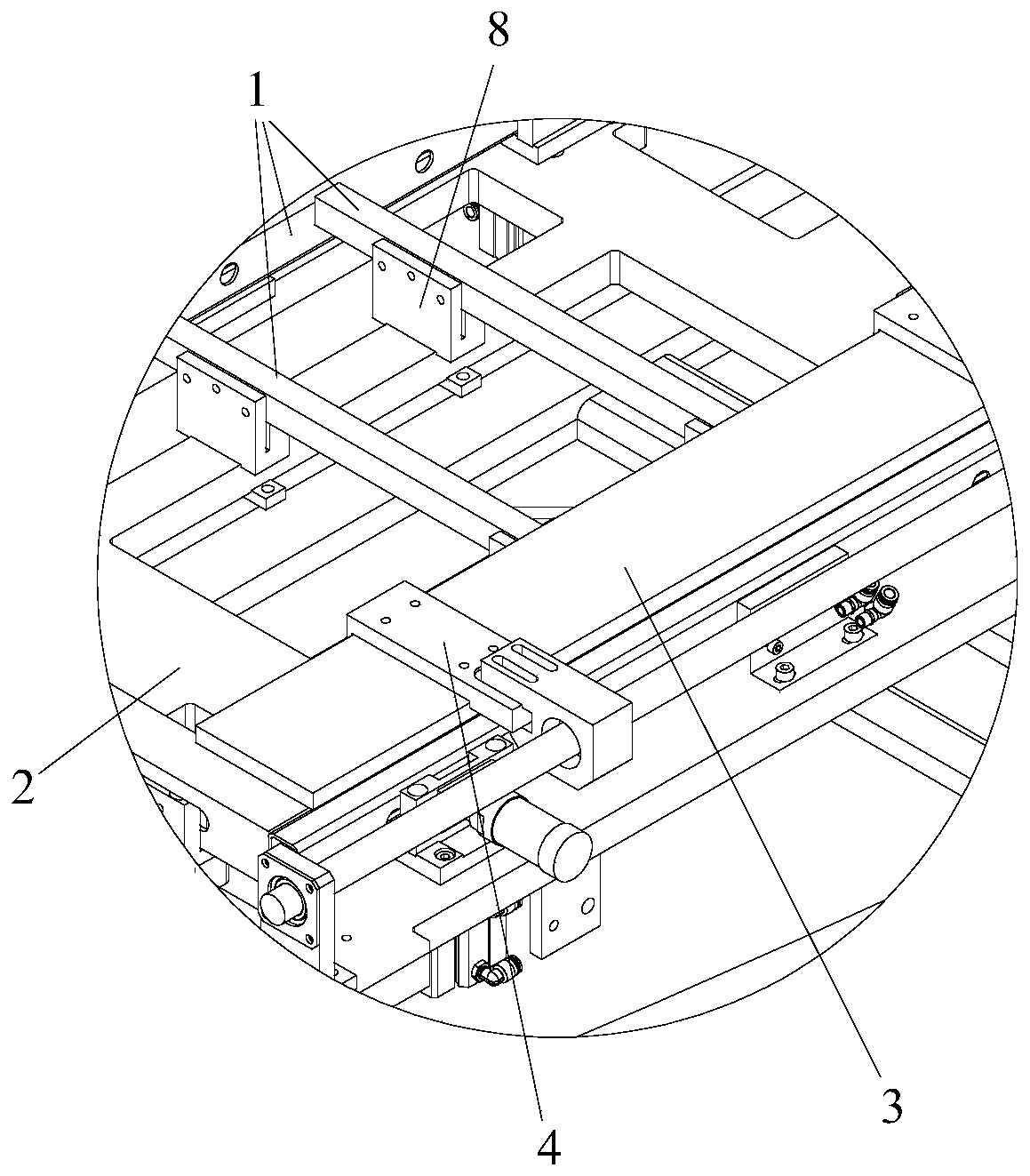

[0034] Such as Figure 1 to Figure 3 As shown, a kind of flipping equipment for rail steel pedal welding of the present invention comprises:

[0035] Working platform 2 for positioning the rail steel pedal and providing a welding platform;

[0036] The driving mechanism 12 and the driven rotating mechanism 13 for supporting the working platform 2 that are arranged on both sides of the working platform 2, the driving mechanism 12 includes a turning motor and is connected with the working platform 2 to realize the turning of the driving working platform 2; the driving mechanism 12 and The driven rotating mechanism 13 can be provided with a support placed on the ground to support the working platform 2, and the driving mechanism 12 and the driven rotating mechanism 13 can also be connected with an external supporting mechanism. Both the driving mechanism 12 and the driven rotating mechanism 13 are prior art, and are consistent with the structure in the existing overturning fixtu...

Embodiment 2

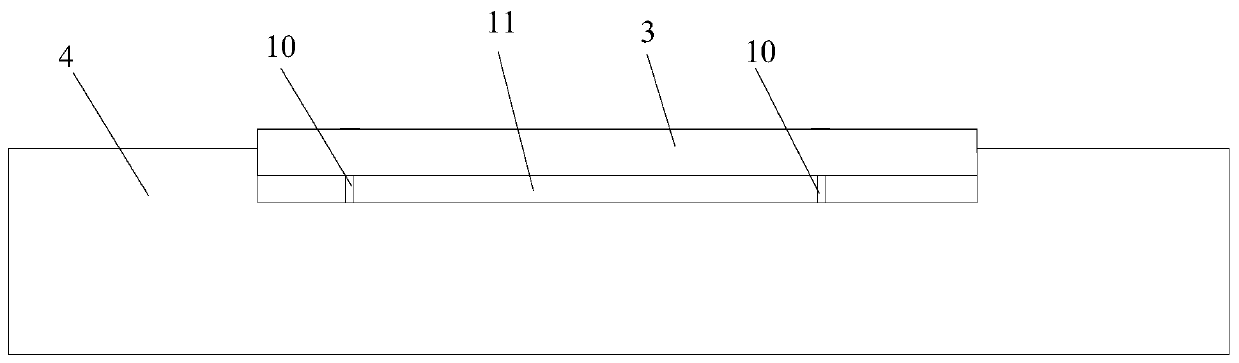

[0045] The only difference between this embodiment and the first embodiment is that there is an adjustment space between the pressure plate connector and the pressure plate, so that when the pressure plate is pressed against the panel of the guide rail steel pedal, the pressure plate can move in the adjustment space to adjust the alignment of the panel of the guide rail steel pedal. The pressing surface of the skeleton means that the connecting piece of the pressing plate is connected with the pressing plate by screws, and the distance between the head of the screw and the pressing plate is greater than the thickness of the connecting piece of the pressing plate, so that there is an adjustment space between the pressing plate and the connecting piece of the pressing plate, realizing When the pressing plate presses the panel of the steel pedal of the guide rail, the pressing plate can move in the adjustment space to adjust the pressing surface of the panel of the steel pedal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com