A laser coding method and device

A laser coding and type technology, applied in the field of tobacco coding, can solve the problems of incompetence, difficult identification, and large consumables, and achieve the effects of convenient identification, improved clarity, and improved coding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0040] According to the relevant regulations of the State Tobacco Monopoly Administration, when the cigarettes sold by tobacco companies at all levels leave the warehouse, each cigarette must be marked with a 32-digit code for anti-counterfeiting, anti-smuggling and information inquiry. In order to code cigarette rods, the present invention provides the following devices and methods.

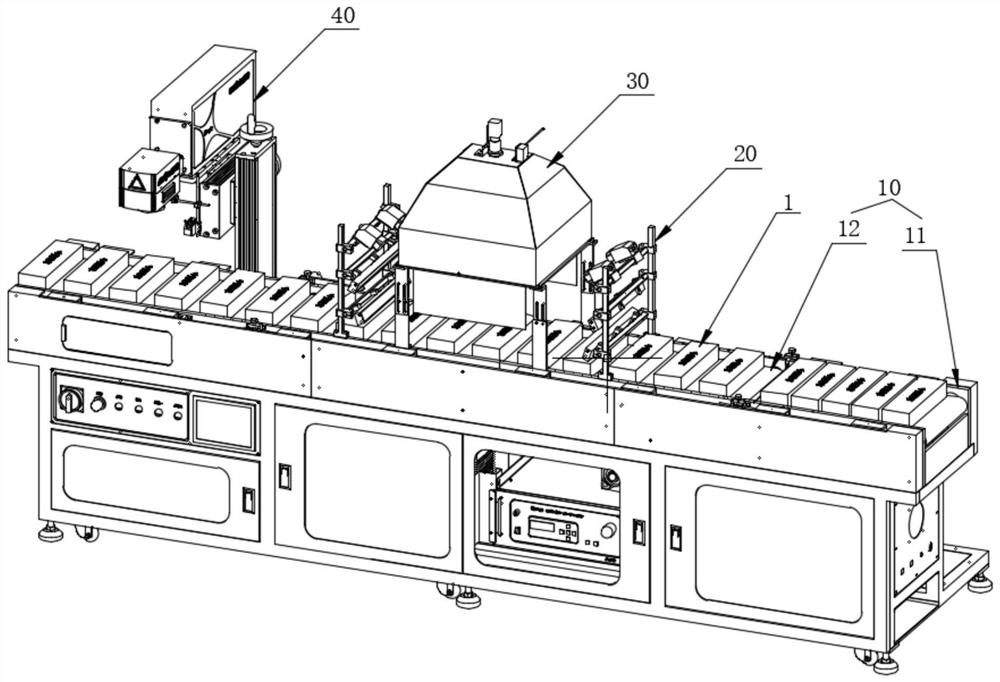

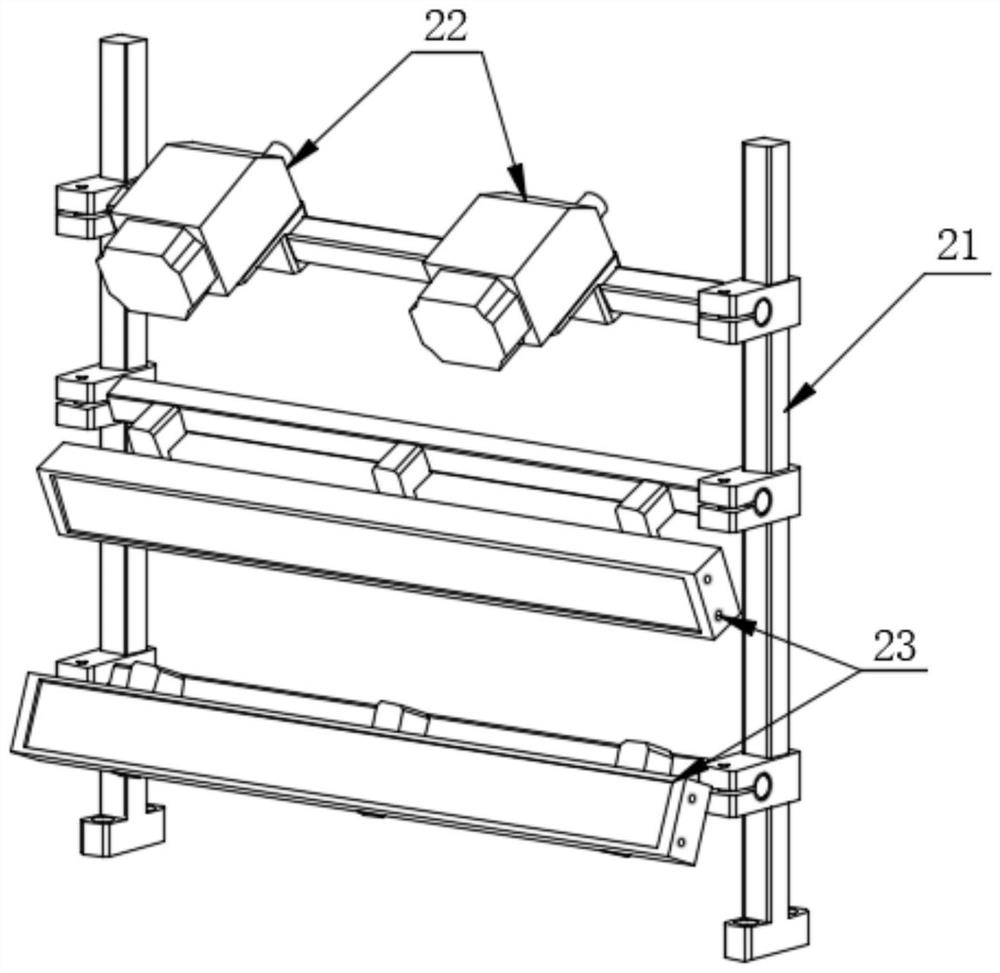

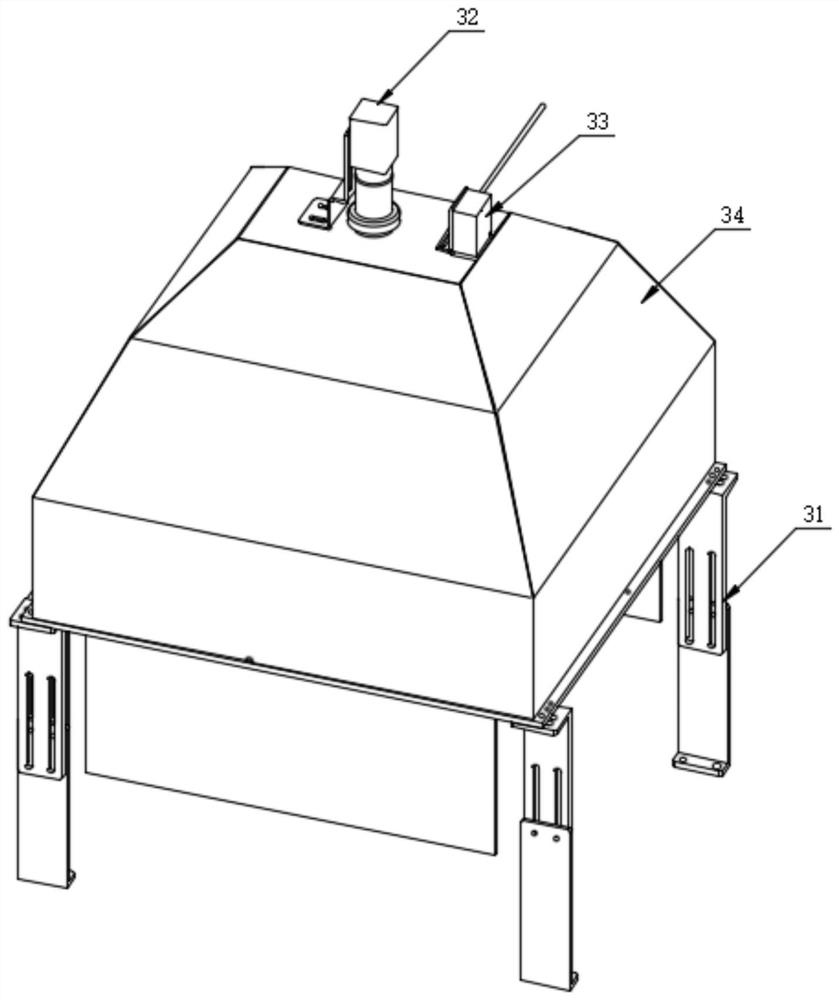

[0041] like figure 1 As shown, it is a laser coding device, including: a transportation line 10, a barcode collection mechanism 20, a camera recognition mechanism 30, a marking mechanism 40 and a control system, and the barcode collection mechanism 20, the camera recognition mechanism 30, and the marking mechanism 40 are spaced apart from each other. are arranged on the transportation line 10 and are respectively electrically connected to the control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com