Expansion connecting piece

A technology of expansion joints and joints, applied in the direction of joints, furniture joints, pins, etc., can solve the problems of complicated installation and large number of eccentric joint parts, and achieve the effect of easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

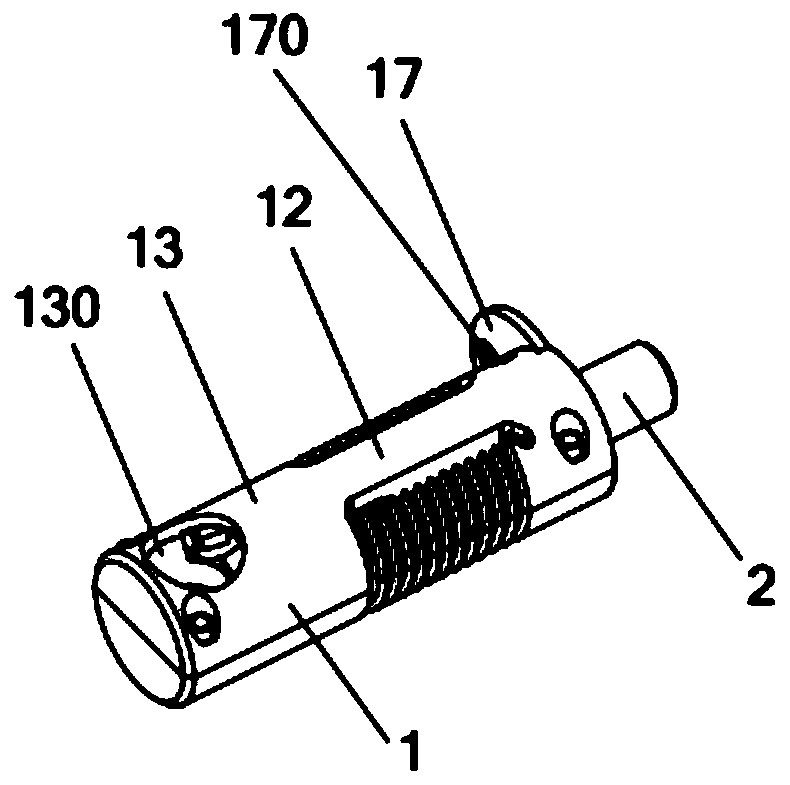

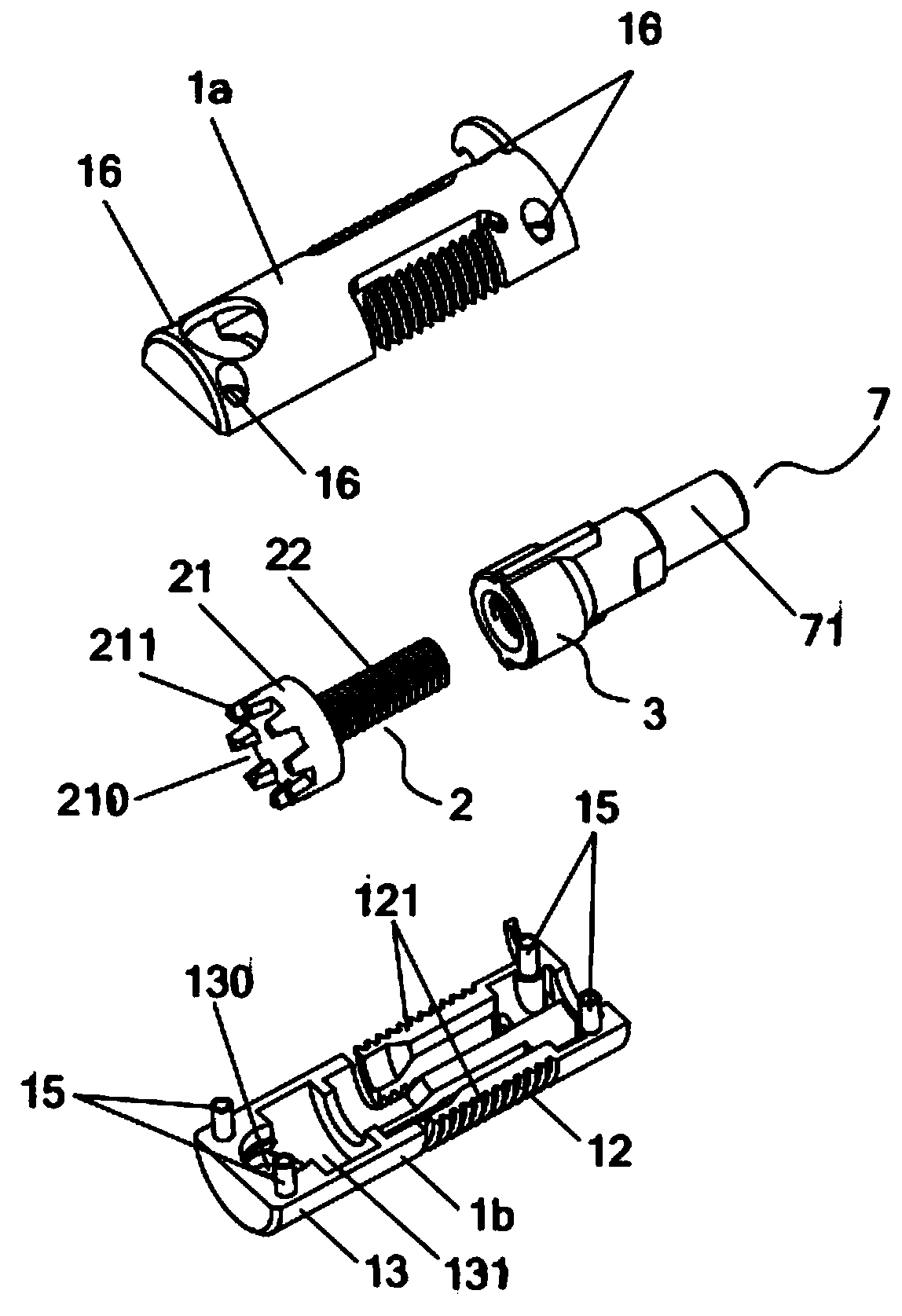

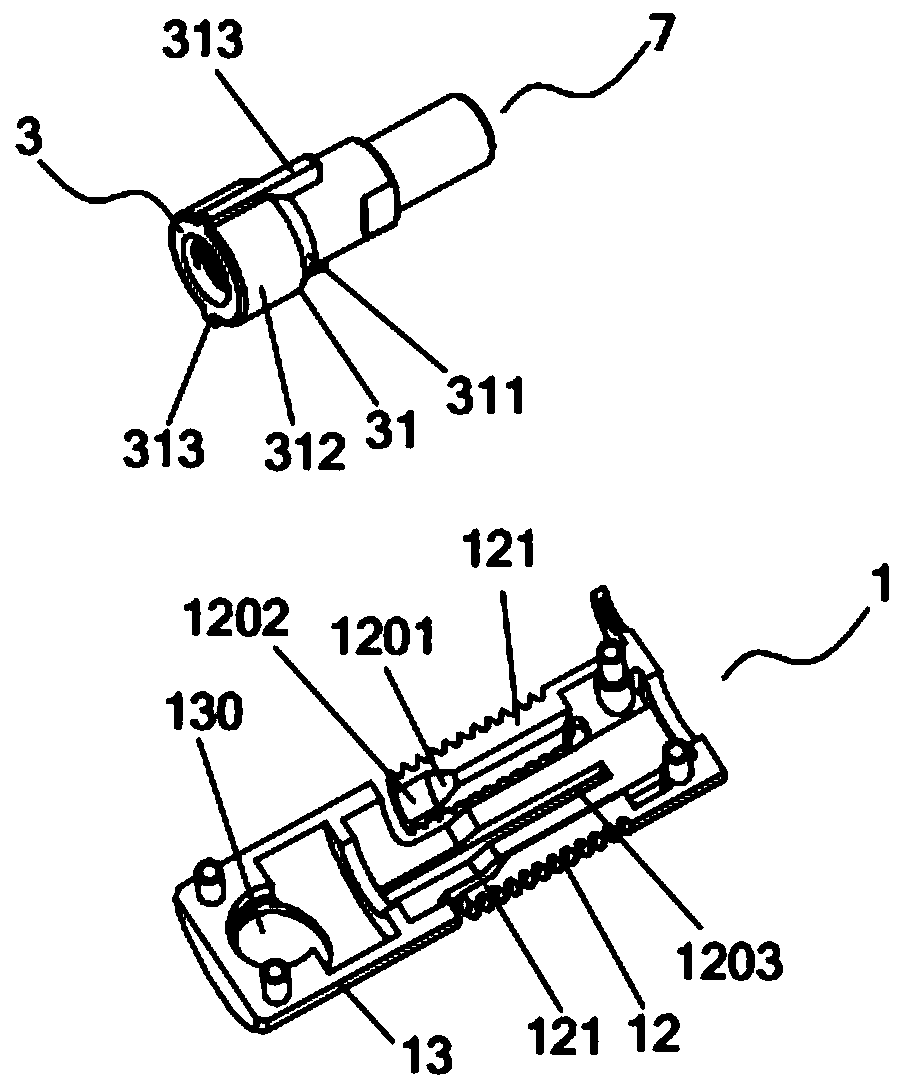

[0025] Embodiment one, with reference to Figure 1 to Figure 5 The expansion connector provided by the present invention includes a lifting screw 2, a side plate connector 7 and an expansion sleeve 1. The expansion sleeve 1 is a hollow cylindrical structure, and expansion parts 12 are sequentially arranged along the axial direction of the expansion sleeve 1. And the adjusting part 13, one end of the side plate connector 7 is provided with a connecting rod 71 for connecting with the side plate 01, the opposite end is provided with a nut 3, the lifting screw 2 includes a screw 22 and a head 21 connected to one end of the screw, The screw rod 22 is provided with an external thread, the nut 3 is provided with an internal thread that matches the external thread of the screw rod 22, the side plate connector 7 is threadedly connected with the screw rod 22 through the nut 3, the side plate connector 7 and the lifting screw 2 are arranged on the expansion Inside the casing 1, the nut 3...

Embodiment 2

[0040] Embodiment two, refer to Figure 6 to Figure 7The main structure, principle and function of the expansion connector provided in this embodiment are the same as those in Embodiment 1, and will not be repeated here. The difference is that it also includes embedded nuts 8, and the side plate connector 7 is used for The end of the connecting rod 71 connected with 01 is provided with a positioning connector 72, and the inside of the embedded nut 8 has a cavity 80 for accommodating the positioning connector, and the front end of the cavity 80 is provided with a front panel for clamping the positioning connector 81, the front panel 81 is provided with a positioning hole, the positioning hole is composed of a large hole 812 and a small hole 811, the large hole 812 can be used for the positioning connector 72 to pass through, and the diameter of the small hole 811 is the same as the outer diameter of the connecting rod 71 To adapt, during installation, the positioning connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com