Pipeline type rail logistics system

A track logistics and pipeline technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low efficiency, transportation efficiency is easily disturbed by external factors, etc., to save manpower and material resources, reduce energy consumption, Effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

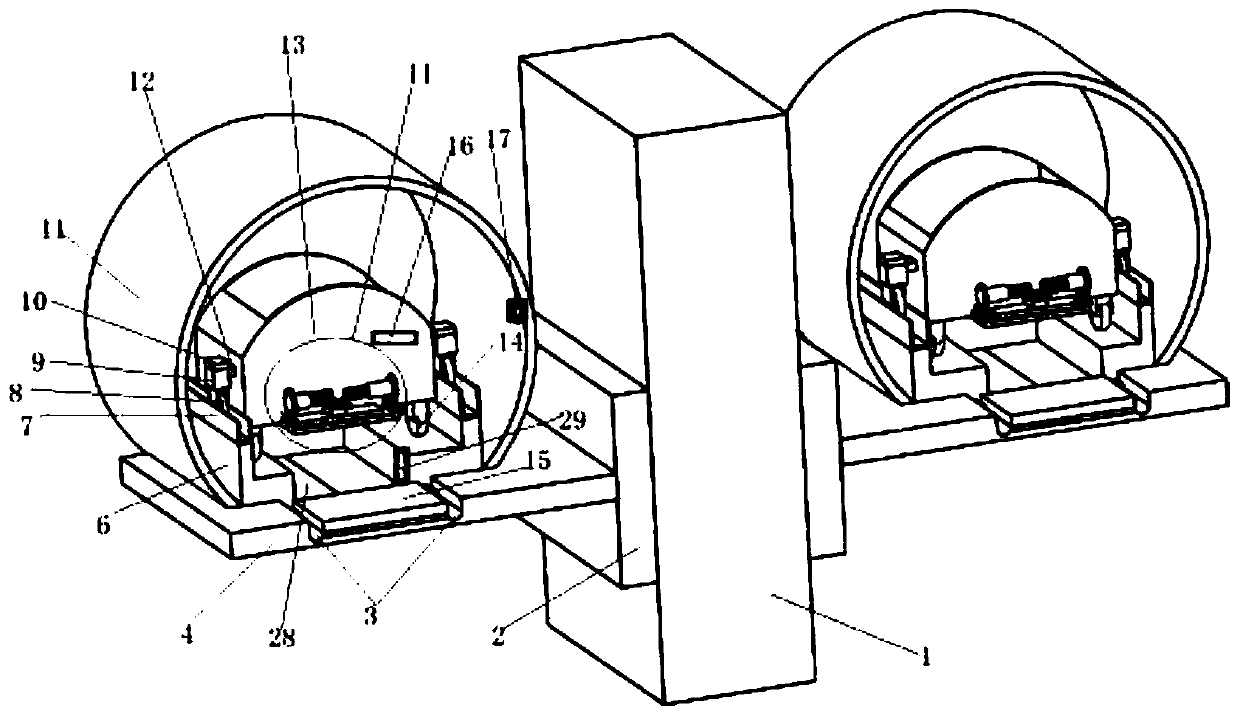

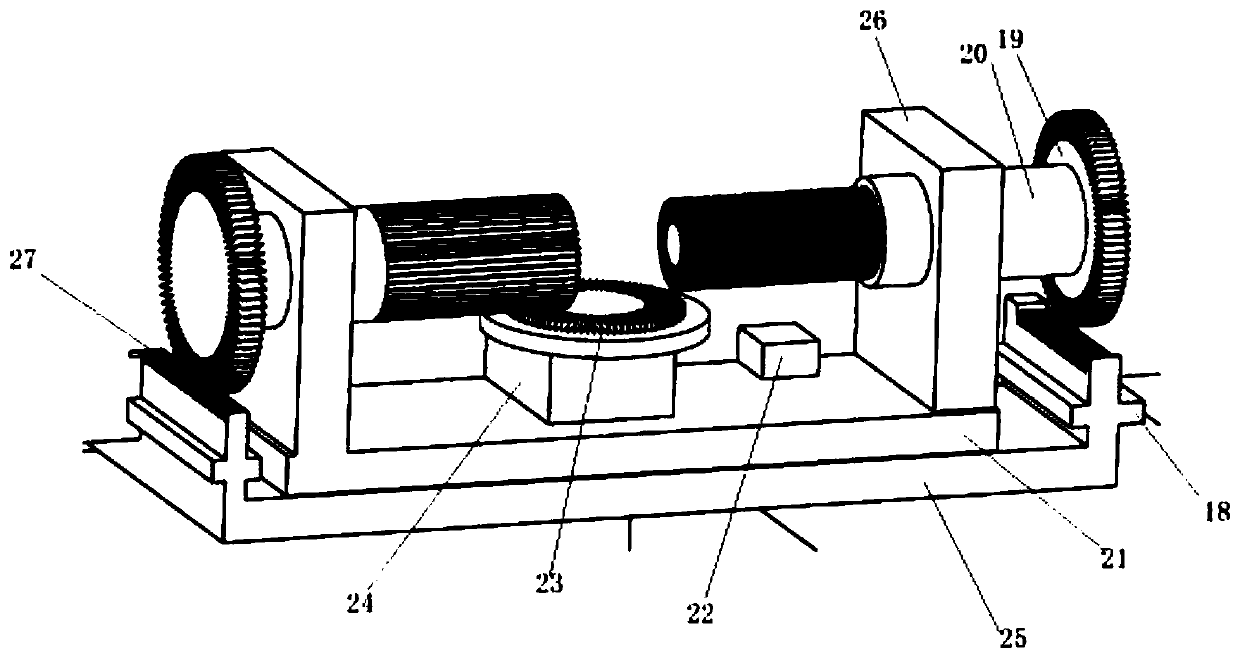

[0018] Such as Figure 1-2 As shown, a pipeline track logistics system includes a base frame 1, a fixing piece 2, a placement slot 3, a fixing table 4, a track 6, a guide rail 7, a guide wheel 8, a connecting piece 9, a wireless remote receiver 10, and a guide arm 12. Pipeline 11, logistics vehicle 13, power wheel 14, power storage device 15, coding area 16, scanner 17, movable block 18, gear 19, connecting shaft 20, steering wheel 23, first motor 24, first sensor 22. Driver 21, logistics warehouse door 25, support frame 26, rack 27, unloading door 28, second sensor 29, the base frame 1 is provided with a fixed platform 4, and the fixed platform 4 and the base frame 1 pass through The fixture 2 is fixedly connected, the fixed table 4 is provided with a pipeline 11, the pipeline 11 is provided with a scanner 17, the pipeline 11 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com