Clamping device for electronic element welding

A technology for clamping devices and electronic components, applied in auxiliary devices, welding equipment, metal processing equipment, etc., can solve problems such as danger, injury, and inaccurate welding, and achieve the effect of high safety and avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

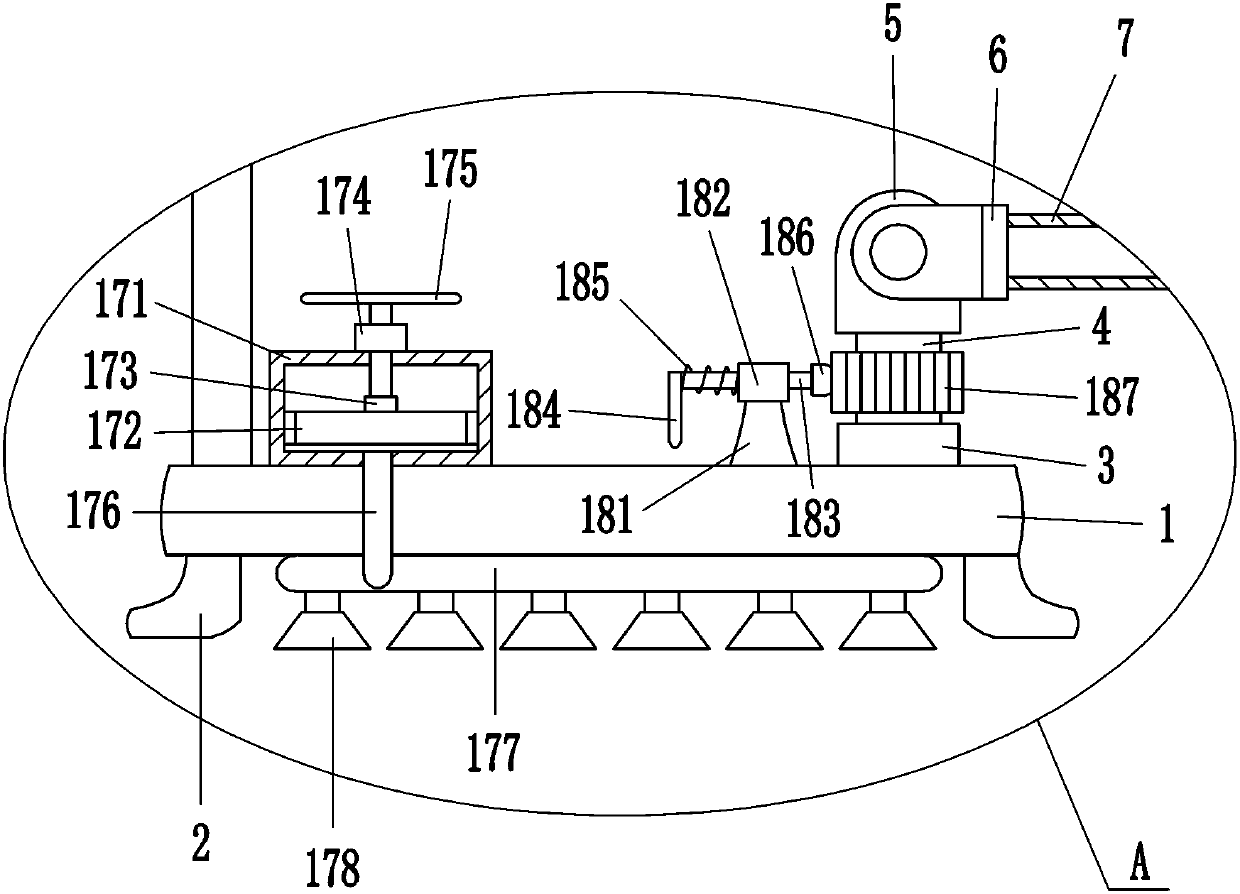

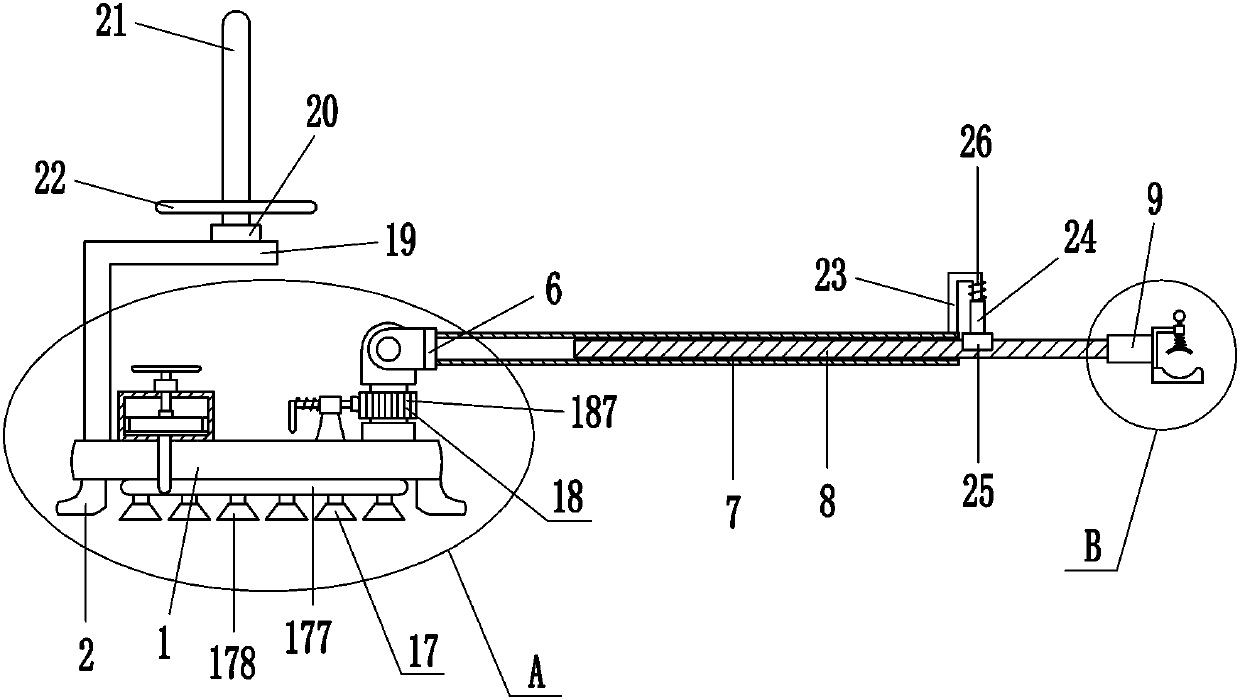

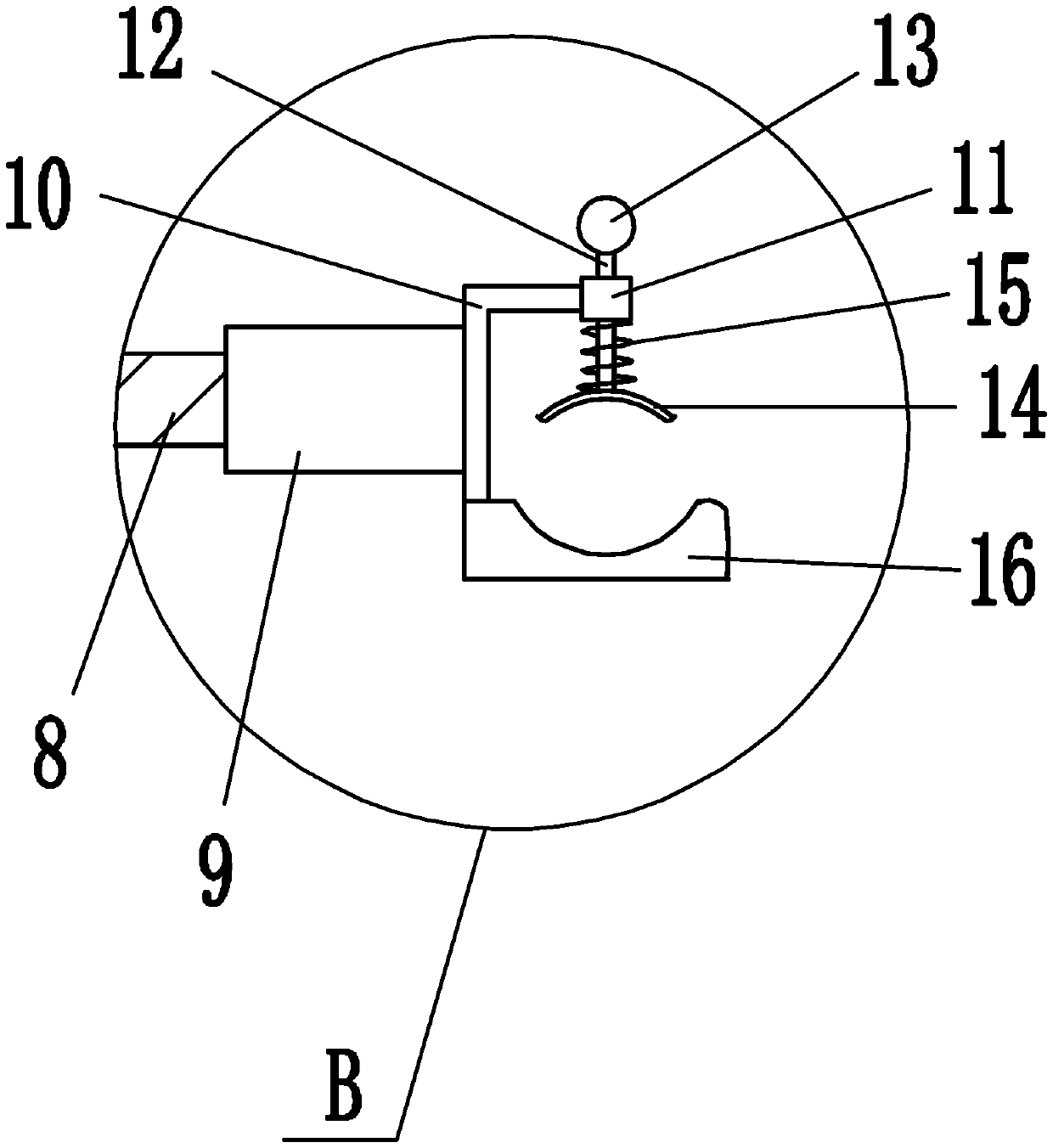

[0021] A clamping device for electronic component welding, such as Figure 1-3 As shown, it includes a base 1, a leg 2, a first bearing seat 3, a rotating shaft 4, a hinge seat 5, a connecting block 6, a hollow sleeve 7, a connecting rod 8, a damping sleeve 9, a 7-shaped plate 10, and a sliding sleeve 11. Slide bar 12, pull block 13, arc-shaped clamping plate 14, first spring 15 and card seat 16, two outriggers 2 are connected to the left and right sides of the bottom of the base 1, and the first bearing is installed on the right side of the top of the base 1 Seat 3, the first bearing seat 3 is connected with a rotating shaft 4, the top of the rotating shaft 4 is equipped with a hinged seat 5, the hinged seat 5 is rotatably connected with a connecting block 6, the right side of the connecting block 6 is connected with a hollow sleeve 7, and the hollow sleeve 7 is provided with a connecting rod 8, the right part of the connecting rod 8 is equipped with a damping sleeve 9, the r...

Embodiment 2

[0023] A clamping device for electronic component welding, such as Figure 1-3 As shown, it includes a base 1, a leg 2, a first bearing seat 3, a rotating shaft 4, a hinge seat 5, a connecting block 6, a hollow sleeve 7, a connecting rod 8, a damping sleeve 9, a 7-shaped plate 10, and a sliding sleeve 11. Slide bar 12, pull block 13, arc-shaped clamping plate 14, first spring 15 and card seat 16, two outriggers 2 are connected to the left and right sides of the bottom of the base 1, and the first bearing is installed on the right side of the top of the base 1 Seat 3, the first bearing seat 3 is connected with a rotating shaft 4, the top of the rotating shaft 4 is equipped with a hinged seat 5, the hinged seat 5 is rotatably connected with a connecting block 6, the right side of the connecting block 6 is connected with a hollow sleeve 7, and the hollow sleeve 7 is provided with a connecting rod 8, the right part of the connecting rod 8 is equipped with a damping sleeve 9, the r...

Embodiment 3

[0026] A clamping device for electronic component welding, such as Figure 1-3 As shown, it includes a base 1, a leg 2, a first bearing seat 3, a rotating shaft 4, a hinge seat 5, a connecting block 6, a hollow sleeve 7, a connecting rod 8, a damping sleeve 9, a 7-shaped plate 10, and a sliding sleeve 11. Slide bar 12, pull block 13, arc-shaped clamping plate 14, first spring 15 and card seat 16, two outriggers 2 are connected to the left and right sides of the bottom of the base 1, and the first bearing is installed on the right side of the top of the base 1 Seat 3, the first bearing seat 3 is connected with a rotating shaft 4, the top of the rotating shaft 4 is equipped with a hinged seat 5, the hinged seat 5 is rotatably connected with a connecting block 6, the right side of the connecting block 6 is connected with a hollow sleeve 7, and the hollow sleeve 7 is provided with a connecting rod 8, the right part of the connecting rod 8 is equipped with a damping sleeve 9, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com