Material transportation truck axle gear box II

A technology for axle gearboxes and transport vehicles, which is applied to gear transmissions, belts/chains/gears, components with teeth, etc., can solve the problems of technology being restricted by people and high cost, and achieve compact space structure, light weight and low manufacturing cost. and cycle-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

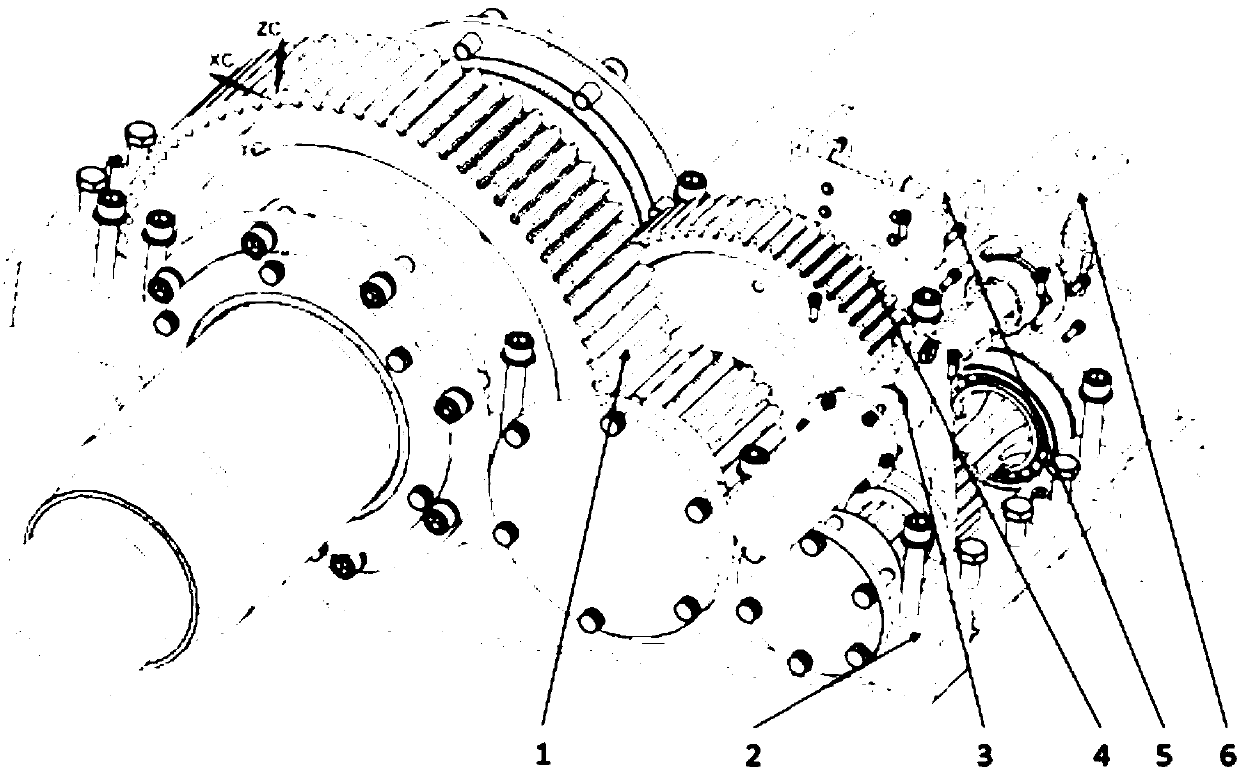

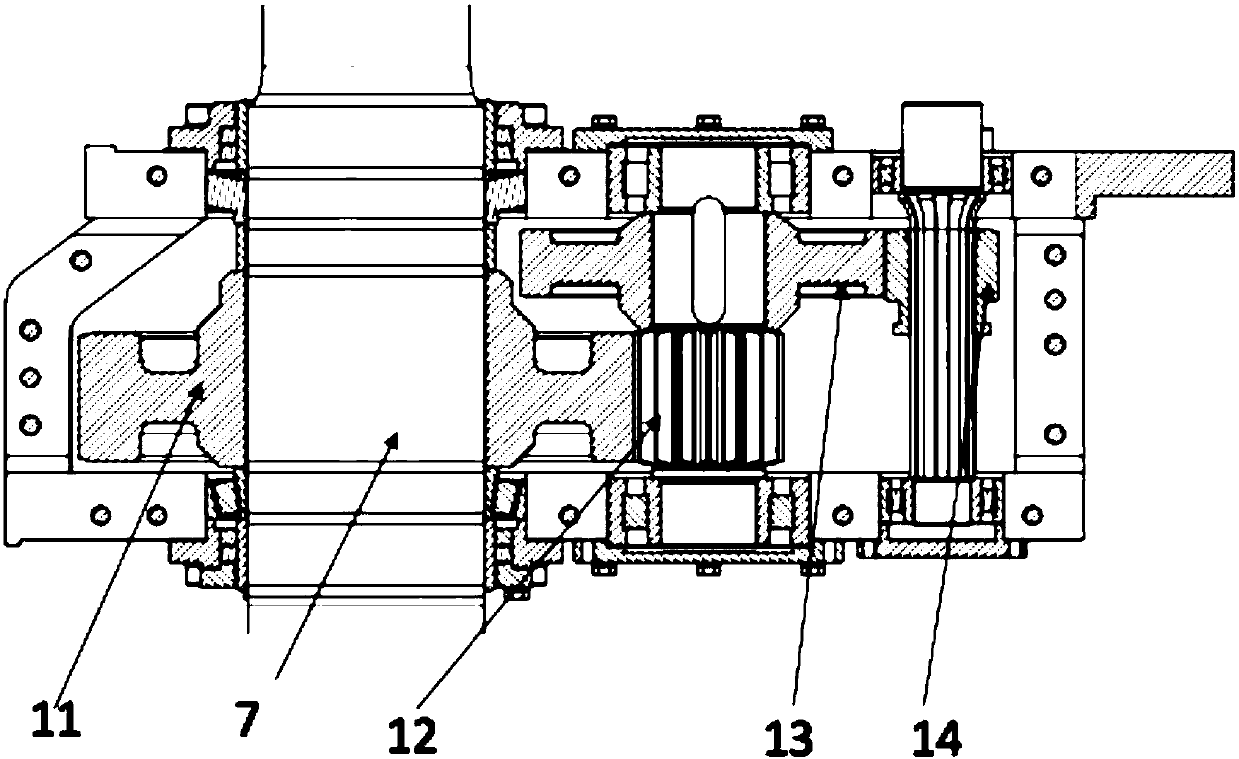

[0037] Embodiment 1.1: A material transport vehicle axle gearbox, which includes a box body, and the box body includes a first-stage reduction mechanism composed of two mutually meshing gears I and gear II, and the gear I is sleeved on the running wheel of the material transport vehicle On the axle, the gear II is installed on the intermediate shaft, and the gear III is also set on the intermediate shaft. The gear III meshes with the gear IV. The gear IV is set on the input shaft. The gear III constitutes a two-stage reduction mechanism. Said gear IV is a shift gear, and the gear IV is connected to a shift mechanism, and the end of the shift mechanism includes a gear locking device; the gear speed ratio distribution is: Z I =71, tooth width 115mm; Z II =16, tooth width 119mm; Z III =65, tooth width 60mm; Z IV =18, tooth width 66mm.

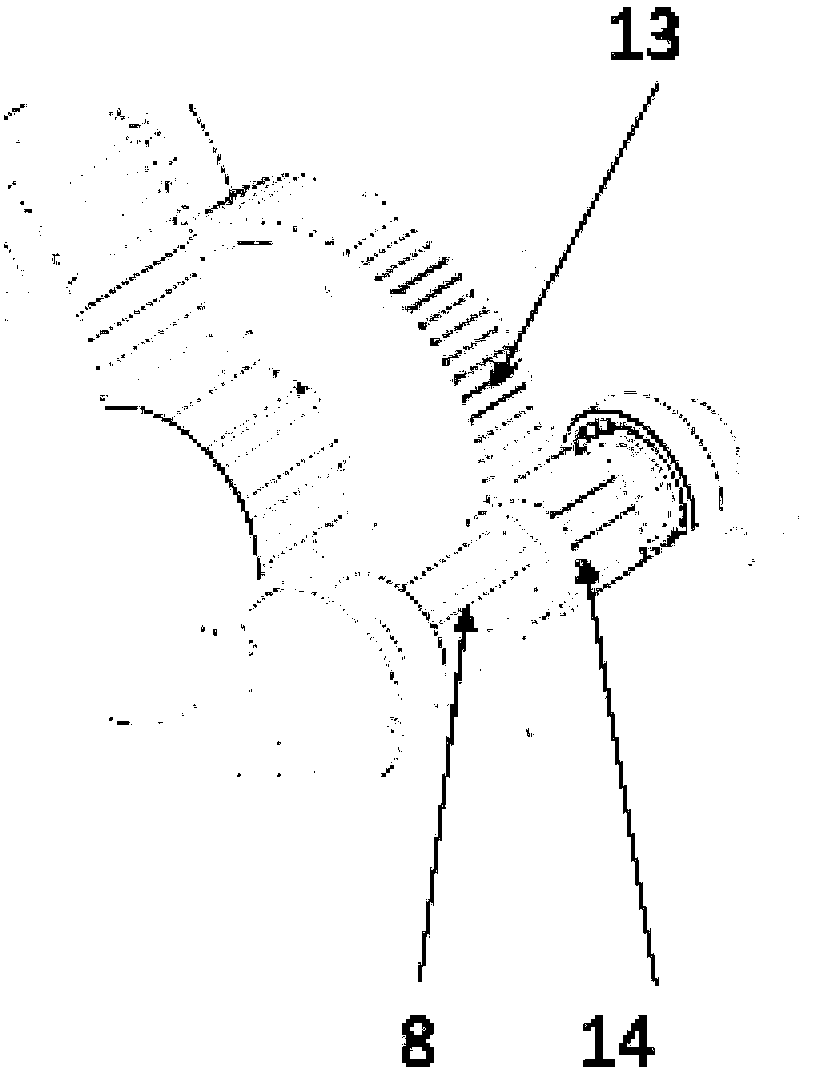

[0038] The gear position locking device includes the lower part of the shift fork connected to one end of the gear IV. The upper part of the s...

Embodiment 12

[0043] Embodiment 1.2: a kind of operation method of axle gear box of material transportation vehicle: it comprises

[0044] a. When the system pressure is zero, the shift mechanism of the axle gearbox is always in the disengagement position through the elastic force of the return spring;

[0045] b. When the control system initiates the shifting action, the large chamber of the shift oil cylinder will enter the oil, push the piston rod out, and drive the shifting gear on the fork (that is, gear IV) to mesh with the gear III on the intermediate shaft to carry out shifting;

[0046] c. After the shifting is completed, the large chamber of the shifting oil cylinder maintains pressure to maintain the shifting state.

[0047] d. When the control system initiates a disengagement action, oil enters the small chamber of the shift oil cylinder, pushes the piston rod to retract, and drives the shifting gear (that is, gear IV) on the fork to disengage from the gear III on the intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Tooth width | aaaaa | aaaaa |

| Tooth width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com