A perforating device for well completion

A technology of passing through holes and hoses, which is applied in wellbore/well components, production fluid, earthwork drilling and mining, etc. It can solve the problems of limited jet rock breaking effect and insufficient communication range of channels, etc., and achieves small space occupation and simple structure Effect of compactness and lengthening hole depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

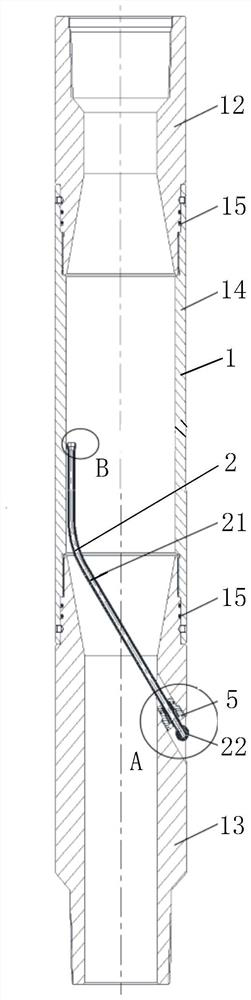

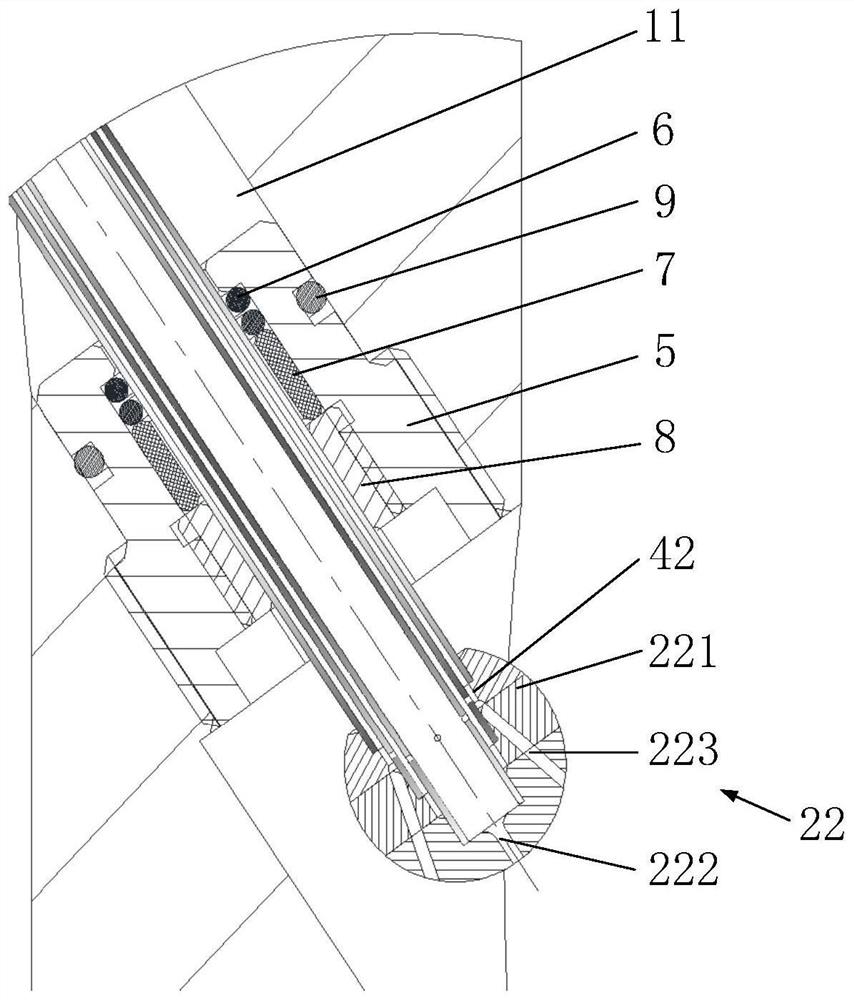

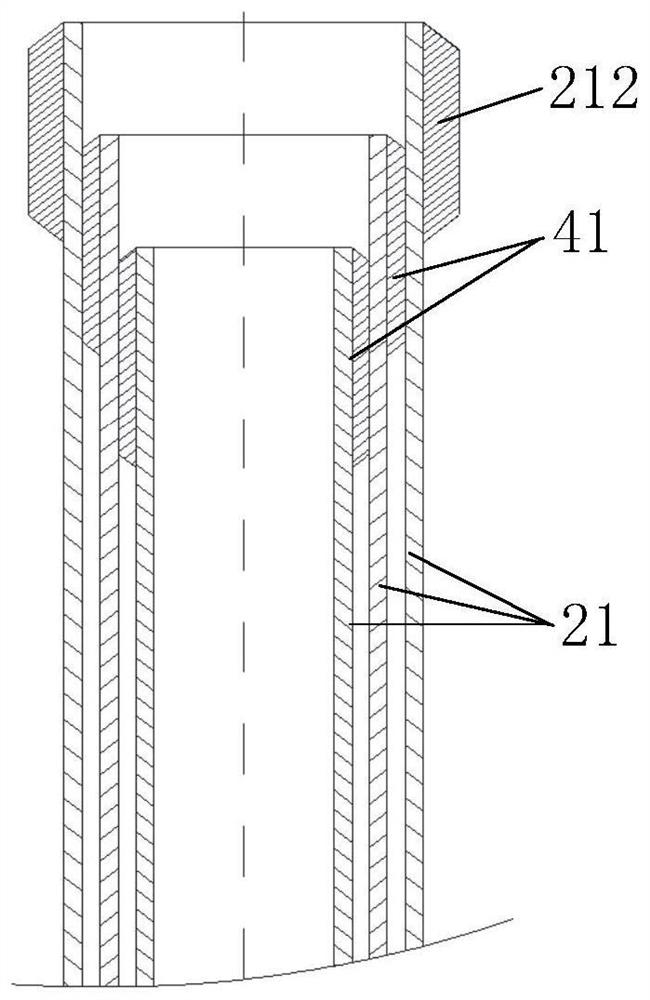

[0033] Such as Figure 1 to Figure 8 In the embodiment showing the perforating device for well completion operation, the perforating device for well completion operation is mainly used in the field of well completion and production stimulation of petroleum carbonate reservoirs. The perforating device for well completion includes a casing 1 and a nozzle assembly 2. One end of the nozzle assembly 2 is set in the casing 1;

[0034] In this embodiment, the nozzle assembly 2 includes a spray hose 21 and a combined spray head 22 . Wherein, there are a plurality of spray hoses 21, and the multiple spray hoses 21 are sheathed in turn, and the spray hoses 21 are stretched out step by step under the action of hydraulic traction to drill into the reservoir to implement po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com