A multi-slug step-by-step plugging method suitable for fractured formations

A plugging method and multi-slug technology, applied in the field of oil and gas field exploration and development, can solve problems such as cost increase, plugging particle waste, plugging layer damage, etc., to save facility costs, save plugging costs, and good plugging quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below according to the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of specific implementations. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all within the scope of protection. List.

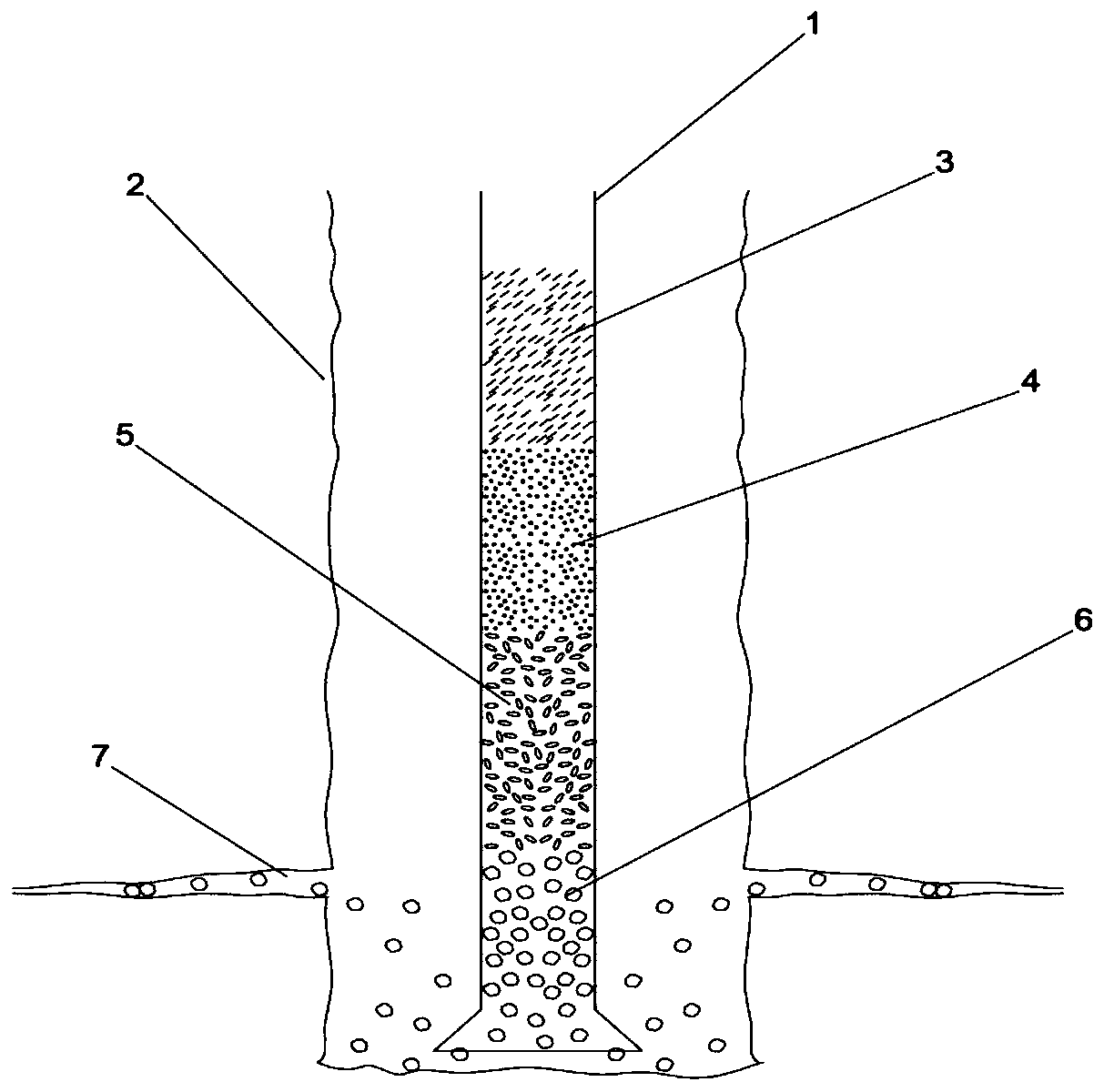

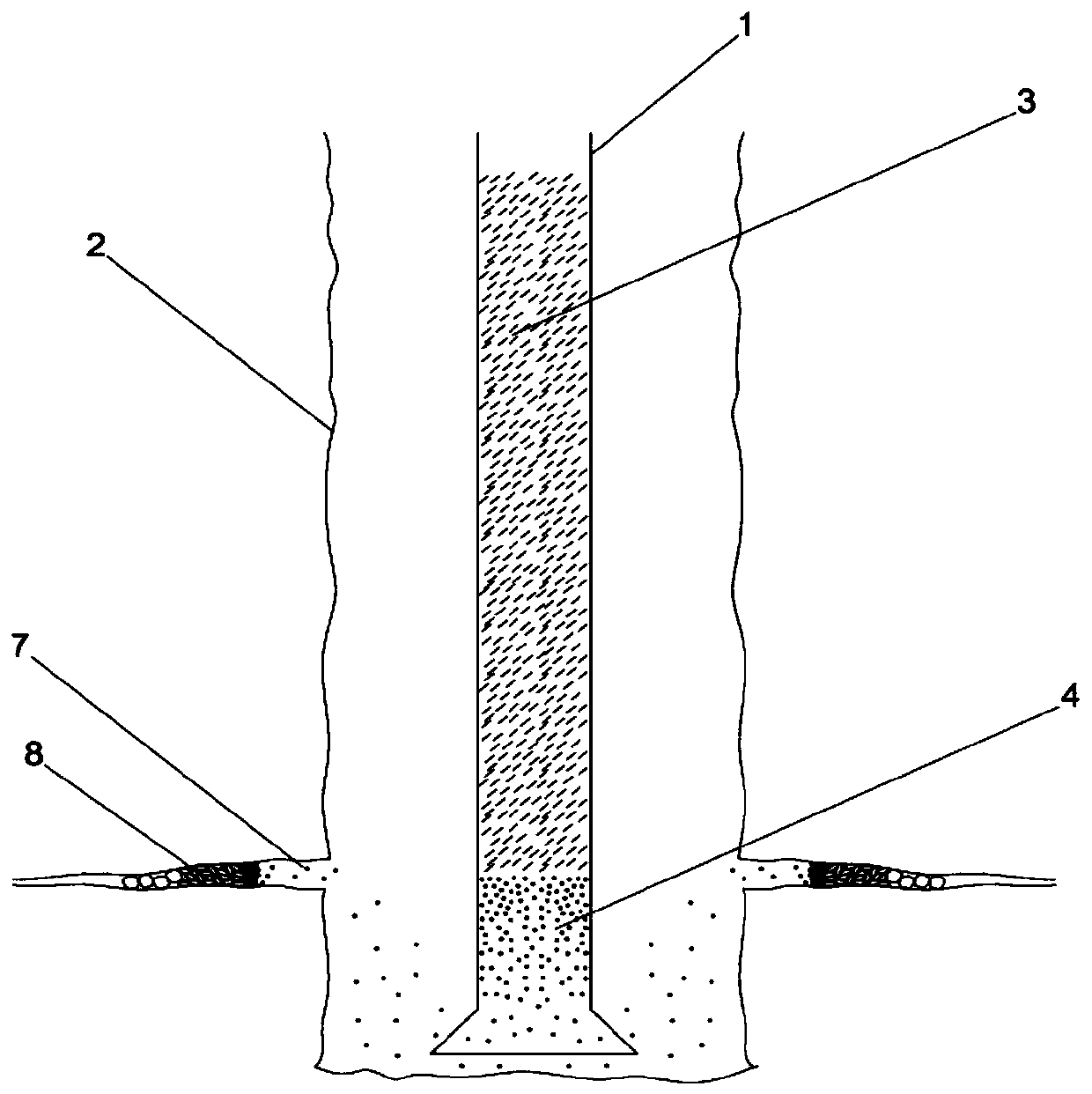

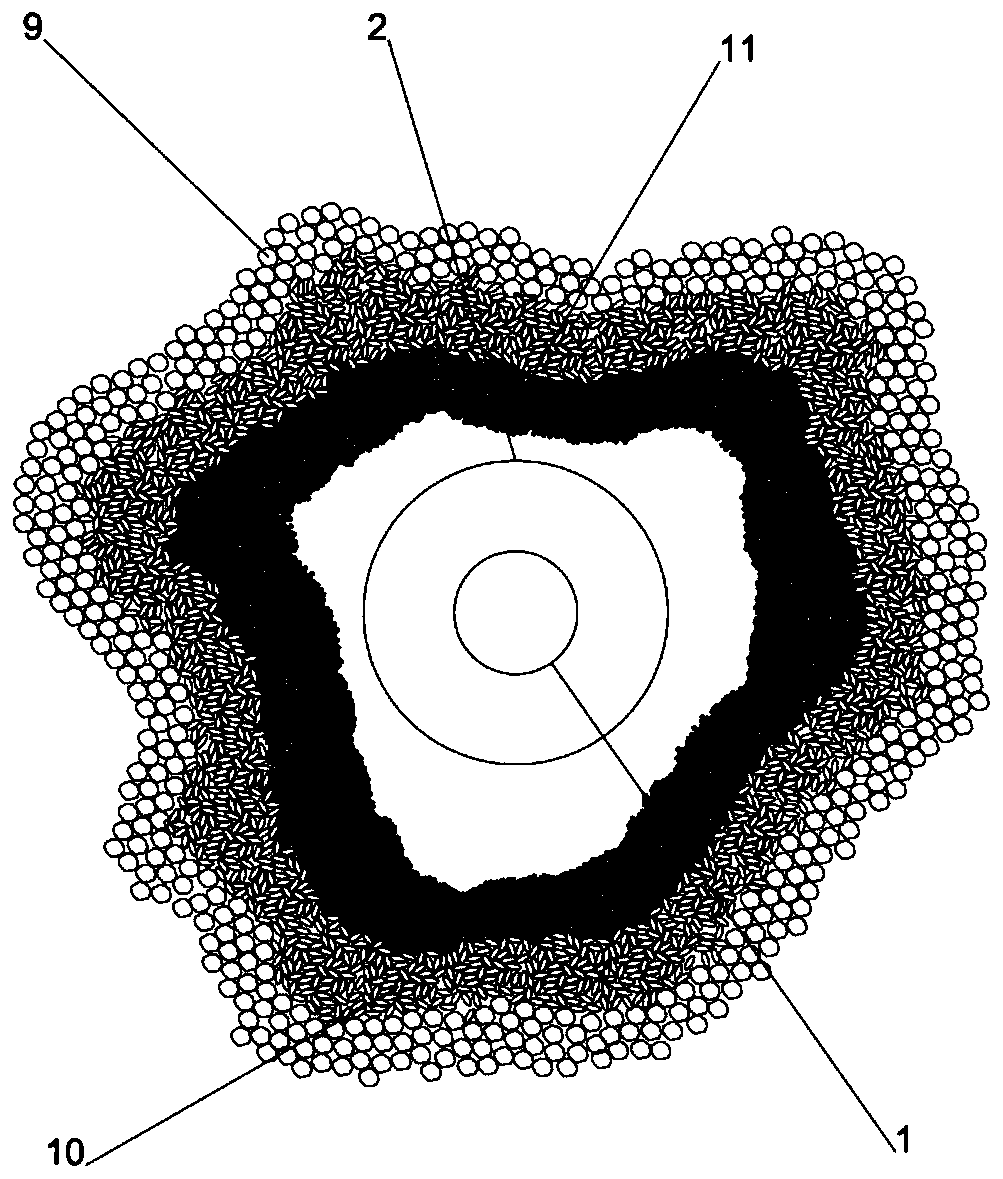

[0033] see figure 1 , figure 2 .

[0034] figure 1 , figure 2 It is a schematic diagram of the flow before and after plugging using the multi-slug staged plugging method. During the drilling process, the drill pipe 1 is located in the center of the well wall 2, and the drilling fluid 3 enters the bottom of the well through the drill pipe 1, and then flows through the annulus between the drill pipe 1 and the well wall 2 and returns to the ground. When the formation is dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com