Making method of modular moss wall

A production method and technology of moss walls, which are applied in the field of modular moss wall production, can solve the problems of inconvenient installation of modules and easy falling off of moss, and achieve the effects of many fixing points, good water permeability and drainage, and flexible fixing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

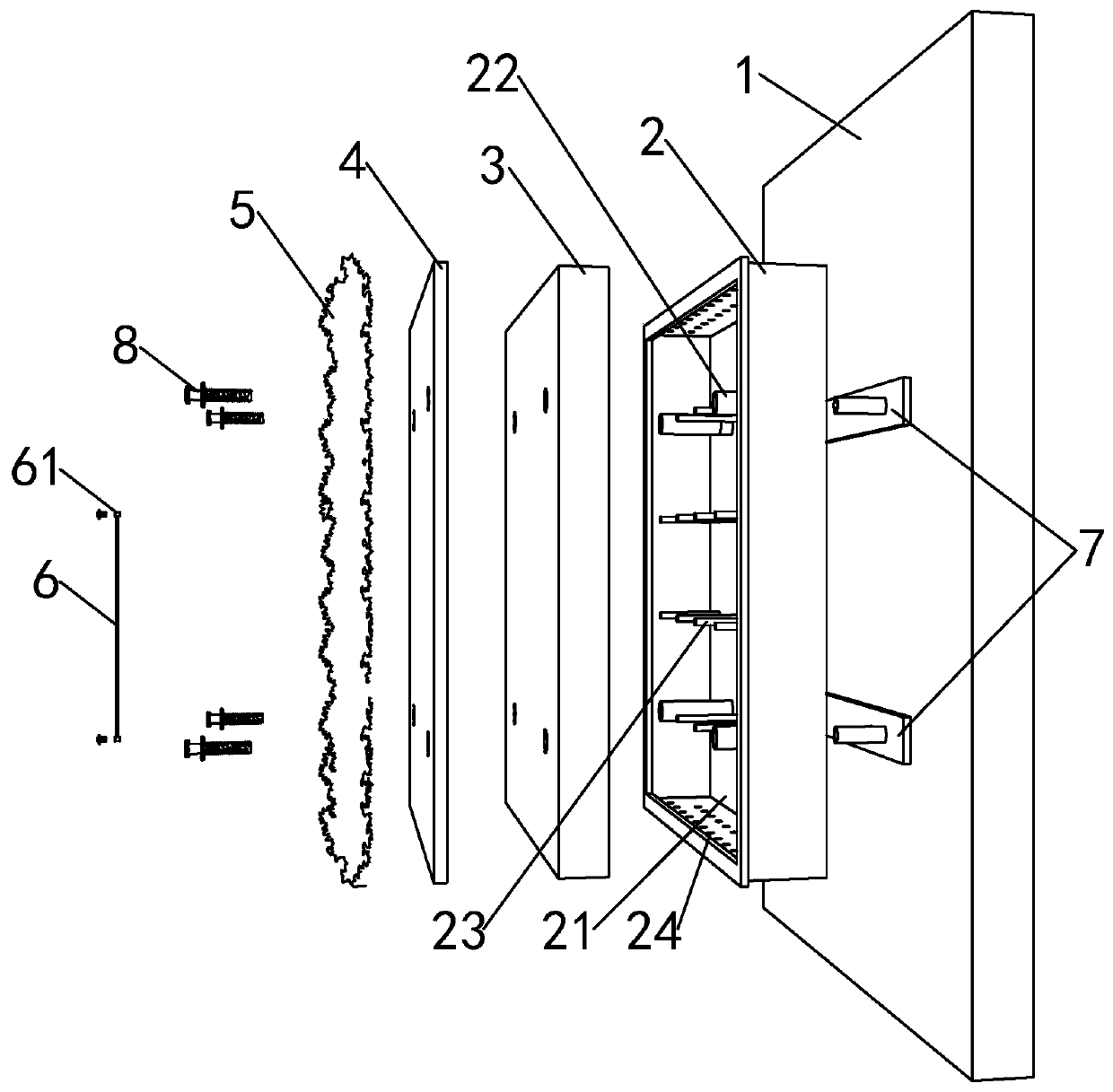

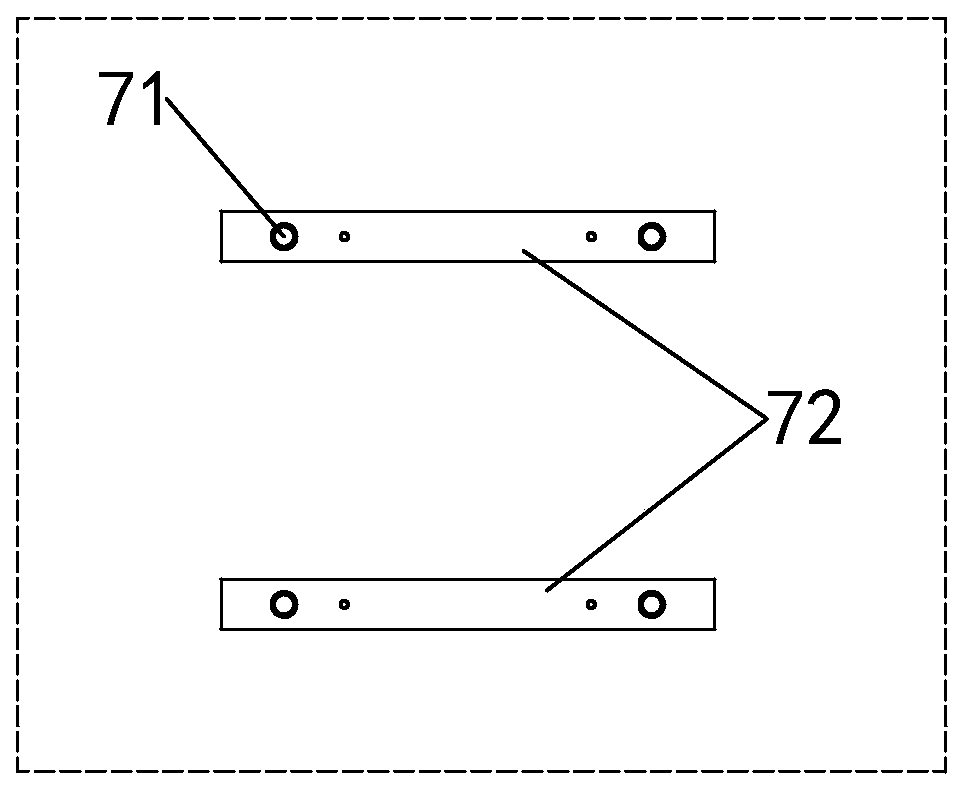

[0027] refer to Figure 1 to Figure 3 , the present invention is a kind of manufacture method of modular moss wall, comprises the following steps:

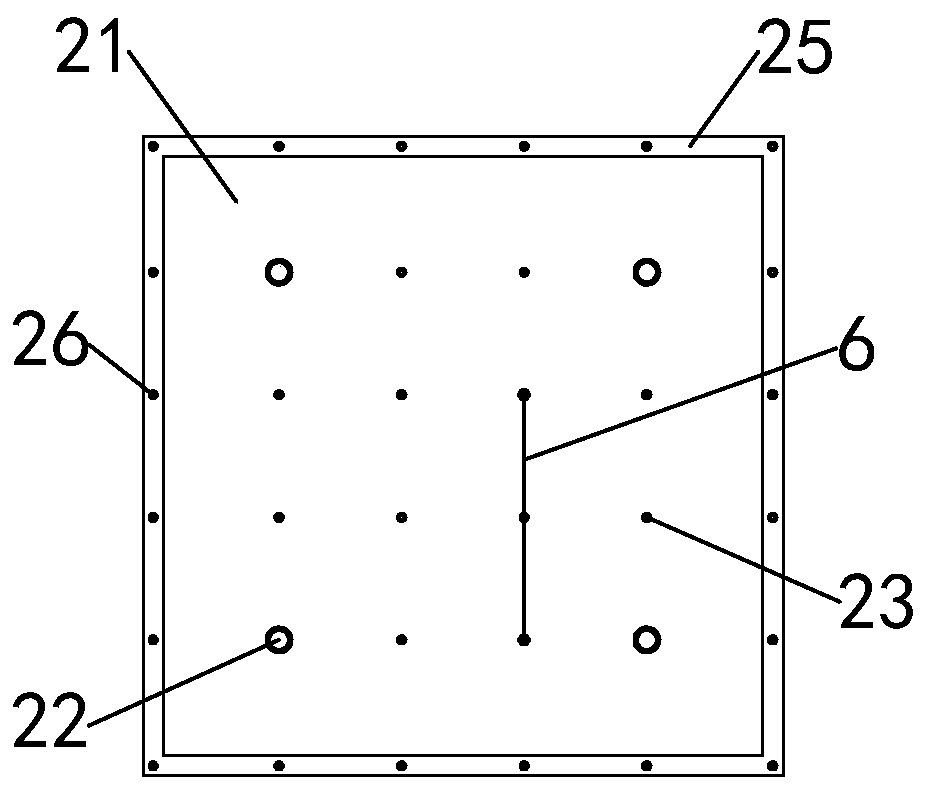

[0028] S1. Making the module base plate 2: the module base plate 2 is a frame body with a base plate 21, and the inner side of the base plate 21 is provided with a plurality of second fixed shafts 23 arranged at intervals, and the free ends of the second fixed shafts 23 are provided with internal thread, the second fixed shaft 23 can play the role of moss fixed belt 6 fixed points, and the arrangement interval of the second fixed shaft 23 itself can become the fixed attachment point of moss in the moss growth process, forming the effect of "reinforced concrete", especially It is better for some cushion-like and thick moss;

[0029] S2. Constructing the water-retaining matrix layer 3: several openings corresponding to the second fixed shafts 23 are opened on the water-retaining matrix layer 3, and the openings are correspondingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com