Simulated circuit fault testing method based on sequential testing

A technology for simulating circuit faults and testing methods, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as affecting the efficiency of the fault identification process, ignoring the difference of effective information, and lack of flexibility in the modeling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

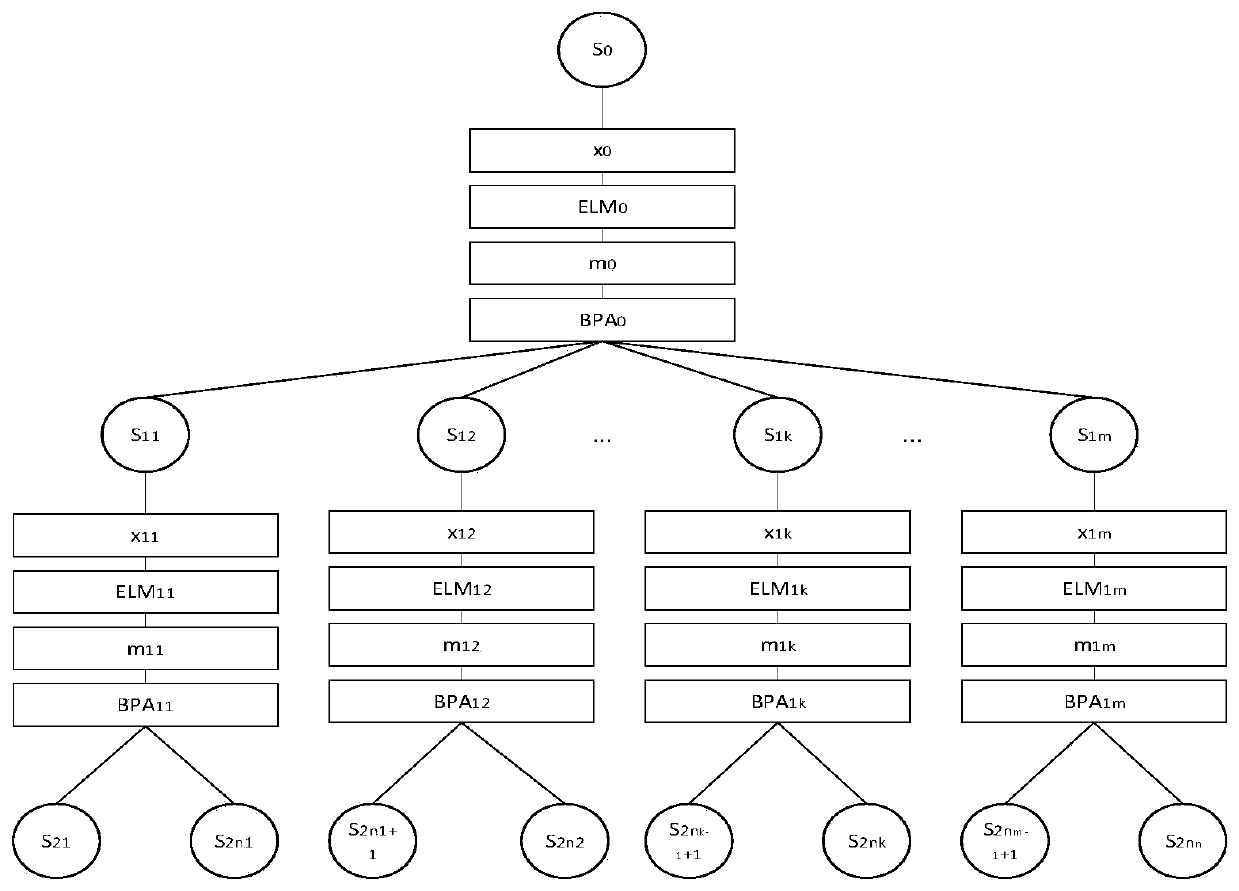

[0061] figure 1 It is a flowchart of an analog circuit fault testing method based on sequential testing in the present invention.

[0062] In this example, if figure 1 Shown, a kind of analog circuit failure testing method based on sequential test of the present invention comprises the following steps:

[0063] S1: Acquisition of voltage values at different corner frequencies

[0064] Collect the voltage eigenvalues of N groups of samples at different corner frequencies in the fault state and healthy state of the analog circuit, denoted as X={x 1 ,x 2 ,...,x N}, where the voltage eigenvalue xi={x i,1 ,x i,2 ,...,x i,k ,...,x i,T},x i,k is the voltage characteristic value of the i-th sample collected at the k-th corner frequency, and T is the number of corner frequencies;

[0065] Construct the expected output vector Y={y of each sample 1 ,y 2 ,...,y i ,...,y N}, where y i ={y i,1 ,y i,2 ,y i,3 ,...y i,j ,...,y i,M}, M is the total number of fault states...

example

[0111] In order to illustrate the technical effects of the present invention, an analog circuit is taken as an example to verify the implementation of the present invention. Such as image 3 As shown, the circuit is composed of 4 second-order filters and an adder, and it is modeled and simulated using Pspice software. The tolerance of R1, R2, R3, R4, R5, R6, R7 and R8 is ±10%, the tolerance of C1, C2, C3, C4, C5, C6, C7 and C8 is ±5%, the gain of the amplifier is Av1 , the tolerance of Av2, Av3 and Av4 is ±1%, and the tolerance of R9, R10 and R11 is ±1%. Analysis shows that the circuit has 4 corner frequencies: 10Hz, 100Hz, 10kHz and 100kHz. The probability of a single fault in an analog circuit accounts for about 80%, so only the state monitoring and health management of a single fault is considered.

[0112] Set Av 1 ,Av 2 ,Av 3 and Av 4 In (1.1~1.5%)Xn, (1.6~2%)Xn, (2.1~2.5%)Xn, (2.6~3.0%)Xn, (3.1~3.5%)Xn, (3.6~4.0%)Xn, ( 4.1~4.5%)Xn, (4.6~5.0%)Xn, (5.1~5.5%)Xn, (5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com