Multi-storied warehouse, multi-storied warehouse wall and manufacturing method of multi-storied warehouse wall

A production method and wall technology, applied in the field of building warehouses, can solve the problems of low bending strength, low rigidity of solid brick walls, environmental pollution, etc., and achieve the goal of ensuring rigidity and bending strength, high construction efficiency, and avoiding environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

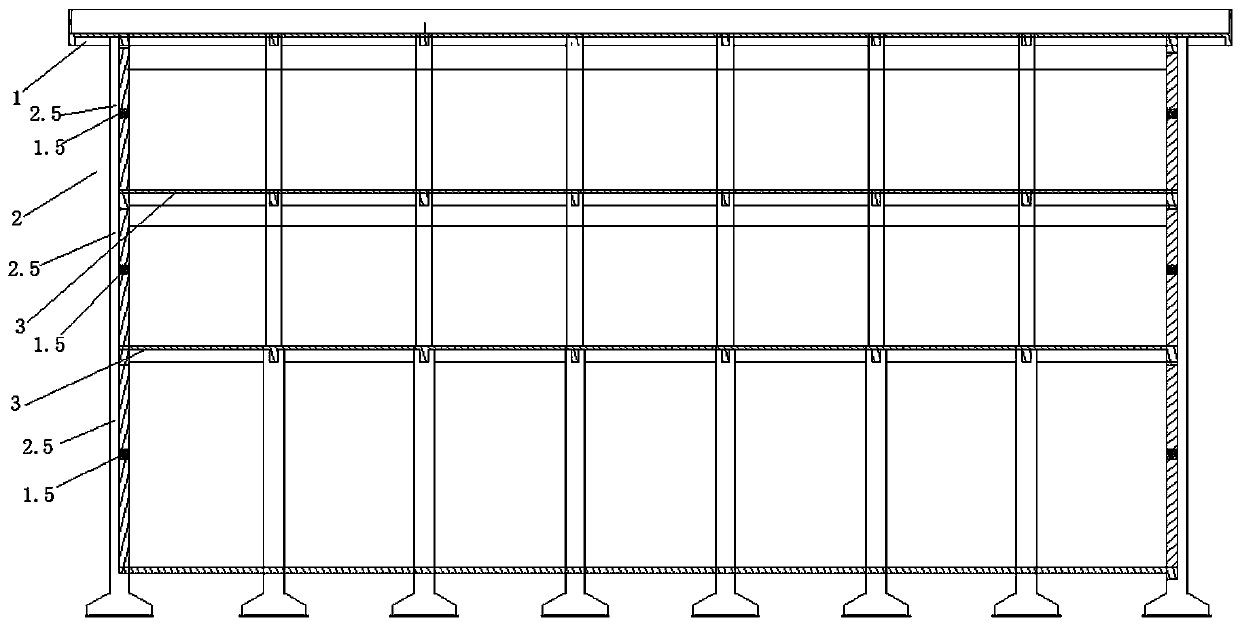

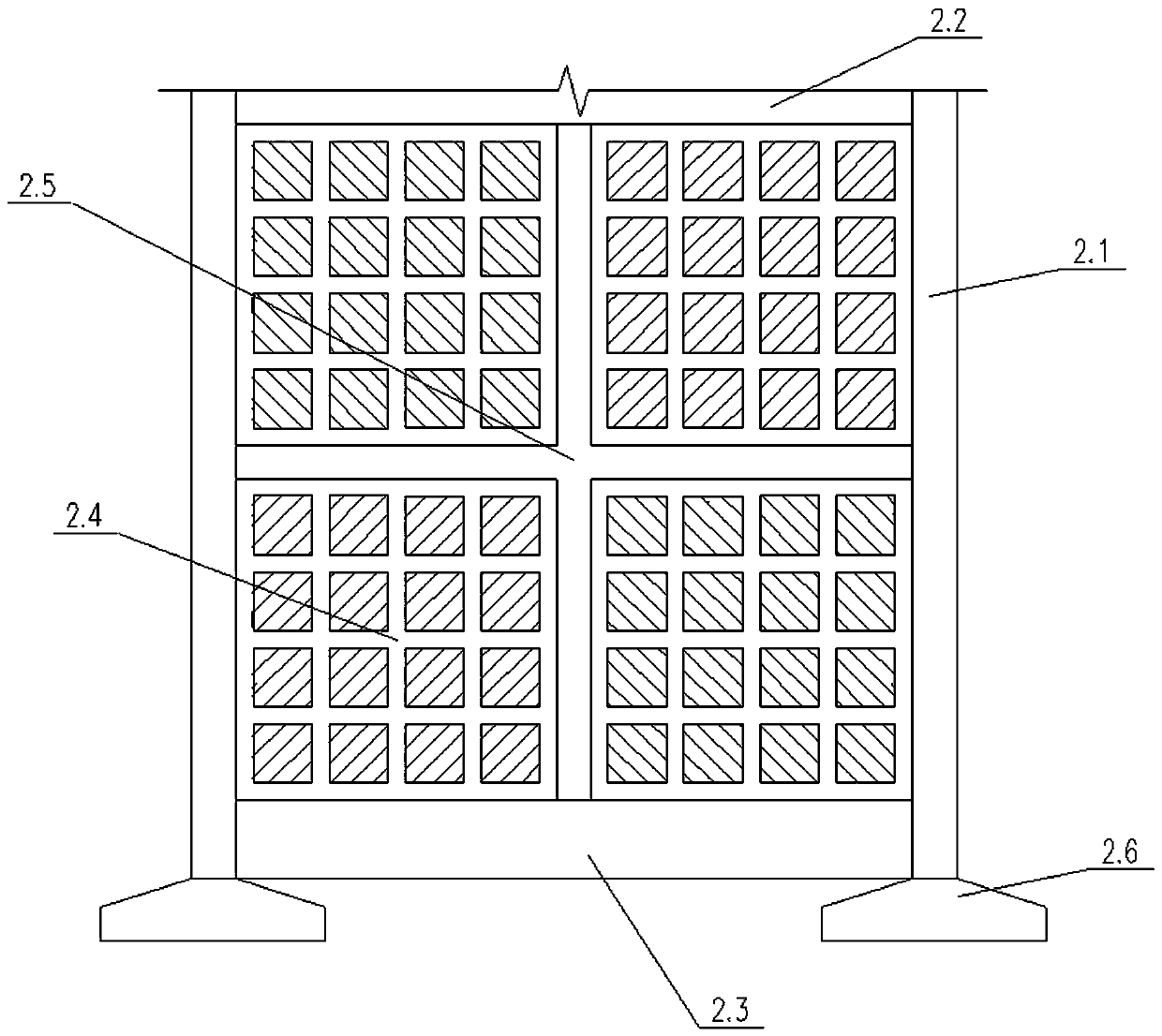

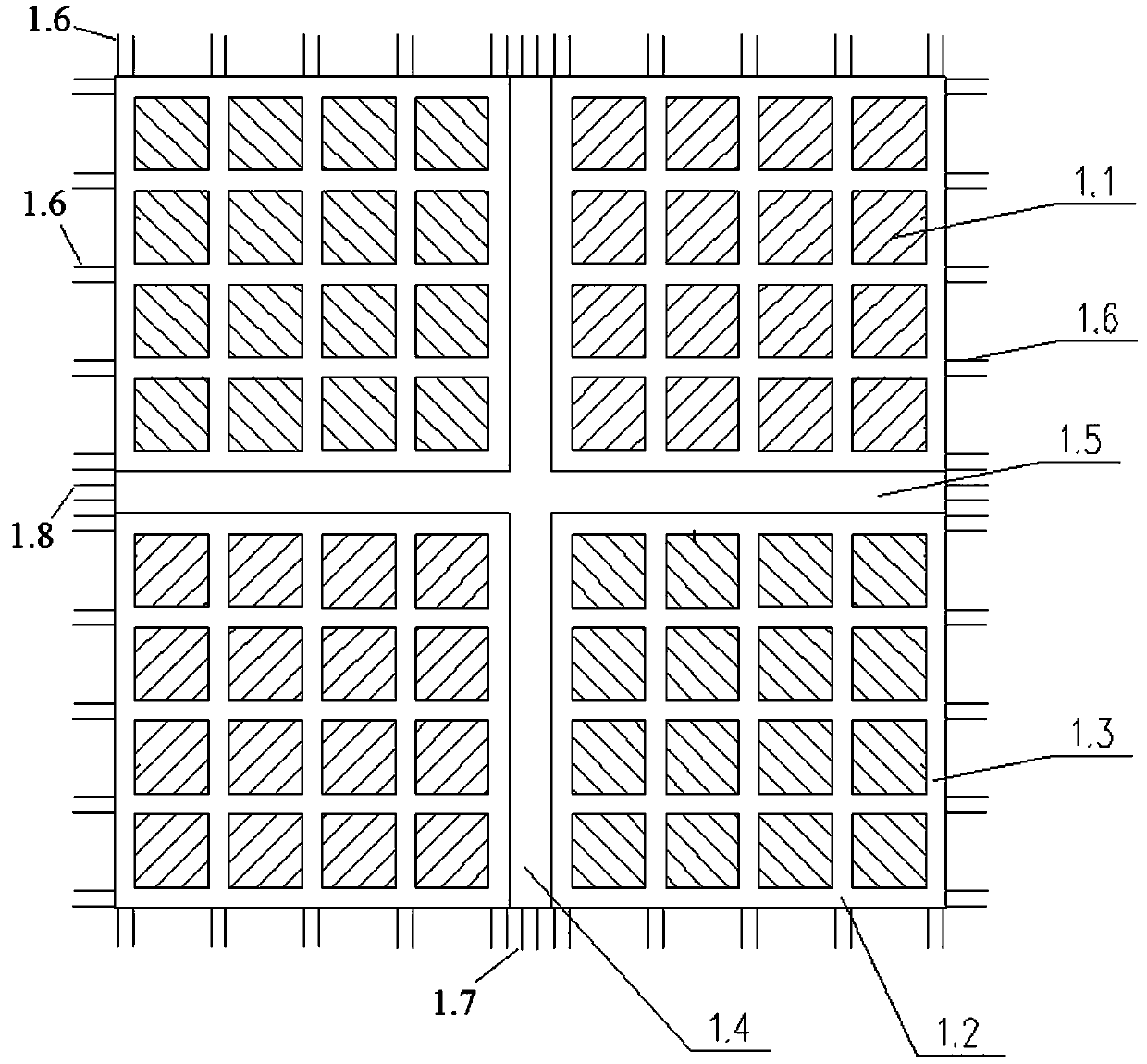

[0024] An example of a building warehouse is Figure 1~4 Shown: including the surrounding walls 2 and the warehouse roof 1 arranged on the top of the wall, the interior of the building warehouse is divided into three layers by the partition 3. The wall includes a plurality of frame columns 2.1 arranged side by side, and at least two frame beams 2.2 arranged at intervals up and down are arranged between the frame columns 2.1, wherein the lowermost frame beam is a ground beam 2.3, and the bottom of each column is provided with Concrete foundation 2.6, the two ends of the ground beams are also connected to the corresponding foundation respectively. Composite wall panels 2.5 are arranged between adjacent frame columns and corresponding adjacent frame beams. The composite wall panels include hidden columns 1.4 and hidden beams 1.5 arranged vertically and horizontally. The hidden columns 1.4 and hidden beams 1.5 connect the adjacent frame columns The space enclosed by the adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com