Bridge crane general assembly technology

A technology for bridge cranes and cranes, which is applied in the direction of walking bridge cranes, cranes, and traveling mechanisms, and can solve problems such as high difficulty in hoisting, limited space, and complex working conditions for crane assembly, so as to reduce construction difficulty and reduce work volume, eliminating the effect of being unable to turn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0050] There are two types of bridge cranes: 100T and 200T. This process plan is only described for 200T bridge cranes. For 100T bridge cranes, you can refer to this process.

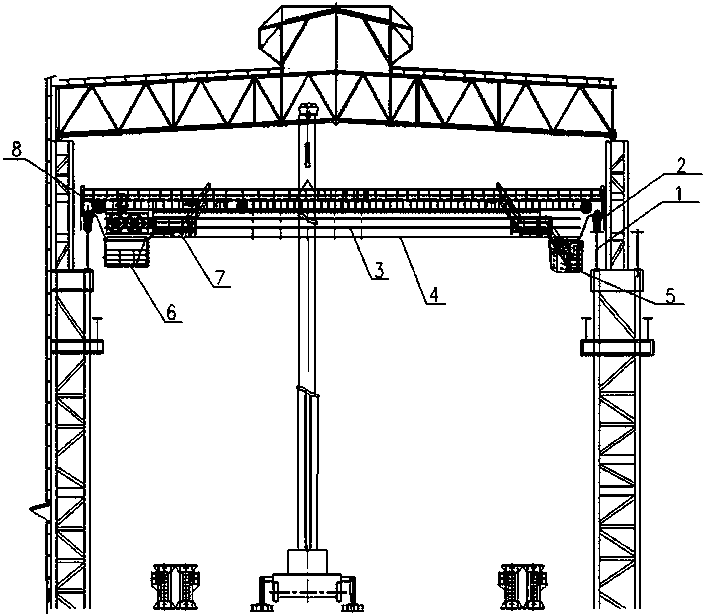

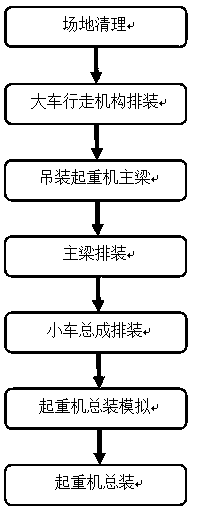

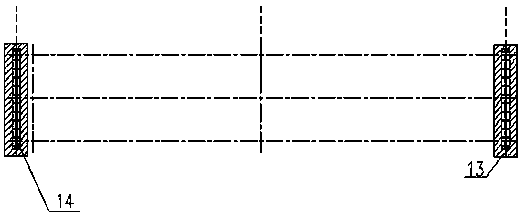

[0051] A bridge crane assembly process, the specific structure of the crane is as follows figure 1 As shown, the specific structure of the bridge crane mainly includes a rail bearing beam 1, a cart traveling mechanism 2, a main beam 3 placed on the cart traveling mechanism, a lifting mechanism 8 installed on the main beam, and a trolley track 4 , the driver's cab 5 placed under the main beam, the maintenance cage 6 and the trolley assembly 7 placed on the track of the trolley, the upper surface of the rail bearing beam needs to be adjusted to a horizontal state with the help of a laser, and the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com