Automatic feeding device for aquatic feed

An aquafeed, automatic technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

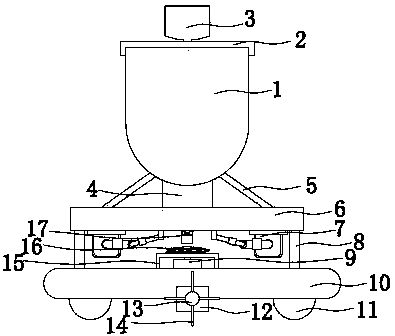

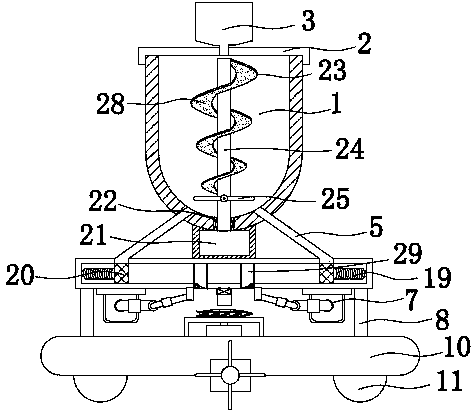

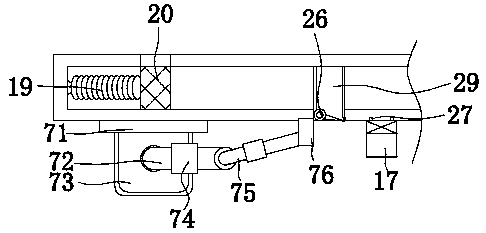

[0022] Such as Figure 1-6 As shown, an automatic aquatic feed feeding device includes a hopper 1, the top of the hopper 1 is covered with a hopper cover 2, the upper part of the hopper cover 2 is connected to the feeding box 3, the bottom of the hopper 1 is connected to the collection box 6 through the motor box 4, and the hopper 1 The interior of the motor box 4 is equipped with a conveying assembly, and the two sides of the motor box 4 are inclined to be provided with a symmetrical feeding pipe 5. The feeding end and the discharging end of the feeding pipe 5 are respectively connected to the hopper 1 and the collecting box 6. Symmetrically arranged support columns 8 are fixedly connected to the lower surface, and a floating plate 10 is connected to the bottom of the support columns 8 . The feeding box set on the top of the device can mix various feeds, the mixed feed enters the hopper through the feeding box, the conveying component in the hopper conveys the feed, and the f...

Embodiment 2

[0031] An automatic aquatic feed feeding device of the present invention can be used for feeding various aquatic feeds. In actual use: the device can be fixed in one place or placed on the water surface. The propeller 14 rotates, and the propeller 14 drives the feeding device to move in the water, which is more flexible. The feeding box 3 on the top of the device can mix various feeds, and the mixed feed enters the hopper 1 through the feeding box 3, and the delivery assembly in the hopper 1 The feed is conveyed, and the feed is conveyed and stirred by the conveying component, which is beneficial to the mixing of various baits. Compared with ordinary bait feeders that use a single feed, this device feeds multiple feeds at one time after mixing, making up for the single feed. The nutritional deficiencies caused by feeding, while the floating feed is mixed with sinking and semi-sinking feeds for one-time feeding, the processed feed will enter the collection box 6 through the feed...

Embodiment 3

[0033] Contrast test: the ratio of the screw diameter of the screw blade of the present invention is 1:0.6~0.8:0.2~0.4, and the screw diameter ratio is compared with the screw diameter of the common screw blade in this ratio range, and it is not easy to break when it stirs the feed, and the particle size With high integrity, its absorption rate will also increase, and it will be more convenient and healthy to prey on aquatic products, and avoid the problem of indigestion. Figure 6 By comparison, it is known that the experiment was carried out under the condition that the average particle size of the particles was the same as the stirring time. (the screw diameter of helical blade of the present invention is experimental group, and the screw diameter of common helical blade is control group)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com