Current injection type mechanical high-voltage DC circuit breaker with input current direction selection

A technology of current direction and current injection, which is applied to circuit devices, emergency protection circuit devices, electrical components, etc., can solve the problems of bulky charging capacitors and inductive circuits, and achieve the effect of reducing arcing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

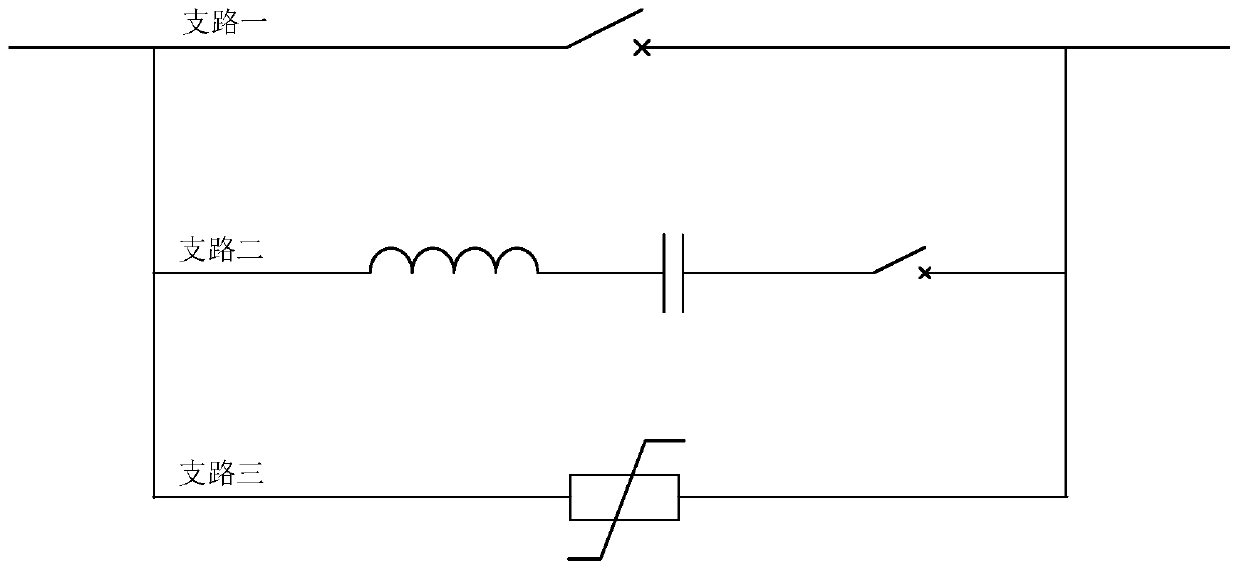

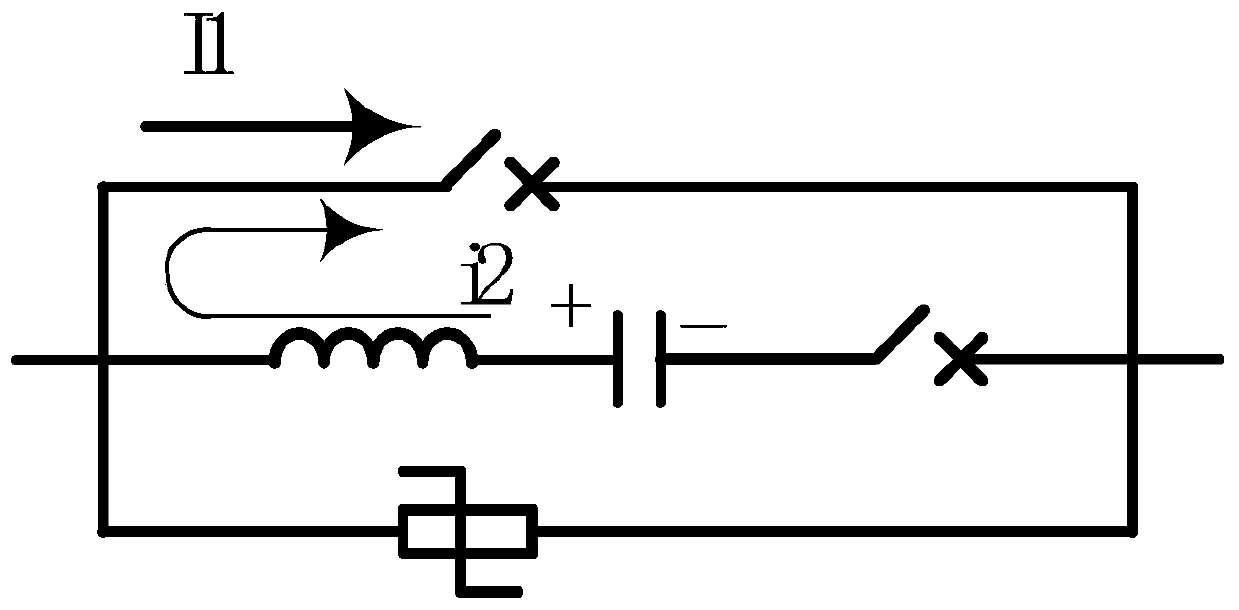

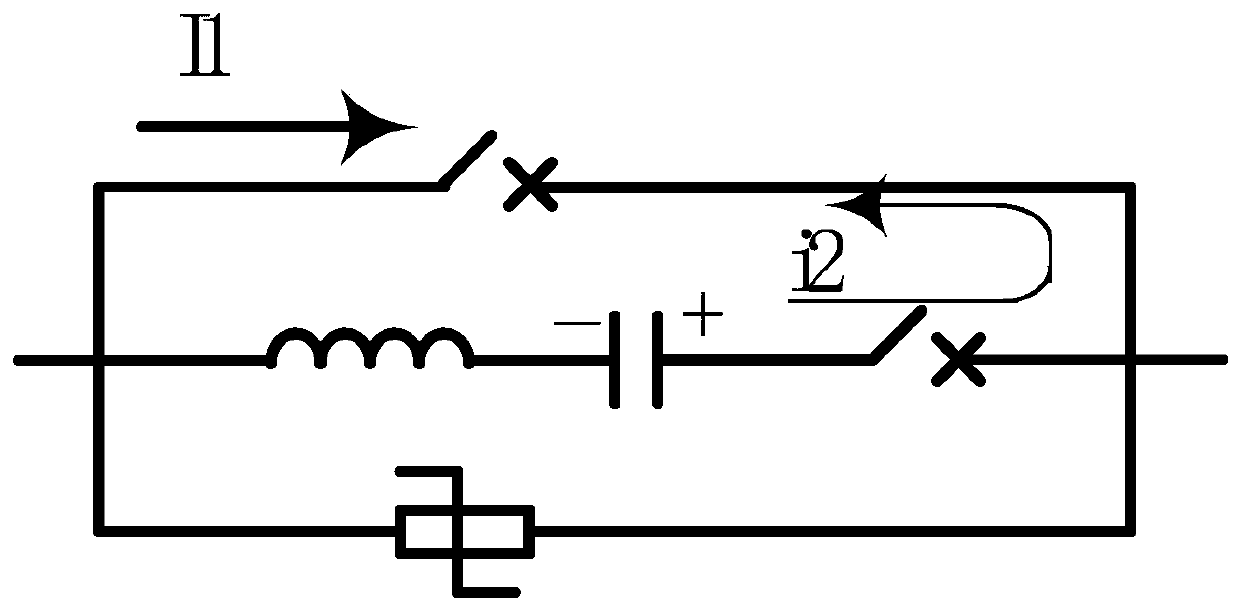

[0024] Such as Figure 5 As shown, the present invention provides a current injection mechanical high-voltage DC circuit breaker with input current direction selection, and replaces the IGCT electronic switch of the original mechanical high-voltage DC circuit breaker without current selectivity with a full-bridge rectifier module. Moreover, the controller used determines the time to invest in the current transfer branch and determines which group of thyristors to trigger according to the direction of the current flowing through the high-voltage vacuum circuit breaker. If the current flowing through the high-voltage vacuum circuit breaker is as Figure 7 As shown, the two thyristors T1 and T3 are triggered; if the current flowing through the high-voltage vacuum circuit breaker is as follows Figure 8 As shown, the two thyristors T2 and T4 are triggered. When the DC short-circuit current flows in different directions in the high-voltage vacuum circuit breaker, the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com