Anti-crushing and anti-deformation discharging device

A discharge device and anti-shattering technology, applied in sorting and other directions, can solve the problems of high-speed collision, deformation of the discharge hopper, scrapping, etc., and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

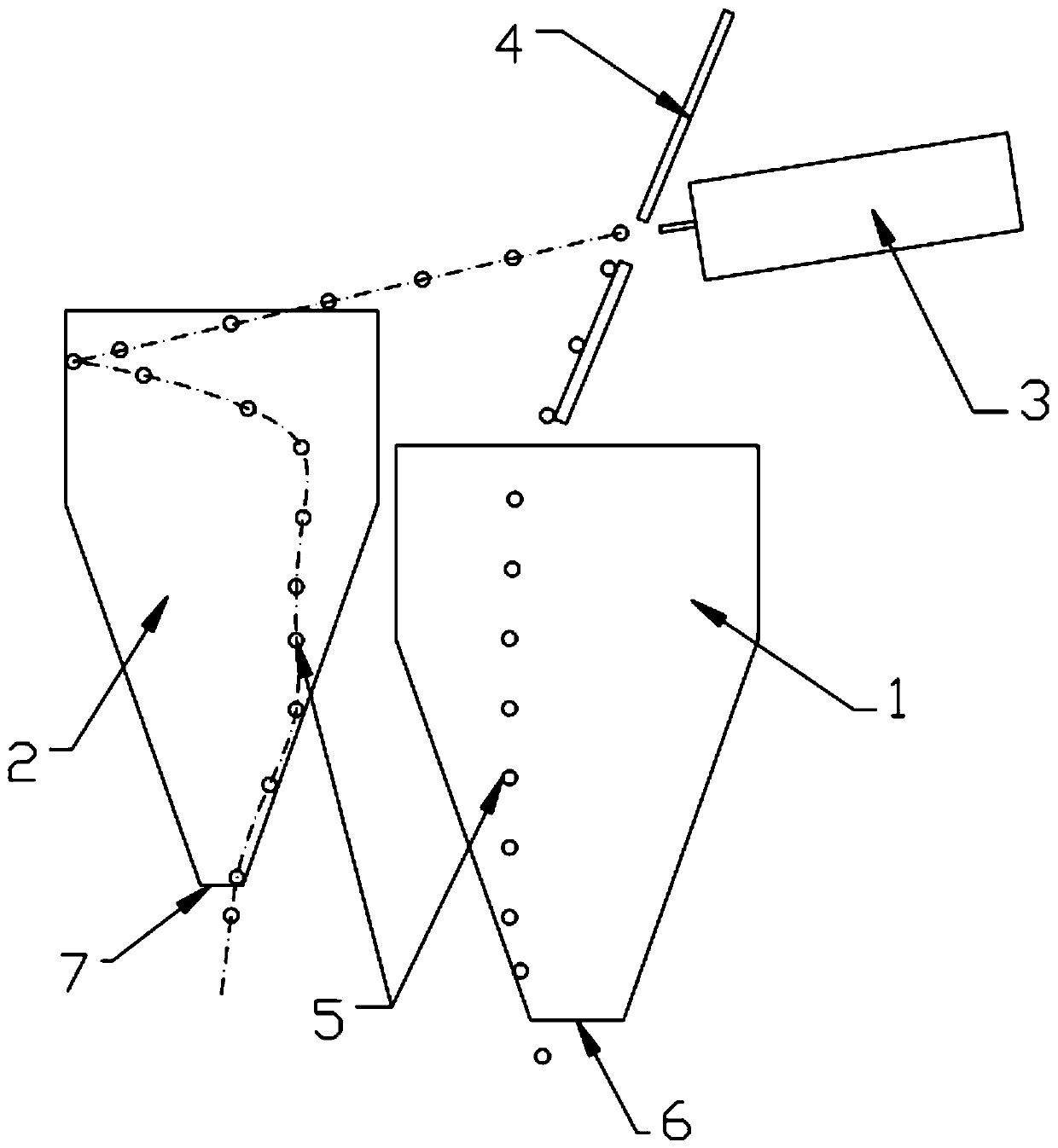

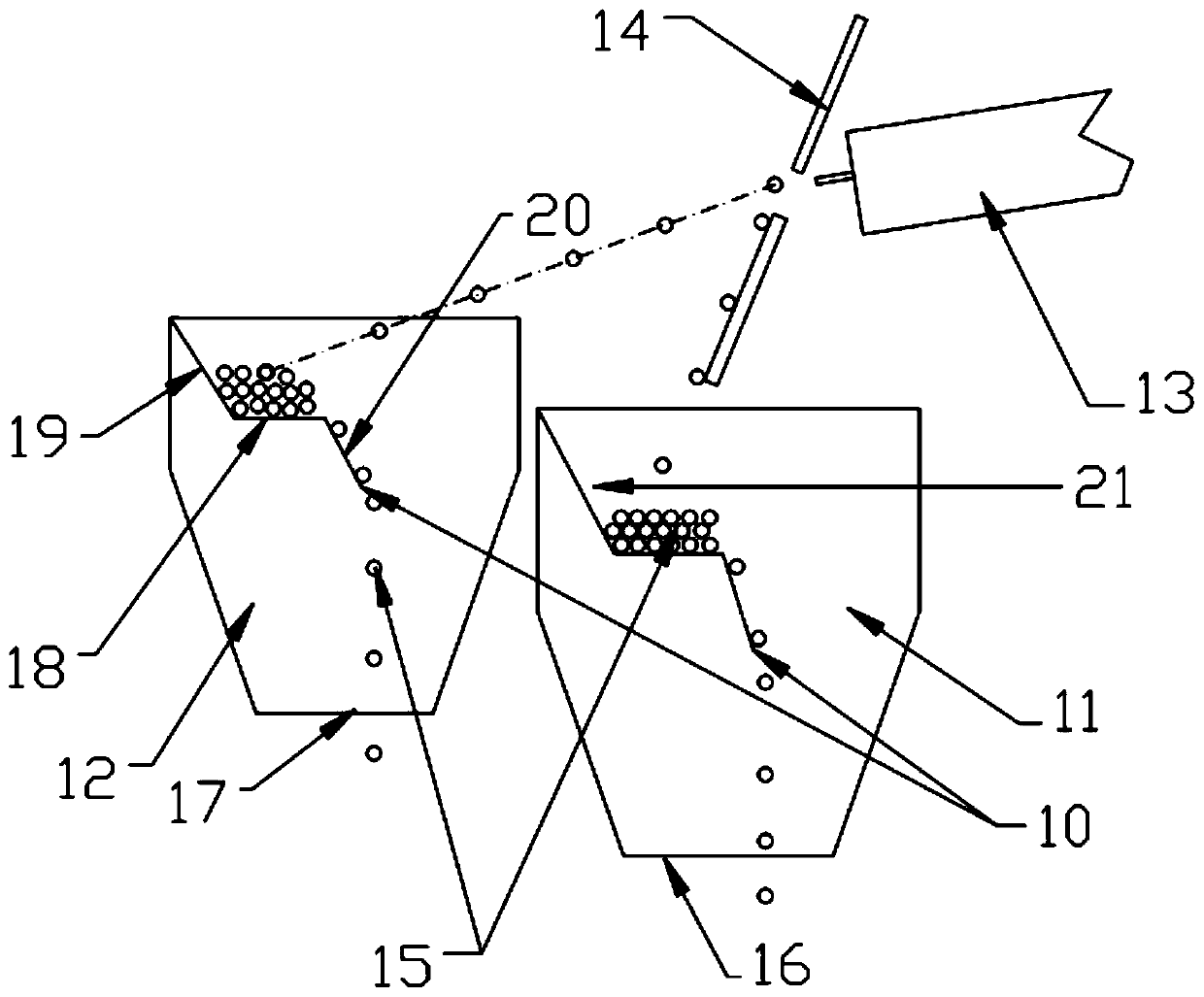

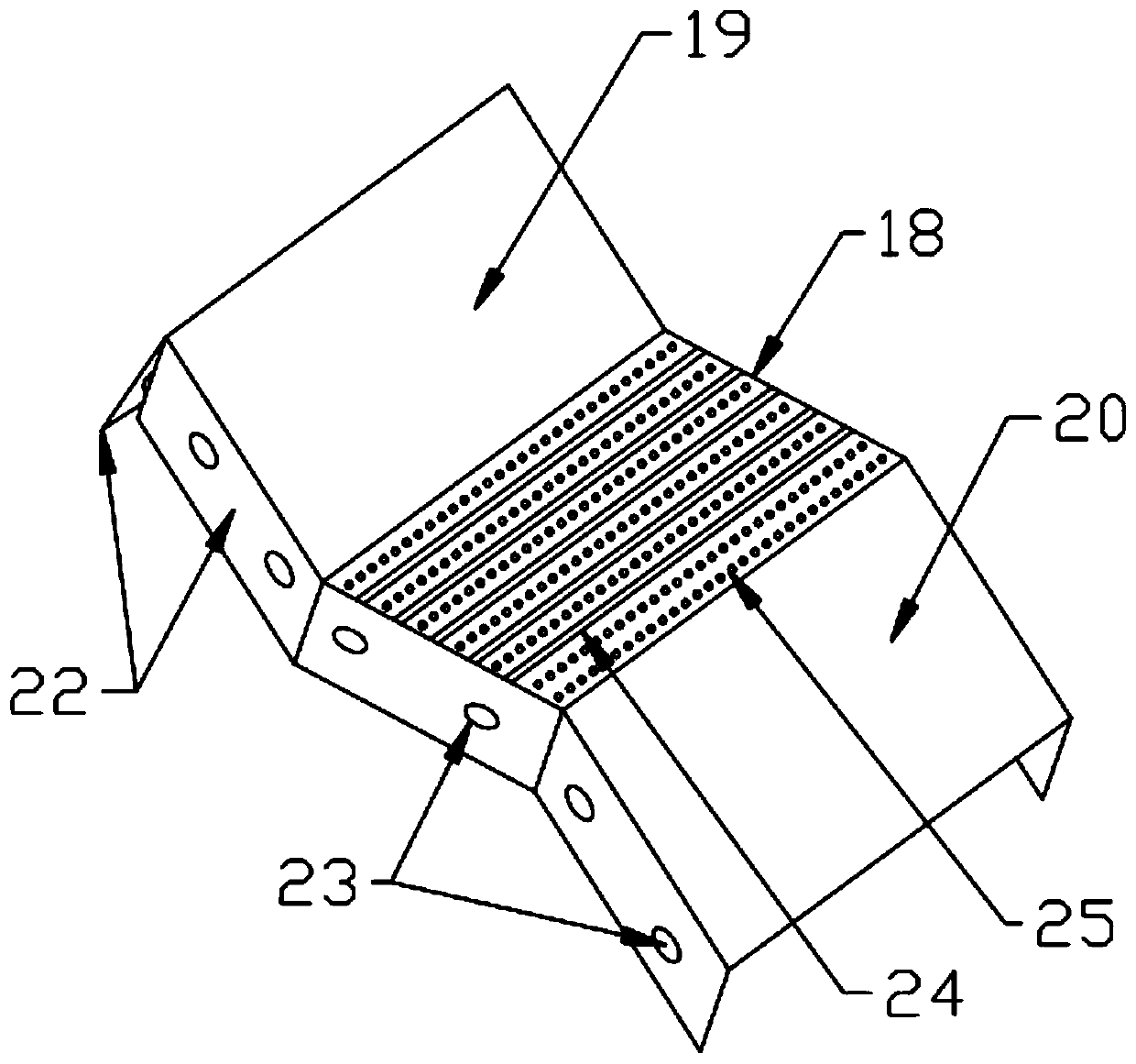

[0027] Such as figure 1 Shown in the prior art, is the schematic diagram of the discharge device structure of the color sorter, wherein there are finished product discharge hopper 1 and its discharge port 6, defective product discharge hopper 2 and its discharge port 7, color sorting device 4, guide Material device 7, as well as a schematic representation of the material path Figure 5 ,Depend on figure 1 It can be seen that the discharge path of the finished materials and defective materials after color selection, and the finished materials and defective materials will collide with the inner wall of the discharge hopper when they are discharged. Hard spar, etc., so that the discharge hopper will receive a very serious impact, which will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com