Air quantity control method and device for clean workshop

A technology for clean workshops and air volume control. It is applied in the control inputs involving users/components, heating and ventilation control systems, space heating and ventilation control inputs, etc., and can solve problems such as poor stability, large errors, and energy waste. , to achieve the effect of reducing energy consumption, ensuring pressure difference, and reducing redundant air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

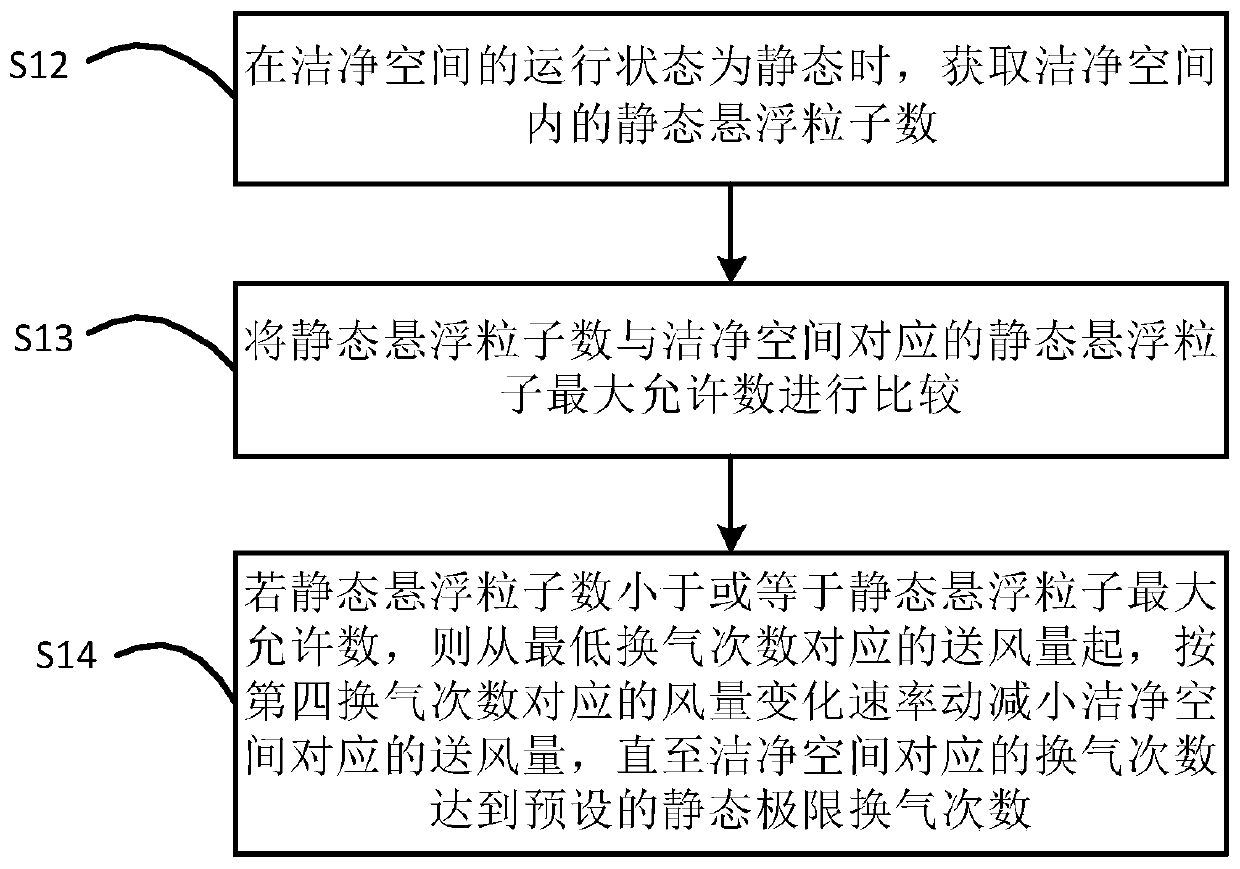

[0054] See attached figure 1 , figure 1 It exemplarily shows the main steps of the air volume control method for clean workshops, such as figure 1 As shown, the air volume control methods for clean workshops can include:

[0055] Step S1: Obtain the operating status of the clean space, including dynamic and static.

[0056]Specifically, the clean workshop includes a clean space, which may be a clean room, a clean corridor, etc. in the clean workshop. The operating state of the clean space includes dynamic and static. The dynamic means that there are process equipment and / or personnel (such as operators and engineers) in working condition i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com