Sewing machine and method for closing open end of tubular knitted article

A technology for sewing machines and knitted fabrics, which is applied in the field of sewing machines and weaving, and can solve problems such as inability to cut knitting sutures, loose weaving threads, and inability to cut weaving thread fragments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The positional relationships described in the following embodiments include: up, down, left and right. Unless otherwise specified, they are all based on the directions in which the components are drawn in the drawings.

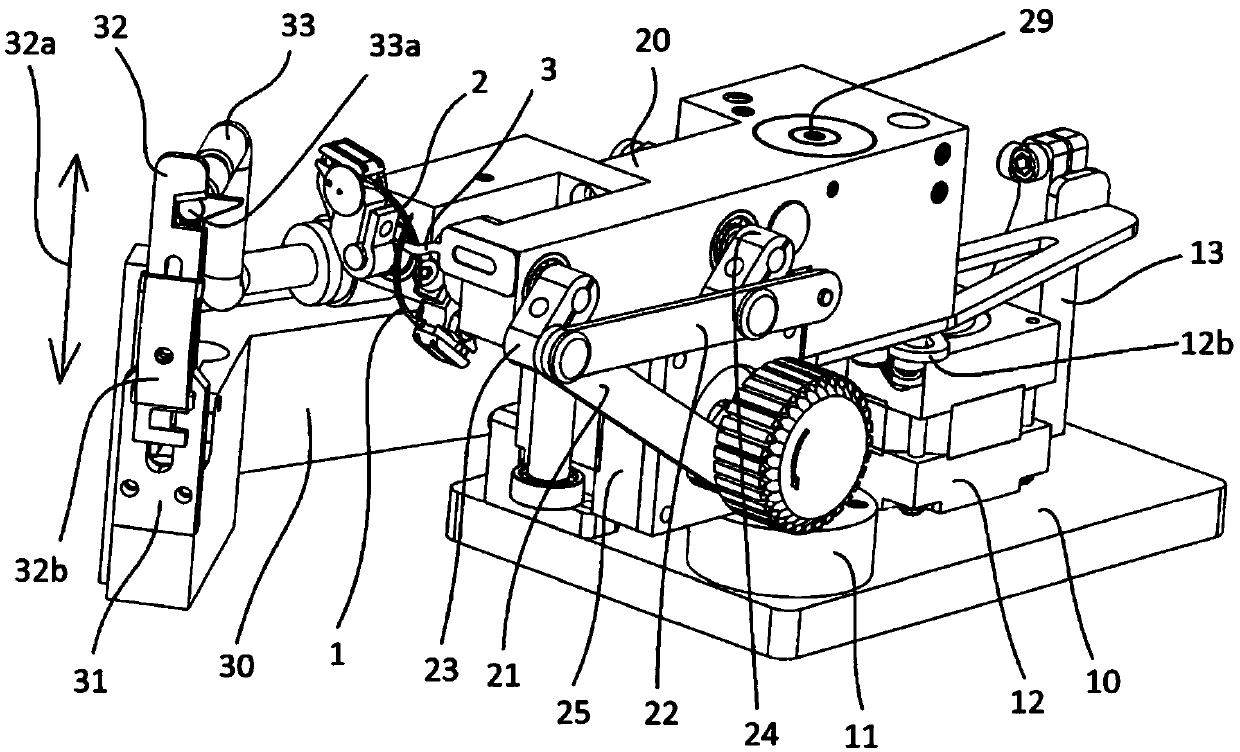

[0060] The embodiment provided by the present invention is a sewing machine, comprising a base (10); a sewing machine head (20) is rotatably arranged on the base (10) and pushed by a sewing machine head cam (11) of the base (10); The first motor (12), preferably a stepping motor, is arranged on the base (10), and the output end of the first motor (12) is provided with a bell crank (12a) and an arm (12b) connected, wherein One end of the arm (12b) is connected to the sewing machine head cam (11), so that the first motor (12) can drive the sewing machine head (20) to rotate around the rotating shaft (29). In addition, the moving mechanism of the aforementioned sewing machine head (20) can also be provided using a known linear mechanism.

[0061] One end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com