Ceramic tile binder, preparation method and using method

A ceramic tile adhesive and timely technology, applied in the direction of construction and building structure, can solve the problems of easy peeling, poor durability, weak adhesion, etc., and achieve the effect of saving material consumption, lasting performance and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

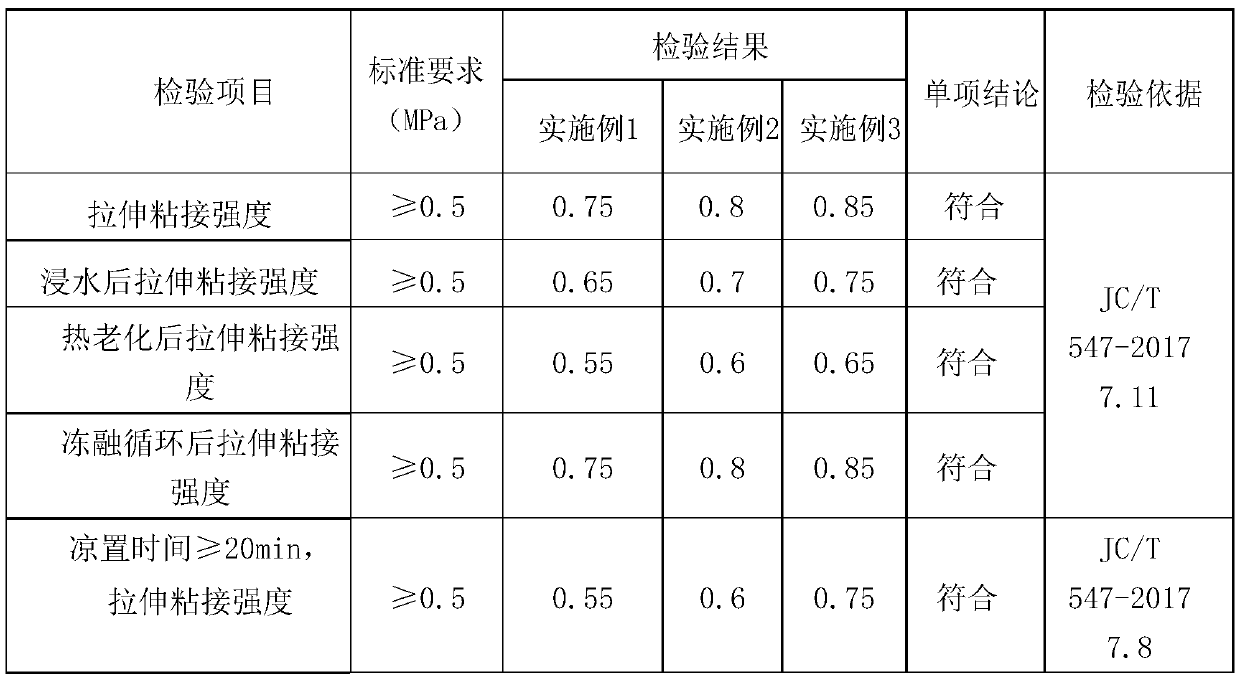

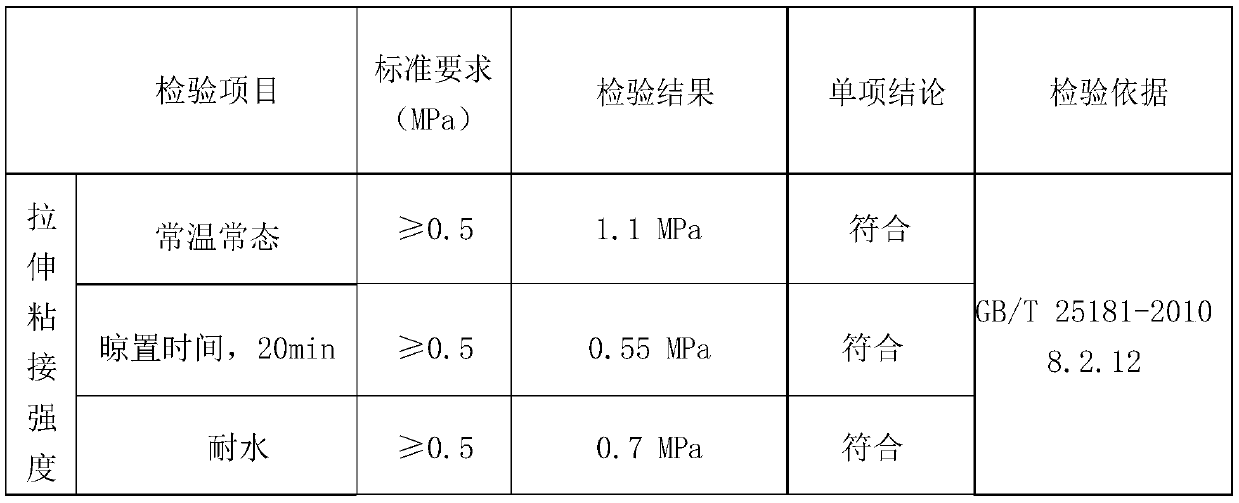

Examples

Embodiment 1

[0029] A ceramic tile adhesive comprises the following raw materials in parts by weight: 30 parts of high-quality cement, 65 parts of filler, 0.15 part of cellulose ether, and 0.5 part of redispersible rubber powder.

[0030] Further: the filler is quartz sand.

[0031] A preparation method of tile adhesive, the steps are as follows:

[0032] S1. Prepare various raw materials and preparation tools in advance according to the formula, turn on the tank agitator, then prepare according to the formula requirements, and fill in the preparation records in time;

[0033] S2. The order and quantity of chemical raw materials added must be strictly in accordance with the process formula, and should not be changed arbitrarily, and the remaining raw materials in the raw material barrel must be thoroughly cleaned;

[0034] S3. Neatly place it in the designated area. After stirring the binder, notify the quality inspection department to test its solid content;

[0035] S4. During the prep...

Embodiment 2

[0047] A ceramic tile adhesive comprises the following raw materials in parts by weight: 32 parts of high-quality cement, 68 parts of filler, 0.25 part of cellulose ether, and 0.7 part of redispersible rubber powder.

[0048] Further, the filler is river sand.

[0049] A preparation method of tile adhesive, the steps are as follows:

[0050] S1. Prepare various raw materials and preparation tools in advance according to the formula, turn on the tank agitator, then prepare according to the formula requirements, and fill in the preparation records in time;

[0051] S2. The order and quantity of chemical raw materials added must be strictly in accordance with the process formula, and should not be changed arbitrarily, and the remaining raw materials in the raw material barrel must be thoroughly cleaned;

[0052] S3. Neatly place it in the designated area. After stirring the binder, notify the quality inspection department to test its solid content;

[0053] S4. During the prepa...

Embodiment 3

[0065] A ceramic tile adhesive comprises the following raw materials in parts by weight: 35 parts of high-quality cement, 70 parts of filler, 0.35 part of cellulose ether, and 1 part of redispersible rubber powder.

[0066] Further: the filler is any combination of quartz sand, river sand and limestone.

[0067] A preparation method of tile adhesive, the steps are as follows:

[0068] S1. Prepare various raw materials and preparation tools in advance according to the formula, turn on the tank agitator, then prepare according to the formula requirements, and fill in the preparation records in time;

[0069] S2. The order and quantity of chemical raw materials added must be strictly in accordance with the process formula, and should not be changed arbitrarily, and the remaining raw materials in the raw material barrel must be thoroughly cleaned;

[0070] S3. Neatly place it in the designated area. After stirring the binder, notify the quality inspection department to test its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com