A split inspection robot

A patrol robot, split technology, applied in the field of robotics, can solve the problems of complex structure and easy damage of the automatic bayonet, and achieve the effect of improving the stability of travel, simple and compact structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

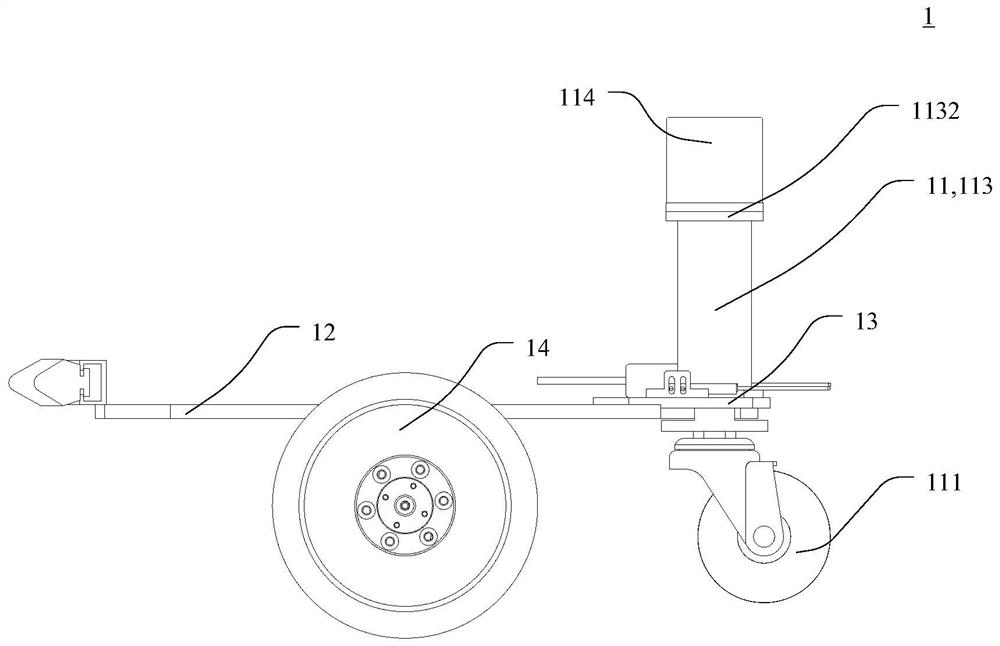

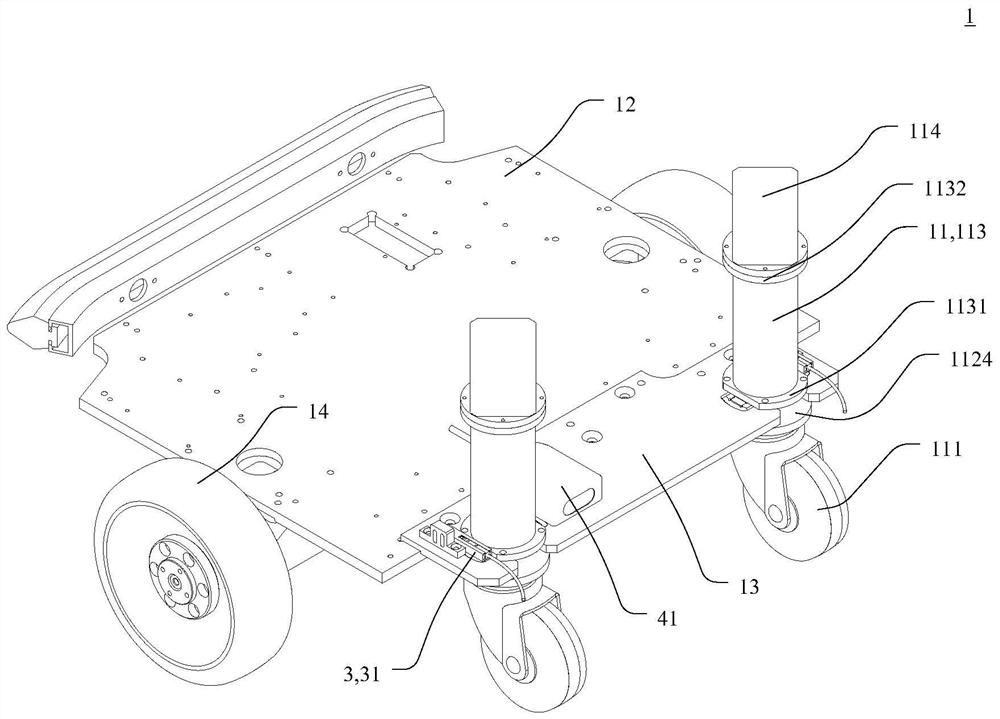

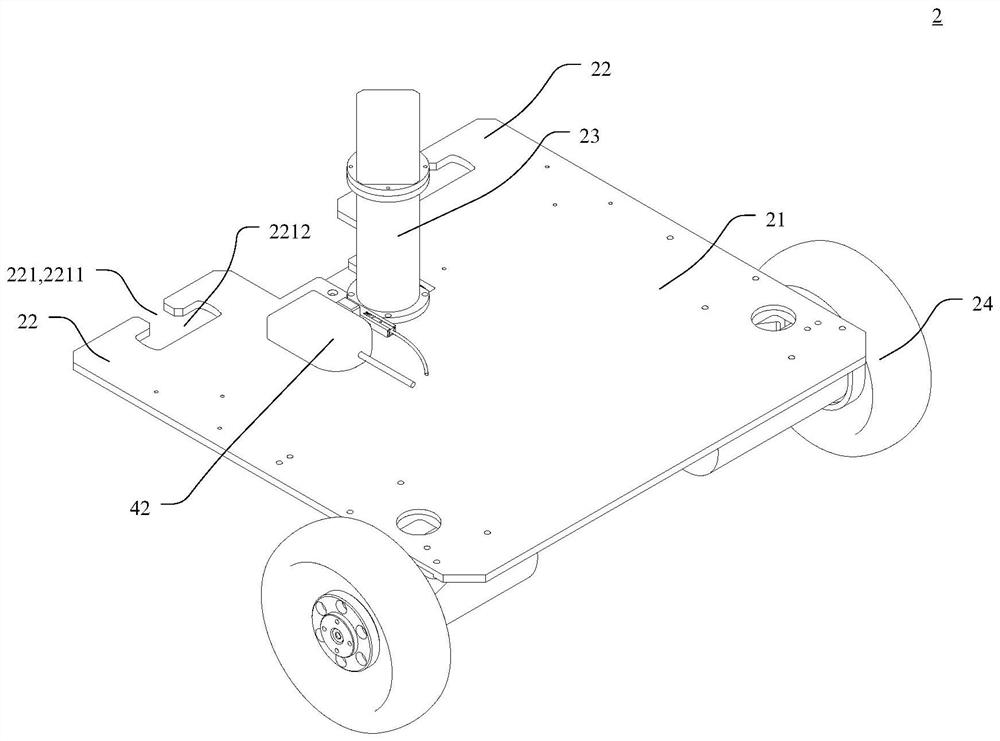

[0038] Such as Figure 1 to Figure 10 As shown, according to an embodiment of the present invention, a split inspection robot is provided, including a host, a slave, and a quick-disconnect and quick-connection mechanism. The quick-disconnect and quick-connect mechanism is used for locking and unlocking between the host and the slave, which is convenient Automatic combination and automatic disengagement of master and slave, such as figure 1 and figure 2 As shown, the quick release and quick connection mechanism includes a first wheel assembly 11 arranged on the host 1, the first wheel assembly 11 includes a first roller 111, the first roller 111 is a running wheel of the host 1, and the first wheel assembly 11 has a structure It is a telescopic structure to realize the lifting of the first roller 111, that is, the telescopic direction of the first wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com