A positioning welding tool for the nail planting cover plate assembly of the right front wheel cover of the automobile

A technology of positioning welding tooling and right front wheel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of easy loosening of cover plate assembly, skewed welding position of planting nails, and easy deformation of welding. , to achieve the effect of solving the welding deviation of planting nails, accurate welding position of planting nails, and reducing the deformation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

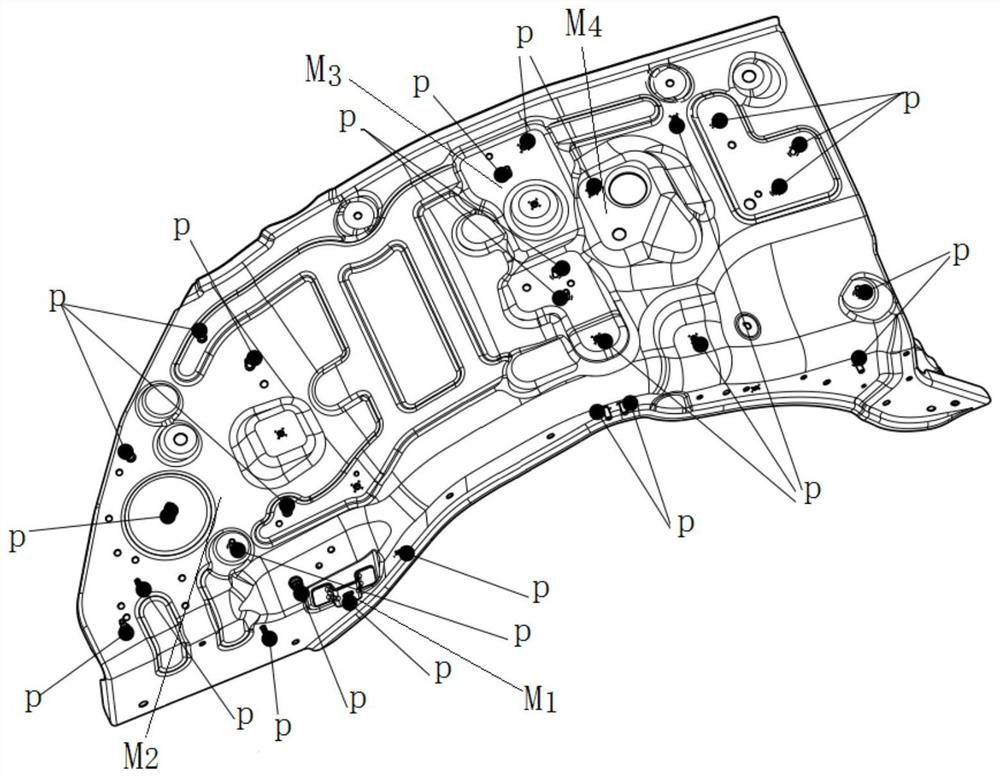

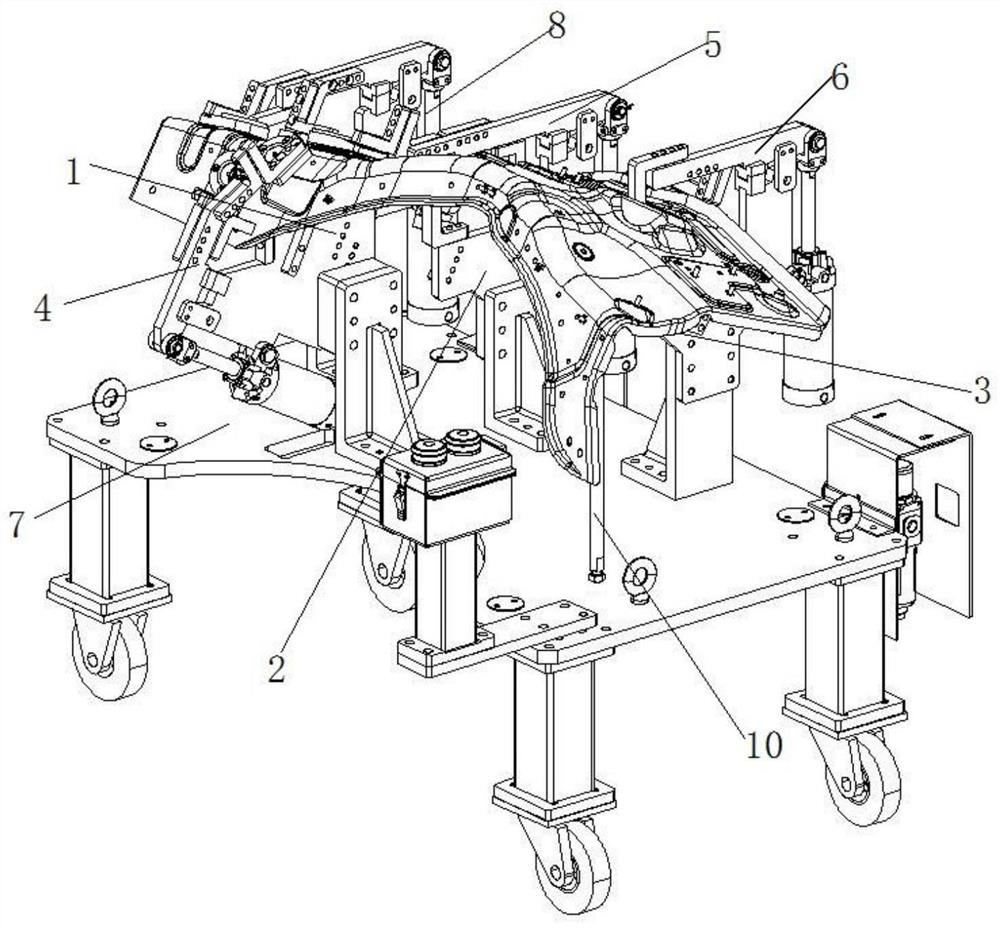

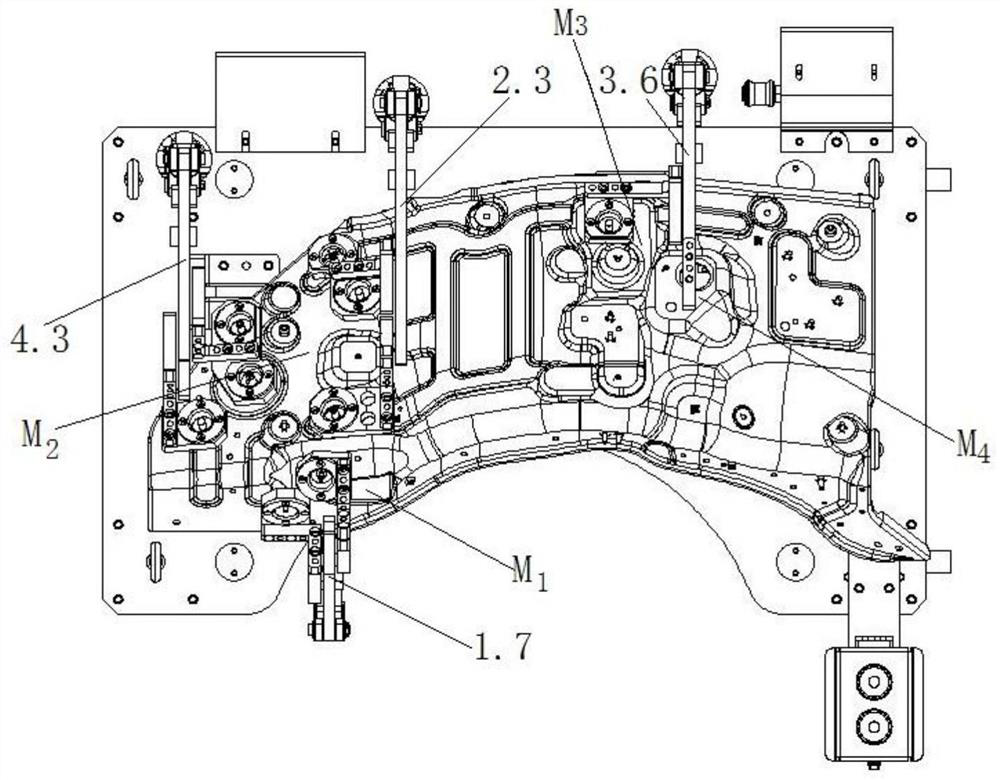

[0031] as attached figure 1 to the attached Figure 8 As shown, a positioning welding tool for the right front wheel house nail planting cover plate assembly includes a welding support platform 7 and at least one set of support clamps arranged above the welding support platform 7 along the length direction of the cover plate assembly. mechanism, the support and clamping mechanism supports and fixes the cover plate assembly, and the cover plate assembly is suspended above the welding machine support platform 7;

[0032] Some of the supporting and clamping mechanisms each include a fixed supporting mechanism and a movable clamping mechanism, and several of the fixed supporting mechanisms are arranged on the welding support platform 7, the fixed supporting mechanism supports the cover plate assembly, and some of the movable clamps The holding mechanism is arranged adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com