Automatic liquid feed feeding system

A liquid feed and feeding system technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve problems such as unbalanced livestock quality, failure to meet livestock habits, and impact on livestock health, so as to reduce labor costs and worker workload Intensity, avoiding feed waste and polluting the environment, and improving the quality of livestock breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

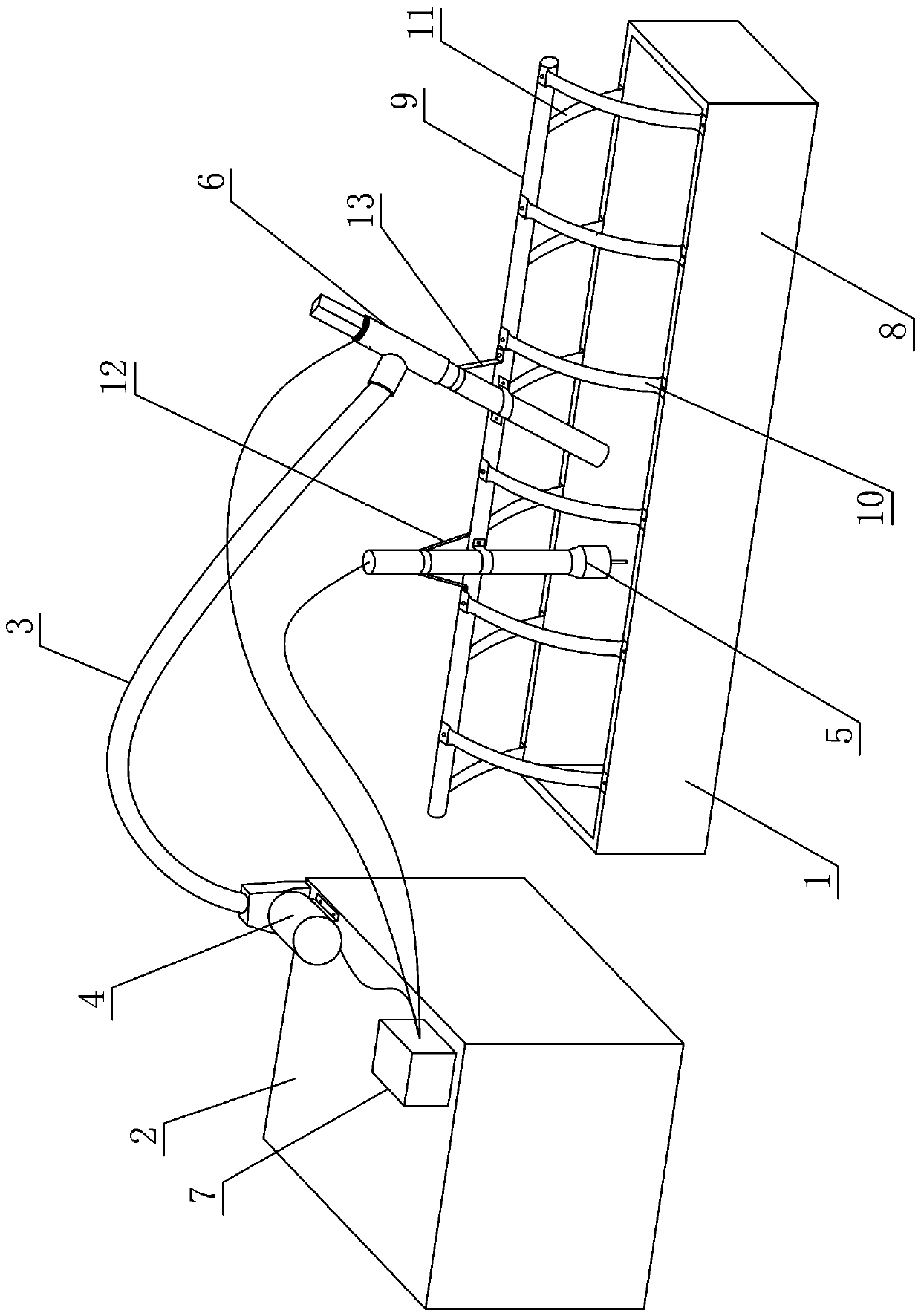

[0031] Such as figure 1 As shown, an automatic liquid feed feeding system includes a double material tank 1, a feed box 2, a delivery pipeline 3, a delivery pump 4, a liquid level sensor 5, a feeding valve 6 and a controller 7.

[0032] The double-material tank 1 is arranged between the two breeding pens and can simultaneously supply the livestock in the two breeding pens with edible feed. A conveying pipeline 3 is arranged between the feed box 2 and the double-fabric tank 1, and the conveying pipeline 3 is connected to the feed box. 2. A transfer pump 4 is provided at the junction, a feed valve 6 is provided at the junction of the transfer pipeline 3 and the double-fabric tank 1, and a liquid level sensor 5 for sensing the liquid level of the liquid feed is provided in the double-fabric tank 1. The conveying pump 4, the liquid level sensor 5, and the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com