Primary wind speed wear-resistant type measuring device

A measurement device and wind speed technology, which is applied in the direction of measuring fluid velocity by using pressure difference, can solve the problems of affecting accuracy, unstable air flow, and the problem of blockage of primary measurement components cannot be fundamentally solved, so as to prolong the service life and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

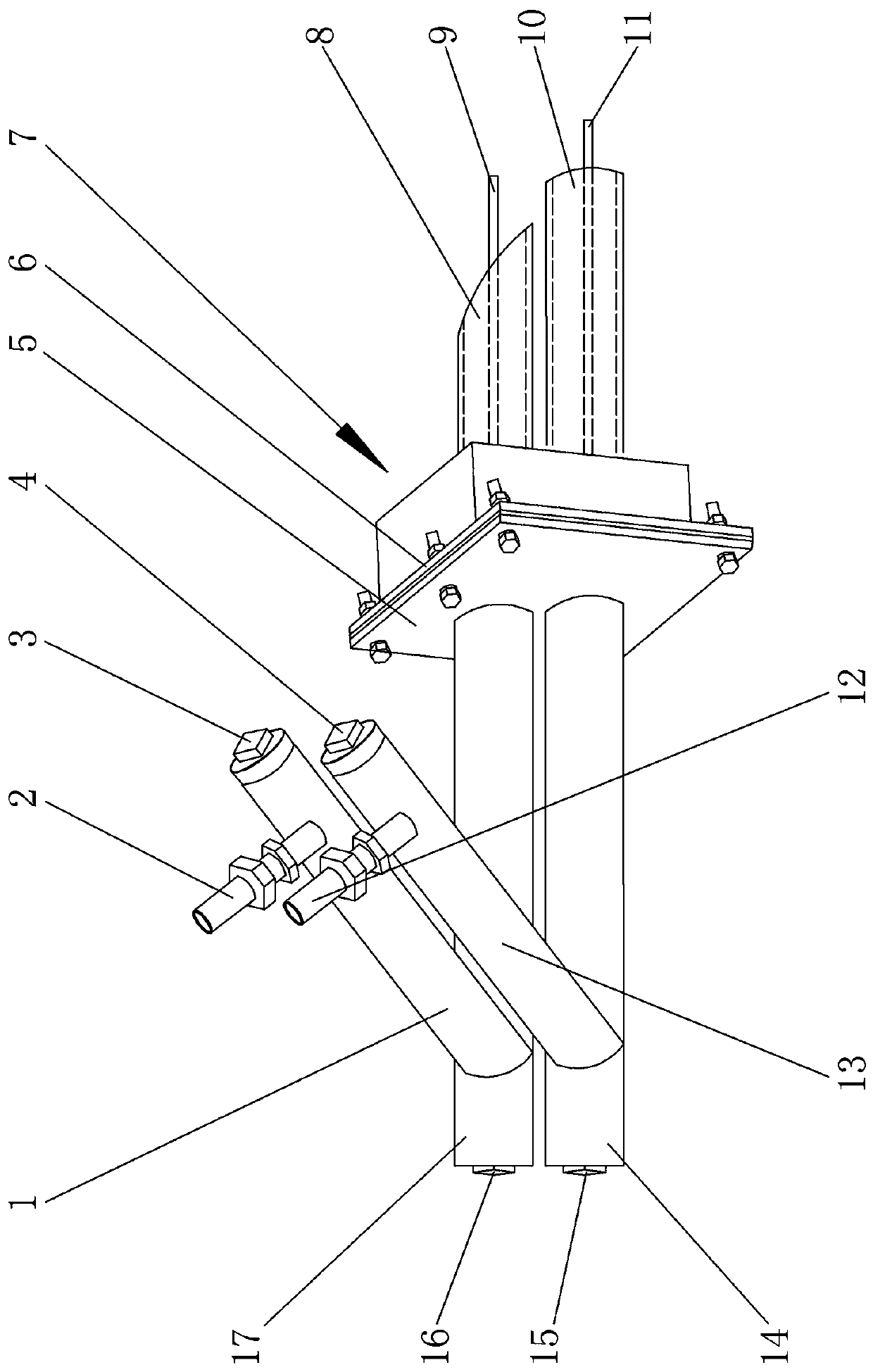

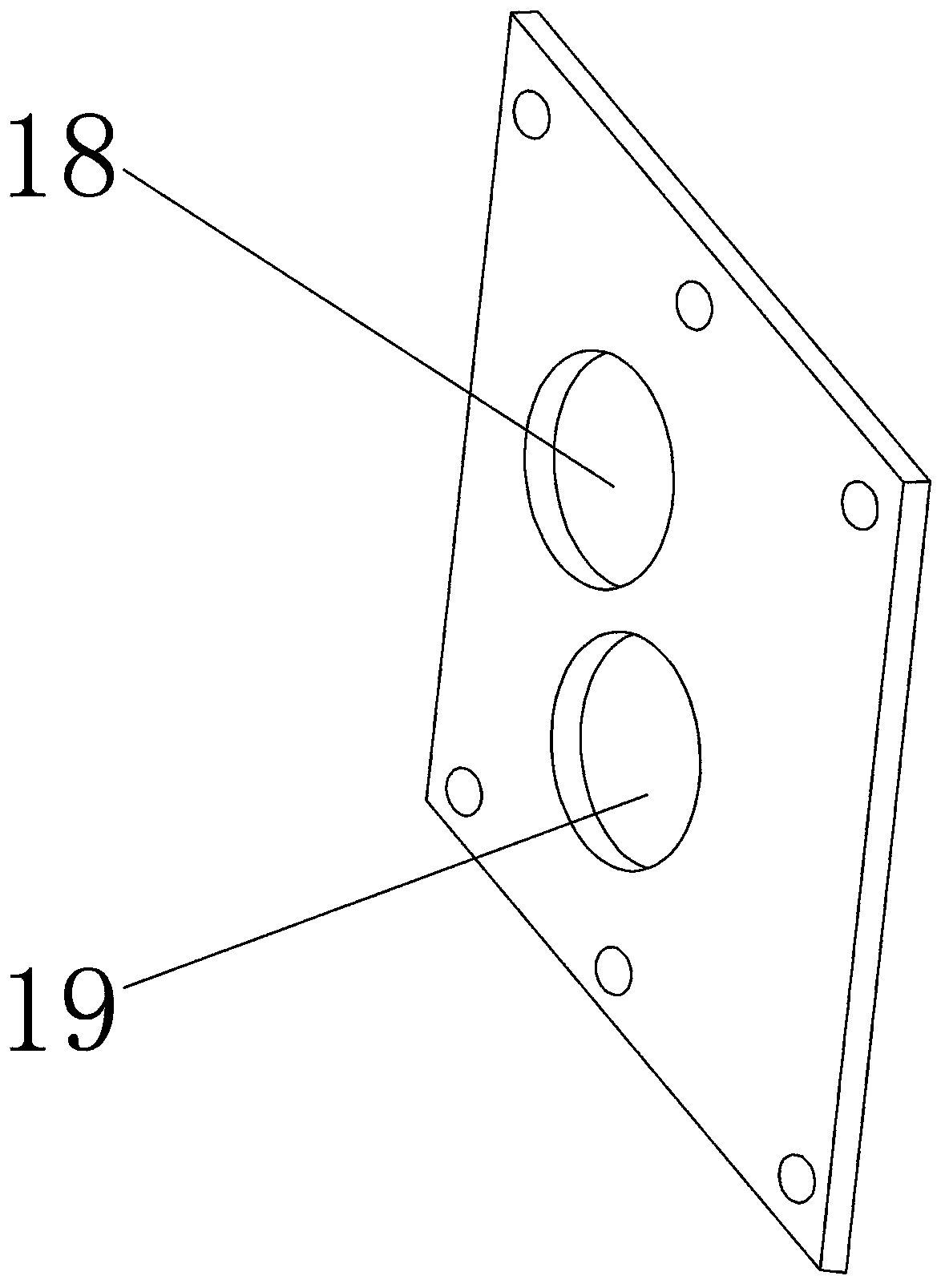

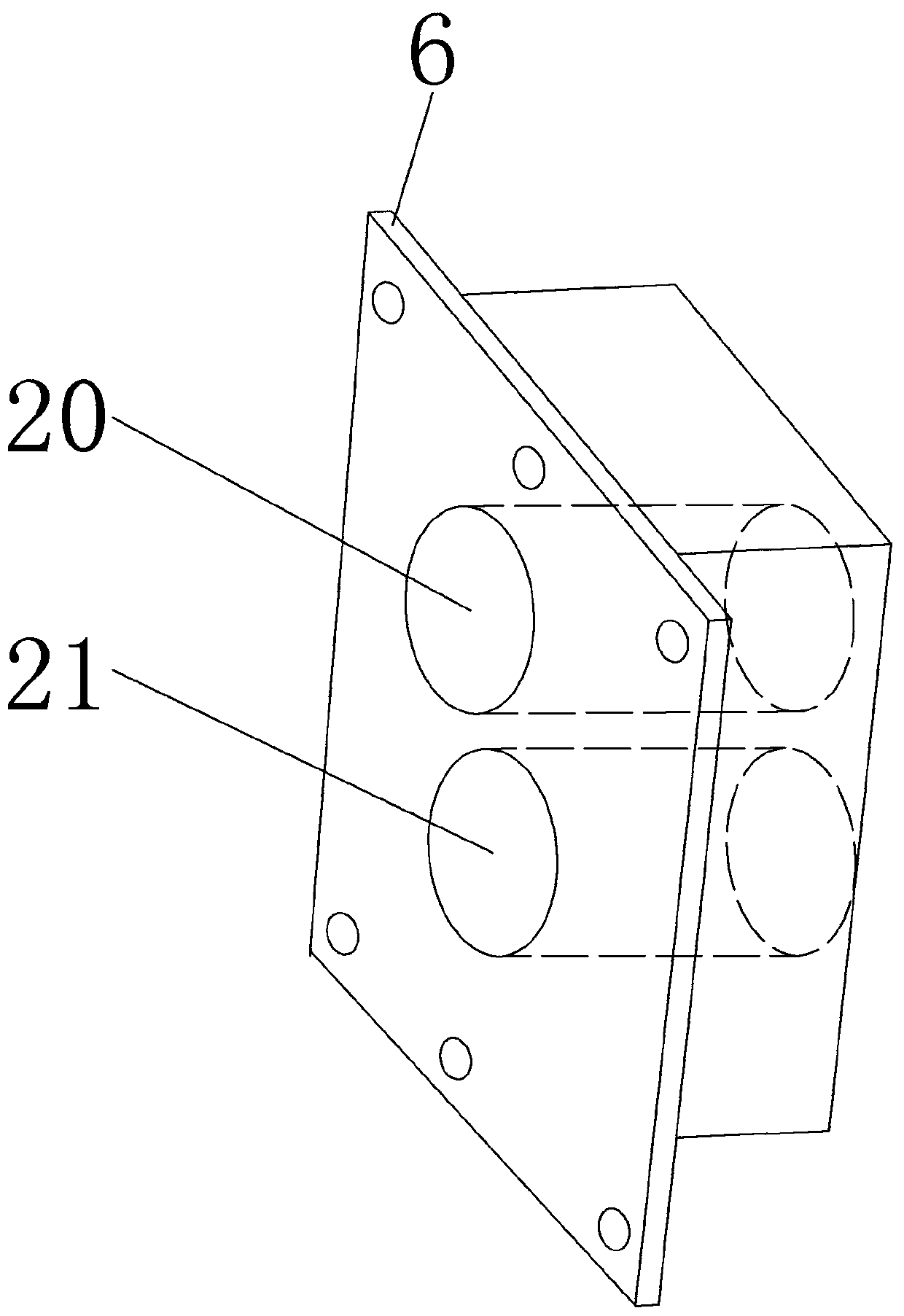

[0022] The specific embodiment of the present invention is, with reference to figure 1 , including the windward sampling pipe 17, the leeward sampling pipe 14, the secondary sedimentation chamber 1 of the windward pipe, the secondary sedimentation chamber 13 of the leeward pipe, the windward pressure joint 2, the leeward pressure joint 12, the flange 5, the fixing seat 7, the windward Probe 8, leeward probe 10, windward rapping rod 9, leeward rapping rod 11, wherein, one end of the windward sampling pipe 17 has a sealing plug 16, and the other end of the windward sampling pipe 17 is connected to the flange 5 , one end of the secondary sedimentation chamber 1 of the windward pipe communicates with the windward sampling pipe 17 at an angle of 40° at the end of the sealing plug 16, and the secondary sedimentation chamber 1 of the windward pipe is connected with the windward sampling pipe 17. There is a throttling orifice, the other end of the secondary sedimentation chamber 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com