Loading system and loading method for elevator load tests

A technology of load test and loading system, which is applied in the testing, measuring devices and instruments of machines/structural components, etc., can solve the problems of worker injury, inaccurate counterweight iron, low efficiency, etc., to avoid injury, reduce test strength, The effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

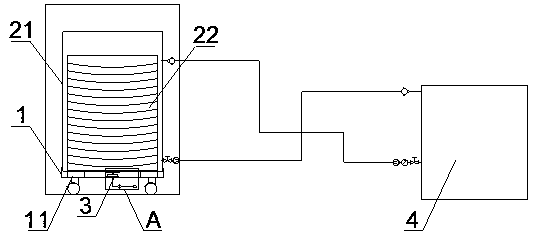

[0032] see figure 1 , a loading system for an elevator load test, including a support frame 1, a water tank, a weighing device 3 and a water supply and return device 4. The support frame 1 is provided with an elastic support 11 , and the water tank is placed on the elastic support 11 . During specific implementation, a pulley with a locking structure is provided below the support frame 1 to facilitate the movement of the support frame 1 .

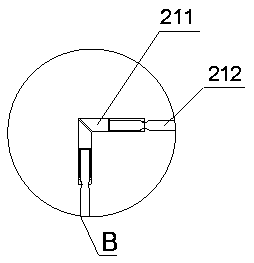

[0033] The water tank includes a limiting frame 21 open above and a telescopic water bag 22 located in the limiting frame 21 . The limit frame 21 is placed on the elastic support member 11 of the support frame 1 . see figure 2 and image 3 , during specific implementation, the limiting frame 21 includes a bottom plate, four right-angle fixing pieces 211 and four clamping plates 212 . The right-angle fixing parts 211 are fixed at the four corners of the bottom plate, and each side has a slot. The clamping slot runs through the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com