A composite method of lithium ion battery pole piece and separator and its application in battery preparation

A lithium-ion battery and separator technology, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as poor processing performance, achieve good machinability, reduce belt breakage problems, and reduce the probability of belt breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

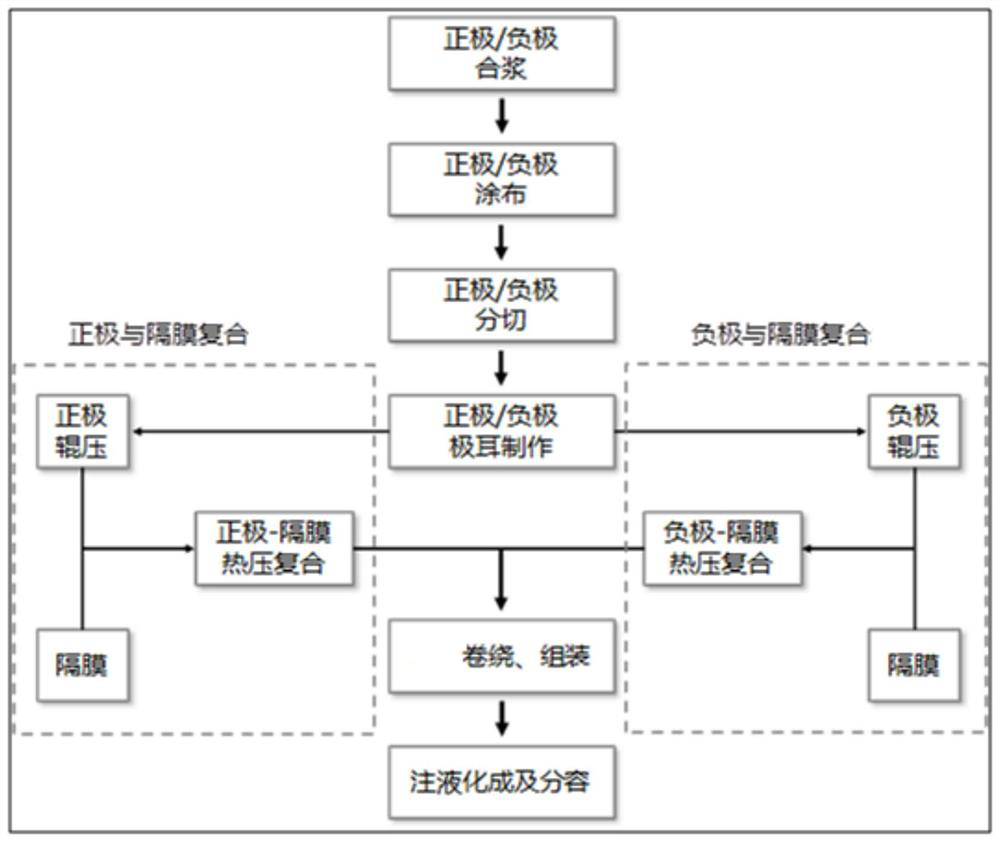

[0027] In this example, the preparation method and steps of the wound square aluminum shell 20100140 type battery are taken as an example to illustrate the application of the composite method of the lithium ion battery pole piece and the separator of the present invention in the battery preparation. The process flow chart of lithium-ion battery preparation is as follows: figure 1 shown.

[0028] (1) Positive / negative electrode slurry:

[0029] Positive slurry: Lithium iron phosphate (10kg), SP, composite conductive agent and PVDF are dissolved and dispersed in a certain amount of NMP according to the ratio of 96:0.5:1:2.5 to obtain a solid content of about 55% and a viscosity of 4000mpa. s positive electrode slurry; negative electrode slurry: artificial graphite (8kg), SP, CMC and SBR are dissolved and dispersed in a certain amount of water according to the ratio of 96:0.8:1.2:2 to obtain a solid content of about 45-50%, Anode slurry with viscosity of 2000-3000mpa.s;

[003...

Embodiment 2

[0046] This example further illustrates the application of the composite method of a lithium ion battery pole piece and a separator according to the present invention in battery preparation by taking the preparation method and steps of a wound cylindrical aluminum shell 32131 battery as an example.

[0047] (1) Positive / negative electrode slurry:

[0048]Positive slurry: Lithium iron phosphate (10kg), SP, composite conductive agent and PVDF are dissolved and dispersed in a certain amount of NMP according to the ratio of 96:0.8:1:2.2 to obtain a solid content of about 55% and a viscosity of 4000mpa. s positive electrode slurry; negative electrode slurry: artificial graphite (8kg), SP, CMC and SBR are dissolved and dispersed in a certain amount of water according to the ratio of 95.5:1:1.3:2.2 to obtain a solid content of about 45-50%, Anode slurry with viscosity of 2000-3000mpa.s;

[0049] (2) Positive / negative electrode coating:

[0050] Positive electrode coating: The curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com