Assembly type finish hanging plate system component

A prefabricated and decorative technology, applied in the direction of connecting components, building structures, pins, etc., can solve the problems of wall damage, difficult to control and adjust the position of the board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

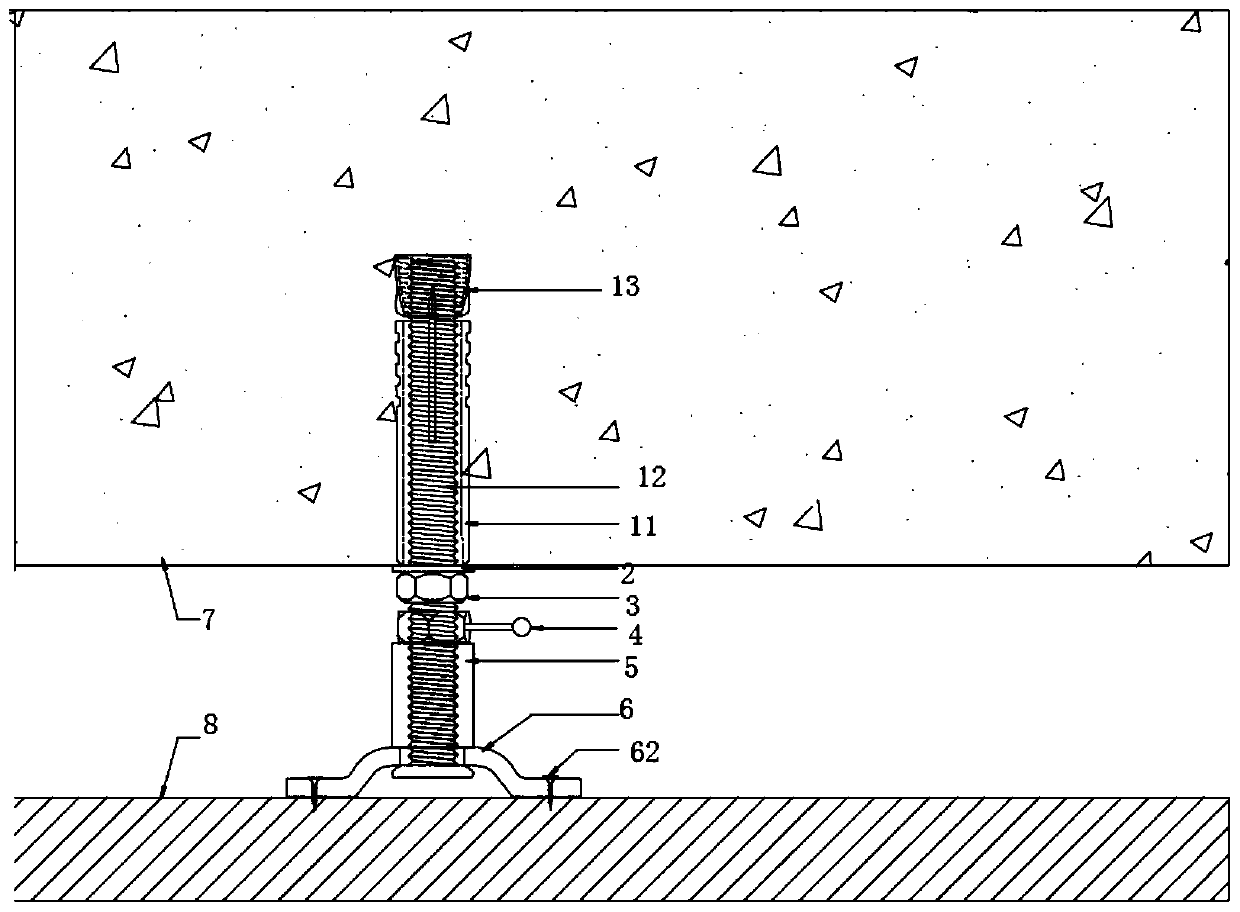

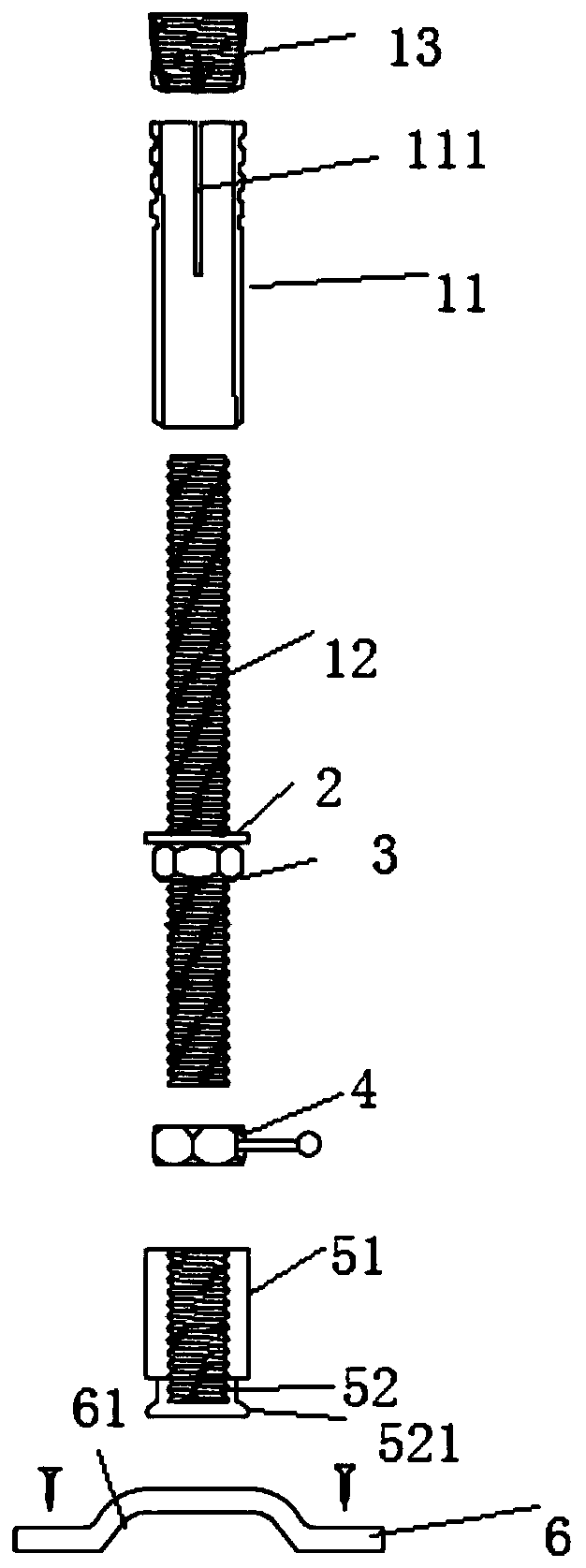

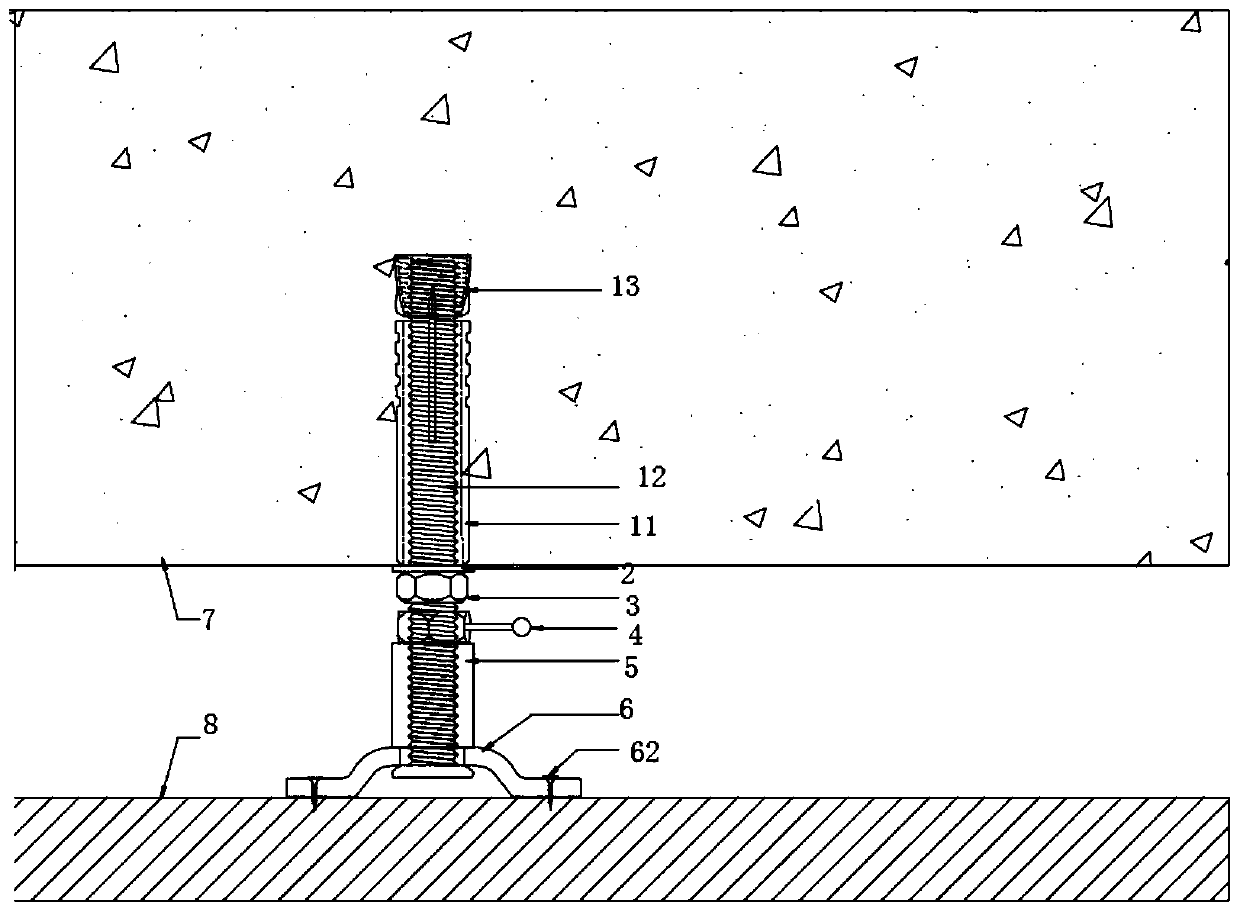

[0032] figure 1 It is a schematic diagram of a component of a prefabricated veneer siding system of the present invention; figure 2 It is an exploded diagram of a component of a prefabricated veneer siding system of the present invention.

[0033] See Figure 1 to Figure 2 As shown, a preferred embodiment is shown, a component of the prefabricated veneer siding system, including

[0034] Fastener, fastener comprises expansion pipe 11, screw rod 12 and wedge-shaped head 13; The outer surface of the front portion of expansion pipe 11 is provided with some axial slits 111; One end of bolt 12 is inserted in the expansion pipe 11, and this end It protrudes from the front end of the wedge-shaped head 13 , and the protruding part of the bolt 12 is covered with the wedge-shaped head 13 .

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com