Automobile seat buckle sealing strip

A technology for car seats and sealing strips, which is applied to vehicle seats, seat covers, vehicle parts, etc., can solve problems such as increased damage probability, damaged connection holes, damaged thickened sections, etc., and achieves reliable connection, smooth exterior, and edges. Smooth transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

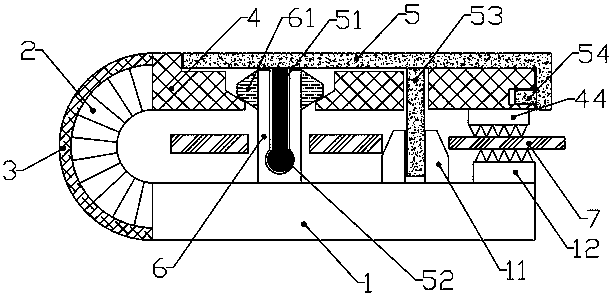

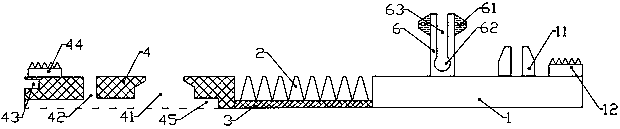

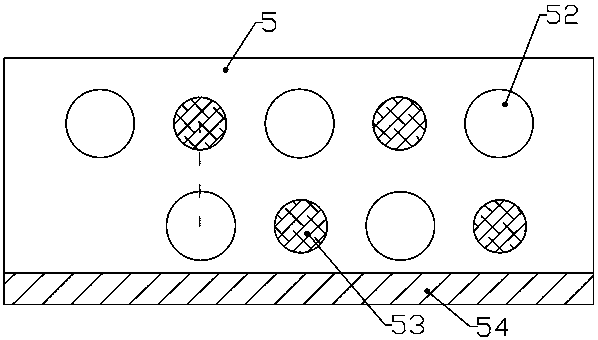

[0026] Such as figure 1 and figure 2 As shown: this embodiment discloses a buckle sealing strip for a car seat, which includes a base plate 1, an upper cover 4 and a locking cover plate 5. The outer surface of the base plate 1 is provided with two rows of connecting rod assemblies, and the connecting rod assemblies include alternately arranged The connecting rod 6 and the hollow column 11, the upper edge of the connecting rod 6 is provided with a thickened section 61, the middle is provided with a cut groove 63, and the lower end of the cut groove 63 is provided with a spherical end 62; Connecting hole 1 41 of connecting rod 6, locking cover plate 5 is provided with locking column 1 51 and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com