A walking motor speed control system with both manual and automatic gear shifting functions

A walking motor and speed control technology, which is applied to servo motors, servo motor components, fluid pressure actuators, etc., can solve problems such as potential safety hazards and crawler mechanical vibration, and achieve low maintenance difficulty, low processing cost, and internal flow. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

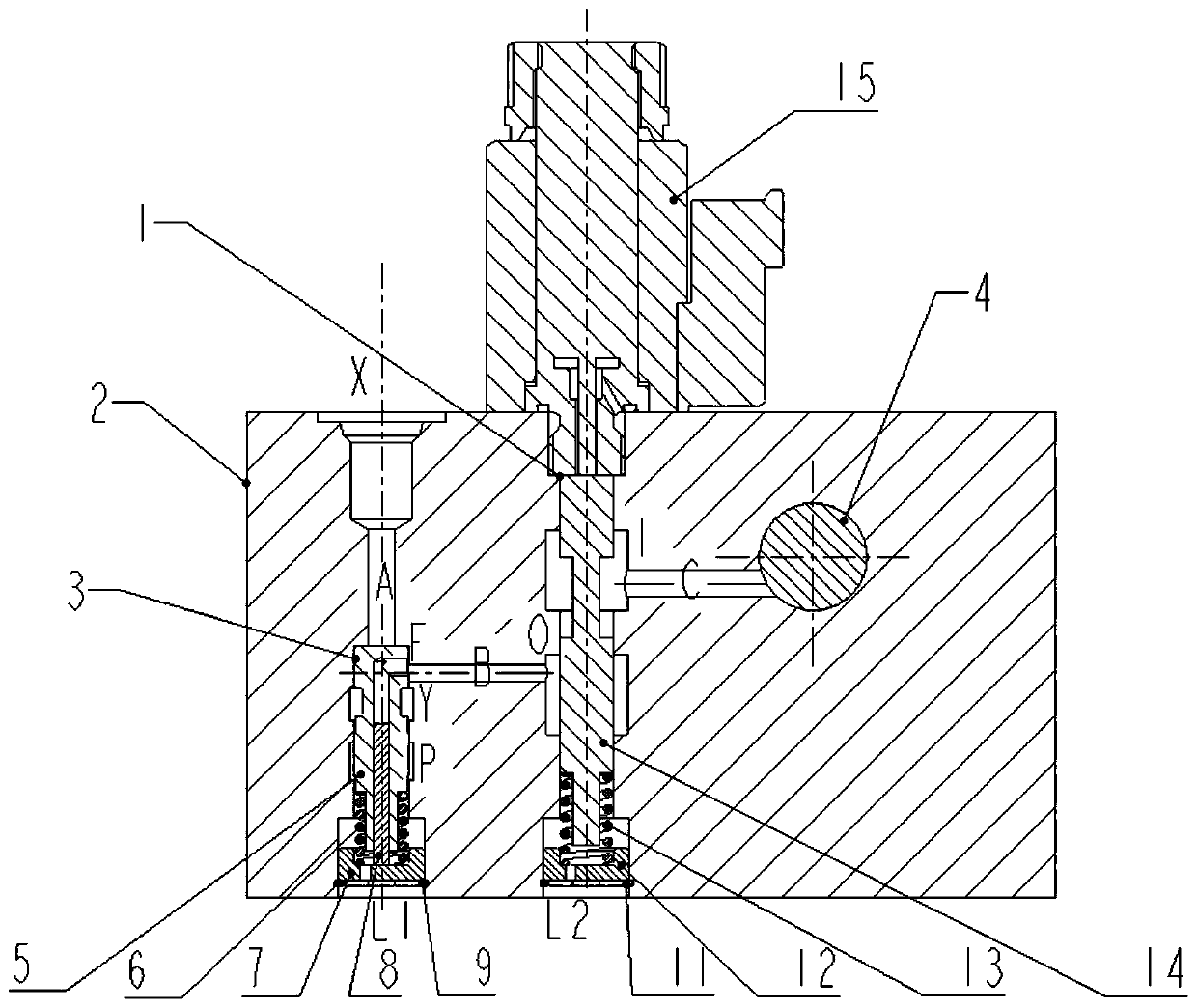

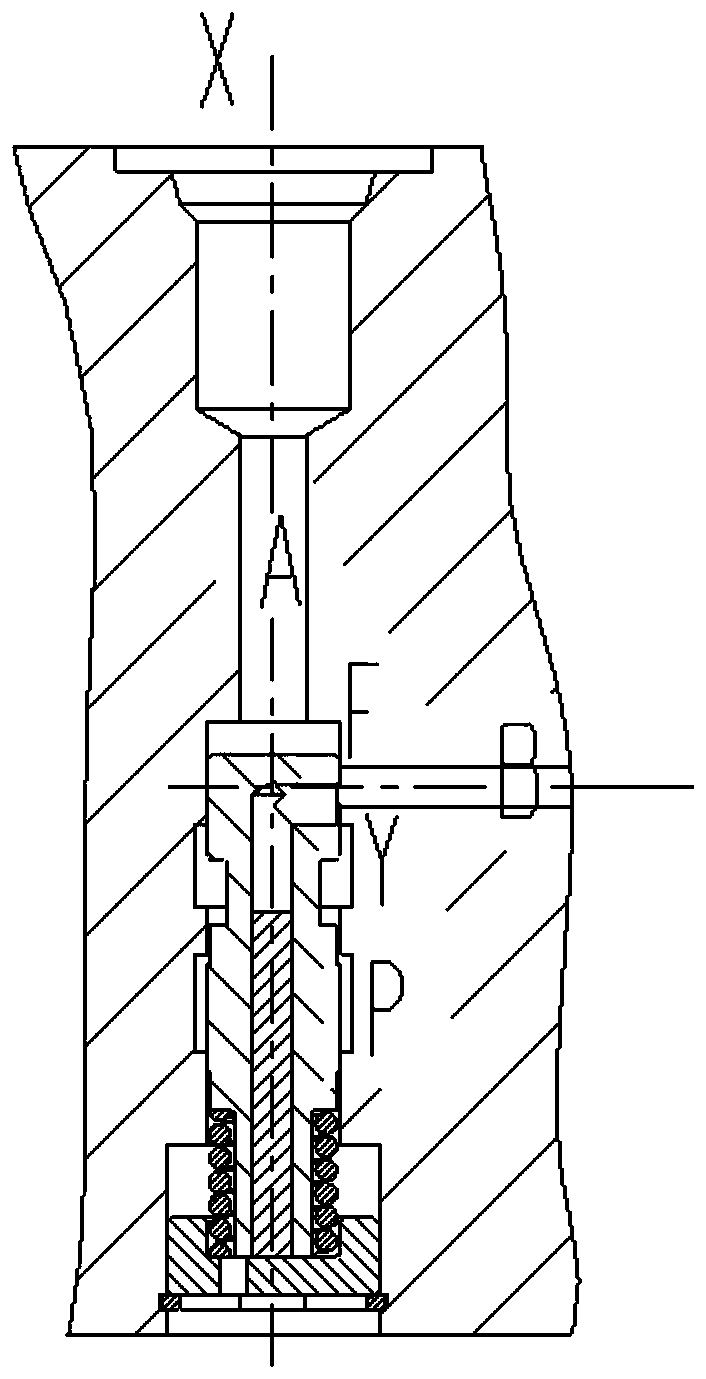

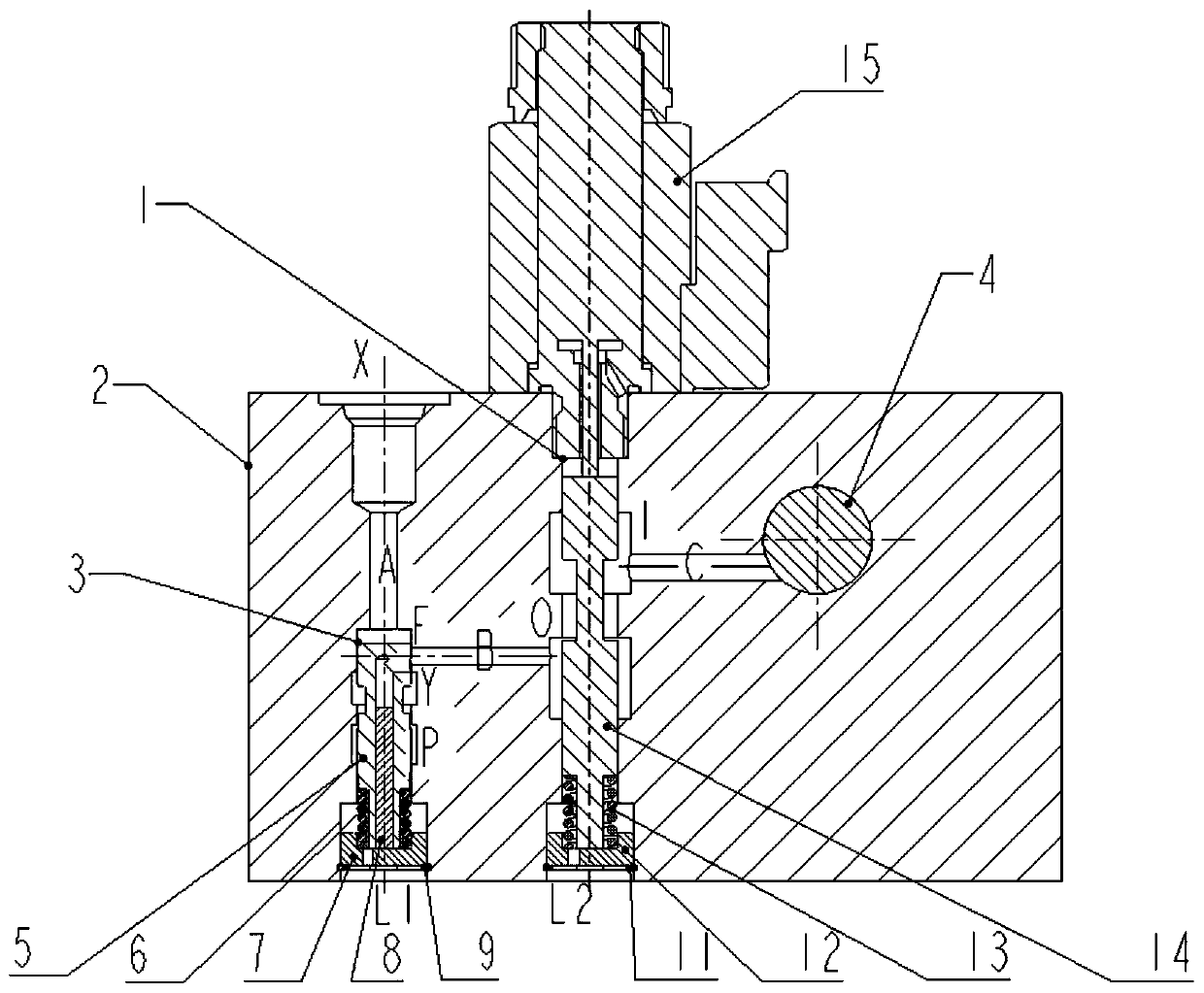

[0039] The invention patent adopts figure 1 with figure 2The structure shown includes motor end cover 2, shift valve 3, manual / automatic switching valve 1, balance valve 4, pilot oil circuit A, oil circuit B and oil circuit C. The shift valve 3 and the manual / automatic switch valve 1 are built inside the motor end cover 2, wherein the shift valve 3 is composed of a valve core 5, a return spring 6, a valve seat 7, a valve stem 8, and a retaining ring 9. One end is inserted into the valve seat 7 and can move along the valve seat 7. The return spring 6 is sleeved on the valve core 5, and is clamped by the shoulder on the valve core 5 and the valve seat 7. There is a vertical intersecting hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com