Gantry manipulator sorting device

A sorting device and manipulator technology, applied in sorting and other directions, can solve problems such as small flexibility, single mode, poor adaptability to working conditions and environment, and achieve the effect of improving flexibility, improving flexibility, and strengthening secondary development functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

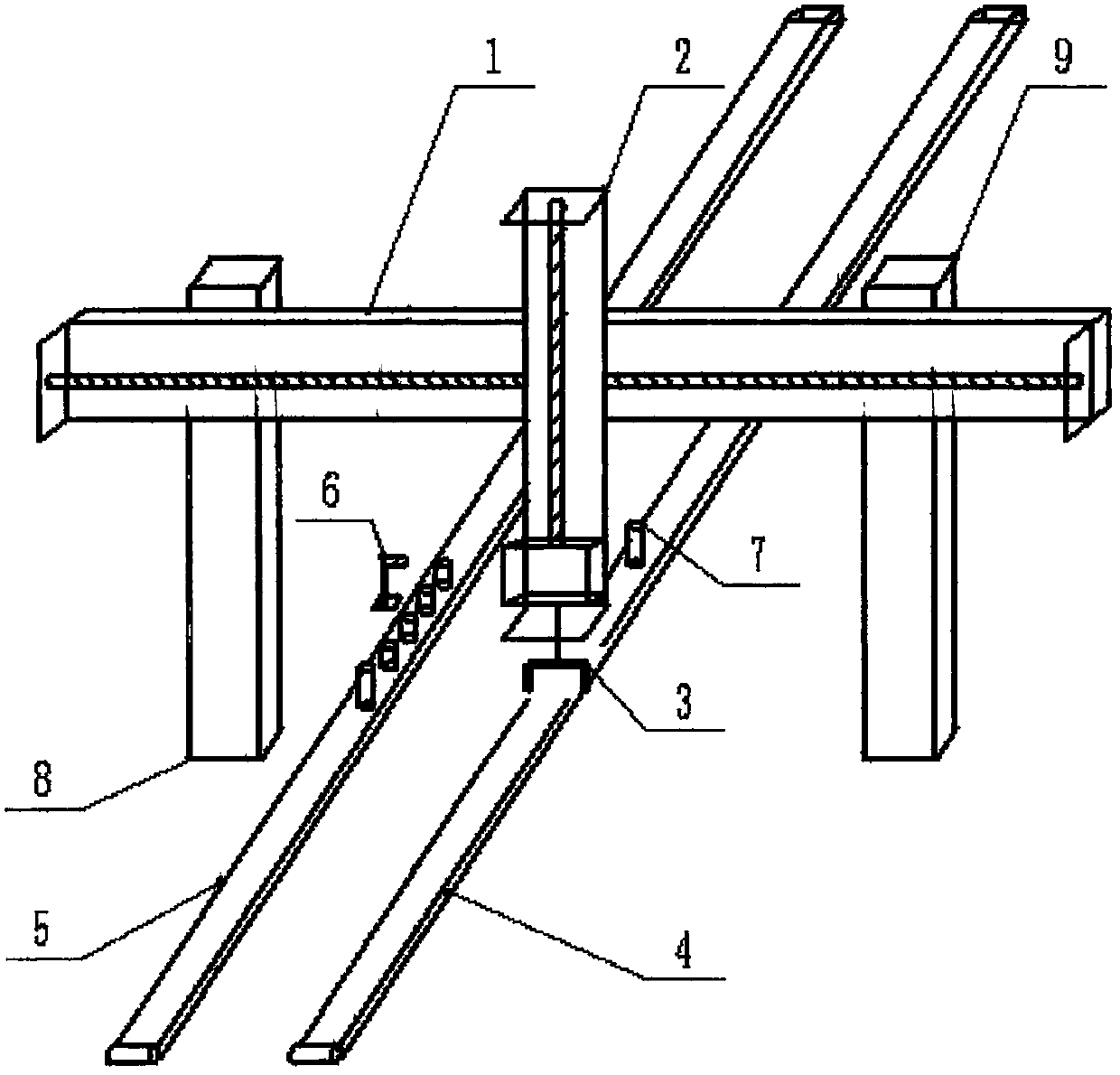

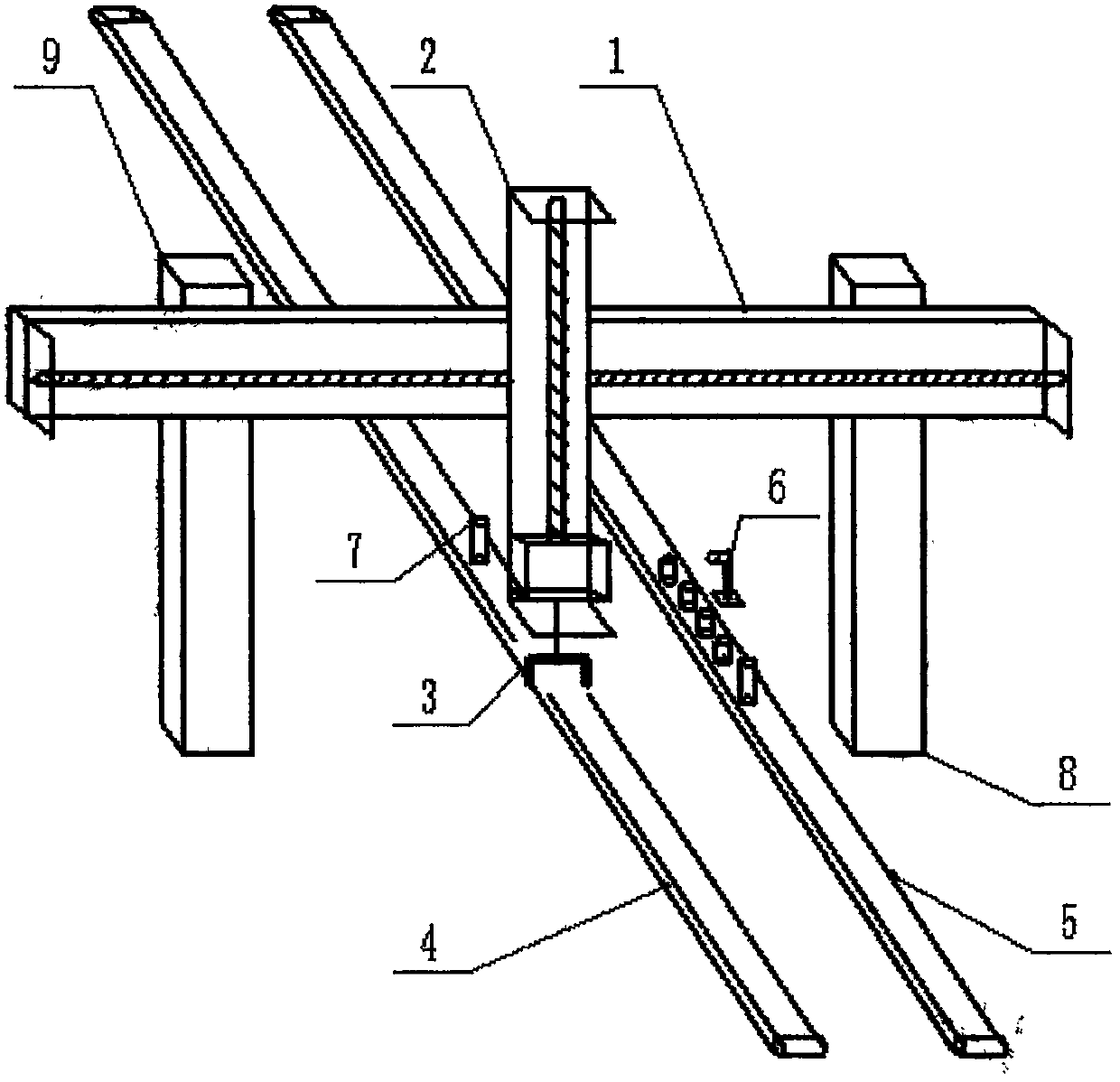

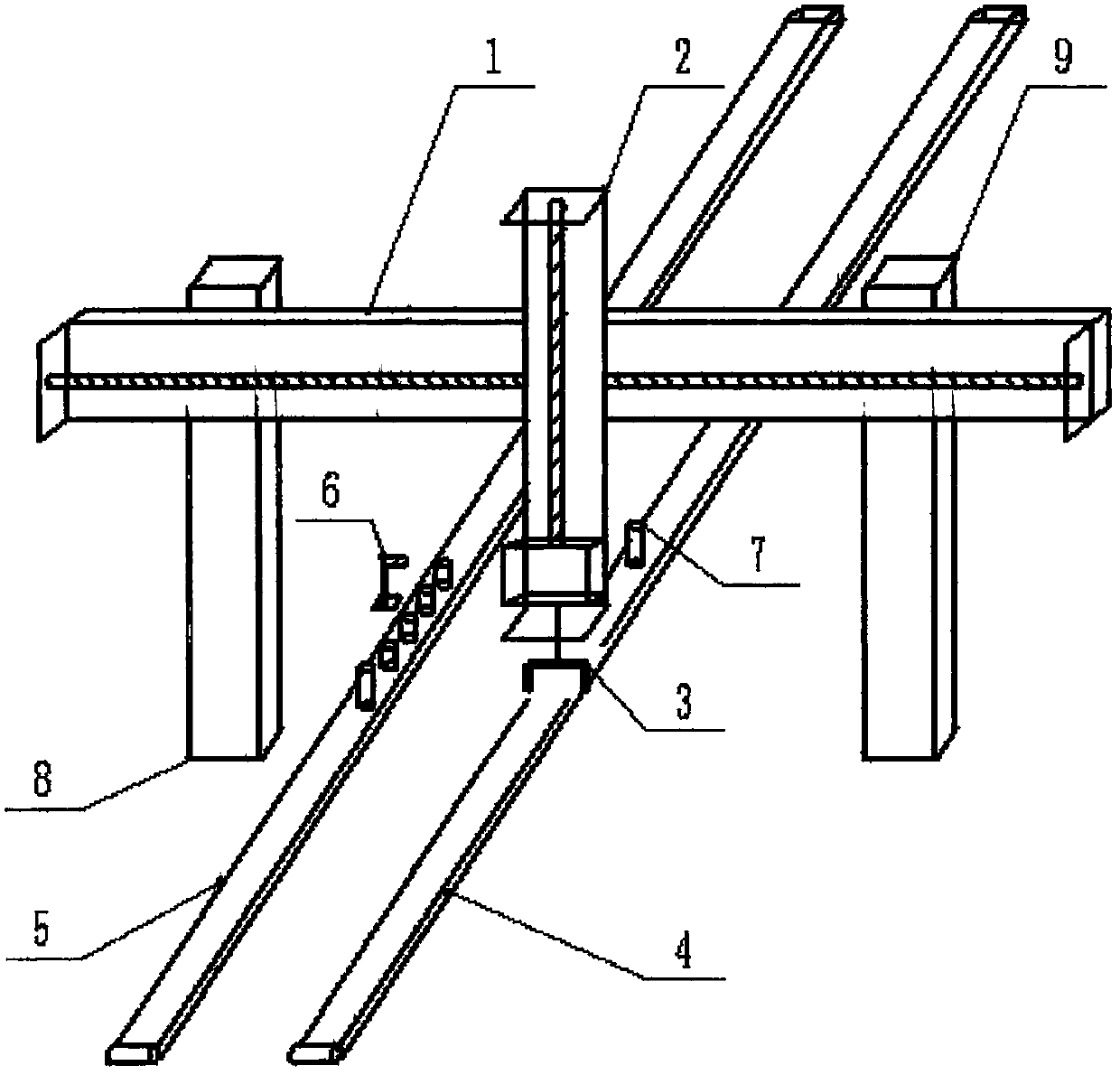

[0010] refer to figure 1 , as shown in 2, a flexible loading and unloading gantry manipulator includes: a gantry type unloading manipulator, the manipulator consists of an X-axis guide rail 1, a Z-axis ball screw 2, an end gripper 3, and aluminum support rods 8, 9 The material conveyor belts 4 and 5 are responsible for transporting materials; the sorting and identification device is responsible for the sensor 6; the target material 7 is mixed in the material pile, and the PLC control cabinet is responsible for controlling the loading and unloading manipulator, the conveyor belt of the transporting device and the operation of the sorting and identification device.

[0011] The beneficial effects of the present invention are: the present invention can realize material loading, transportation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com