Roof block filling hydraulic support and using method thereof

A technology of hydraulic supports and blocks, which is applied to mine roof supports, fillings, earthwork drilling and mining, etc. It can solve the problems of high labor intensity, difficulty in following machine operations, and low filling efficiency, and achieves obvious rock formation control effects and easy operation. Convenience, effect of reducing handling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

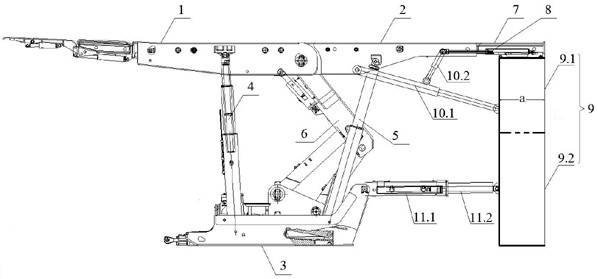

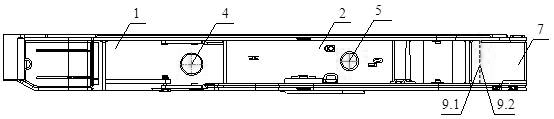

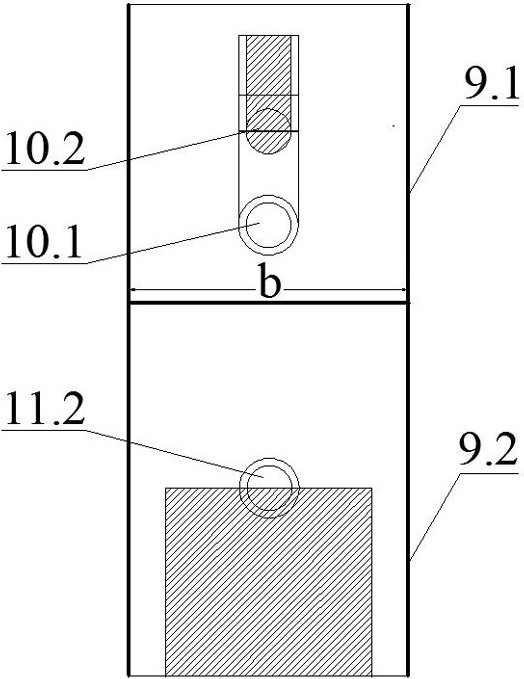

[0025] This embodiment provides a jacking block filling hydraulic support, including a support body; the support body includes a front roof beam 1, a rear roof beam 2 hinged with the front roof beam, and a The base 3, the front column 4 whose two ends are respectively hinged on the front roof beam 1 and the base 3, the rear column 5 whose two ends are respectively hinged on the rear roof beam 2 and the base 3, and the front column 4 and the rear column 5 are arranged between The four-bar linkage mechanism 6 is equipped with a telescopic beam 7 at the tail of the rear top beam 2, and the telescopic beam jack 8 inside the telescopic beam 7 protrudes from the telescopic beam 7 to connect with the rear top beam 2, and a filling and pouring mold is provided under the telescopic beam 7 9. The filling and pouring mold 9 includes an upper mold 9.1 located below the telescopic beam 7 and a lower mold 9.2 slidingly connected with the upper mold 9.1; both the upper mold 9.1 and the lower ...

Embodiment 2

[0034] This embodiment provides a method for using the roof block filling hydraulic support described in Embodiment 1, which includes the following steps:

[0035] S1, after the cut hole layout of the working face is completed, install the roof block filling hydraulic support, put the filling casting mold 9 close to the coal wall, and the telescopic beam 7 is in the retracted state (that is, the telescopic beam 7 is retracted into the top beam 2 at this time) , the mold height adjustment device swings upwards to drive the upper mold 9.1 to forcibly connect with the top plate to form a block pouring space;

[0036] S2, conveying the pouring material into the filling pouring mold 9 through the pouring pipeline, and performing the block pouring operation;

[0037] S3, after the blocks in the filling and pouring mold 9 are solidified to reach the preset strength, the mold pushing device pulls out the filling and pouring mold 9, moves and demoulds, and controls the moving step of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com