Preparation method and application of iron oxide@biomass carbon fiber@pda-pvdf photo-Fenton composite beads

A biomass carbon and iron oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of poor catalyst stability, loss of active metals, and difficult operation. and other problems, to achieve the effects of improving stability, degrading organic pollutants, and simple and convenient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

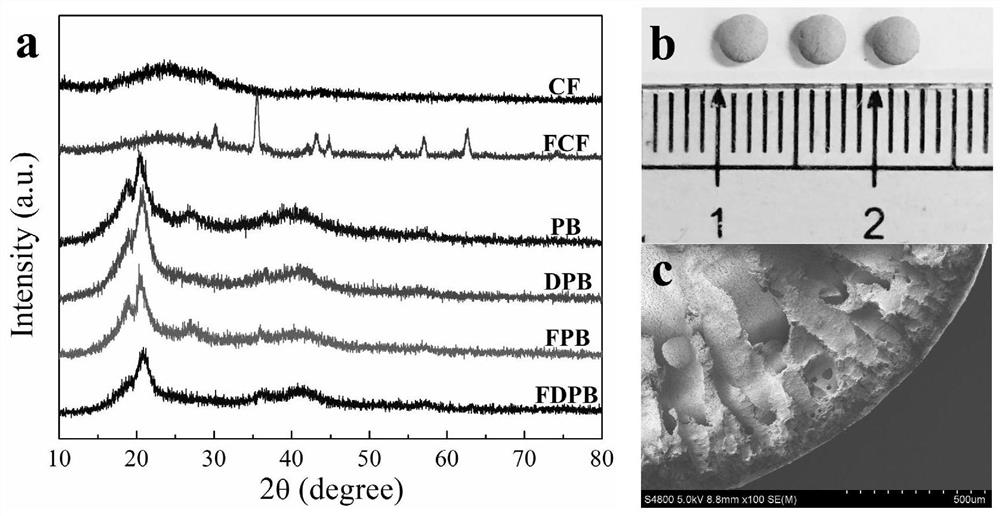

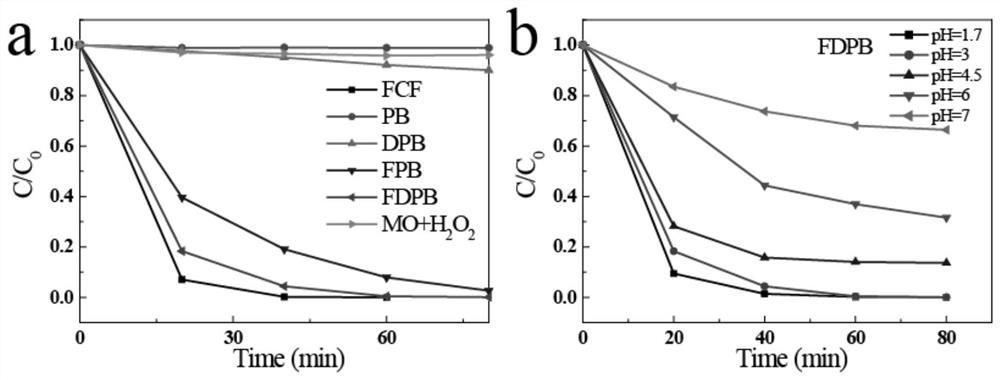

[0029] (1) Preparation of FCF composite photo-Fenton catalyst

[0030] Weigh the dried cattail in a crucible, transfer it to a tube furnace, and calcinate it at 800°C for 3h with a heating rate of 5°C / min, take it out after natural cooling, and obtain CF for use; take 0.3g CF and 1mmol FeSO 4 ·7H 2 O was dispersed in 35 mL of deionized water and shaken at room temperature for 12 h; after drying, the obtained solid was transferred to a tube furnace and calcined at 850 °C for 3 h to obtain the FCF composite photo-Fenton catalyst.

[0031] (2) Preparation of FCF@pDA-PVDF photo-Fenton composite beads

[0032] First, disperse 0.6g dopamine powder and 6g PVDF powder in 300mL Tris-HCl buffer solution, then add 10mL ethanol, and adjust the pH of the solution to 8.5, and stir the mixture vigorously for 6h to complete the self-polymerization of polydopamine on the surface of PVDF powder. Finally, filter, wash and dry to obtain pDA-PVDF powder. Weigh 0.05g of FCF, 2g of pDA-PVDF powde...

Embodiment 2

[0034] Under the condition that other conditions are kept constant, a comparative test is established as follows: when preparing FCF composite photo-Fenton catalyst, take 0.3gCF and 1mmol FeSO 4 ·7H 2 O was dispersed in 35 mL deionized water and shaken at room temperature for 12 h; after drying, the obtained solid was transferred to a tube furnace, and the FCF composite photo-Fenton catalyst was obtained by changing the calcination temperature to 550 °C and calcining for 3 h.

Embodiment 3

[0036] Under the condition that other conditions are kept unchanged, the comparative experiment is established as follows: when making FCF composite photo-Fenton catalyst, by changing CF and FeSO 4 ·7H 2 O ratio to examine the loading of iron oxides, take 0.3g CF and 3mmol FeSO 4 ·7H 2 O was dispersed in 35 mL deionized water, shaken at room temperature for 12 h; after drying, it was calcined at 850 °C for 3 h to obtain the FCF composite photo-Fenton catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com