Steam exhaust structure and steam oven adopting same

A technology of a steam oven and a drainage structure, which is applied in the field of steam ovens, can solve problems such as affecting the taste of food, rising temperature, and inconsistent heating of food up and down, so as to reduce the time required for cooling, improve the environment for steaming and roasting, and improve the quality of steaming and roasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, only one exhaust port is closed for the automatic switching closing structure.

[0067] The steam exhaust port includes a first steam exhaust port 64 and a second steam exhaust port 63; the first steam exhaust port 64 and the second steam exhaust port 63 are respectively communicated with the accommodating cavity 2; the automatic switching closing unit Used to close or open the first exhaust port.

[0068] In order to improve the energy utilization rate of the high-temperature steam, the first steam exhaust port 64 communicates with the gas outlet 21 at the top of the housing chamber; the second steam exhaust port 63 communicates with the gas outlet 22 at the bottom of the housing chamber.

[0069]Under normal conditions, the automatic switching closing unit closes the first steam exhaust port. At this time, the high-temperature steam is discharged from the air outlet 22 at the bottom of the storage chamber, which effectively prolongs the residence t...

Embodiment 2

[0080] In this embodiment, the automatic switching closing unit can simultaneously close or open the first and second exhaust ports.

[0081] The steam exhaust port includes a first steam exhaust port 64 and a second steam exhaust port 63 ; the first steam exhaust port 64 and the second steam exhaust port 63 communicate with the accommodating chamber 2 respectively.

[0082] The automatic switching closing unit can realize three functions:

[0083] (1) Close the first and second exhaust outlets at the same time;

[0084] (2) Open the second exhaust port and close the first exhaust port;

[0085] (3) Open the first and second exhaust ports at the same time.

[0086] Here, the structural form of the automatic switching closing unit can adopt the method in the first embodiment, so no detailed description will be given.

Embodiment 3

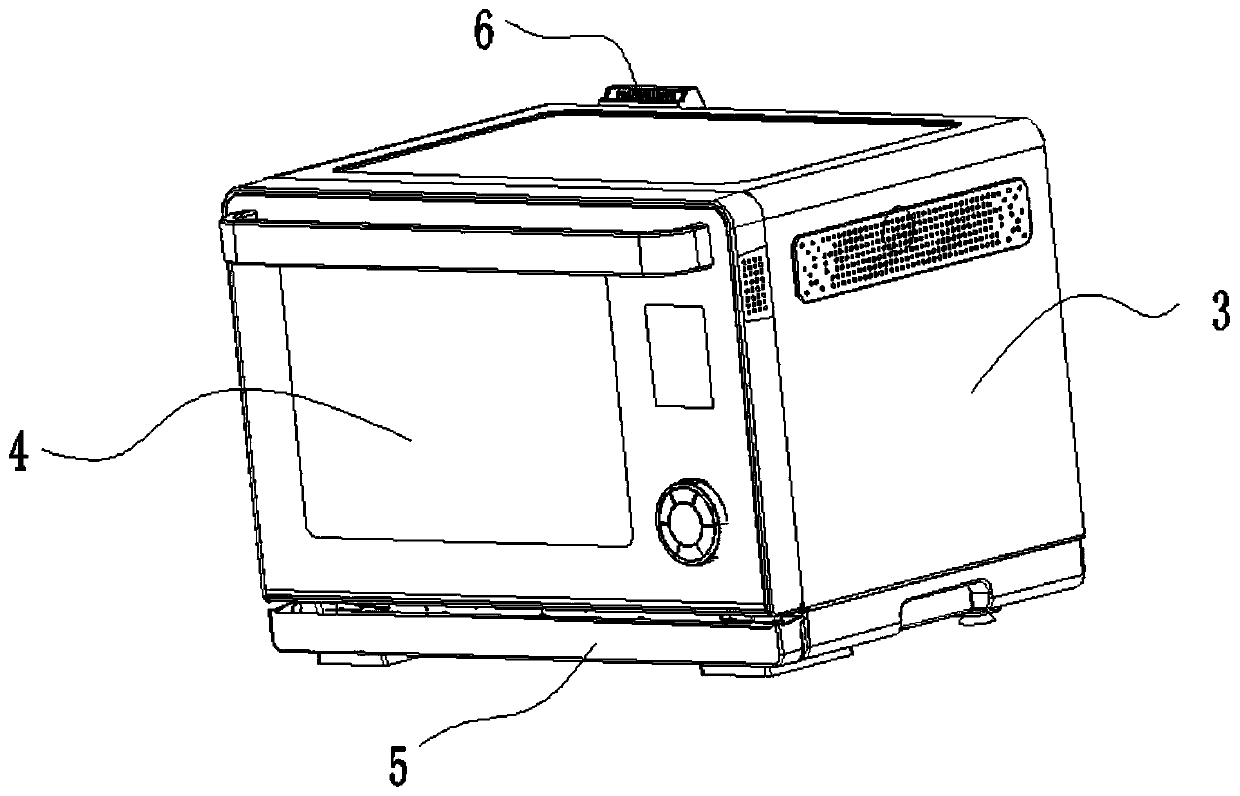

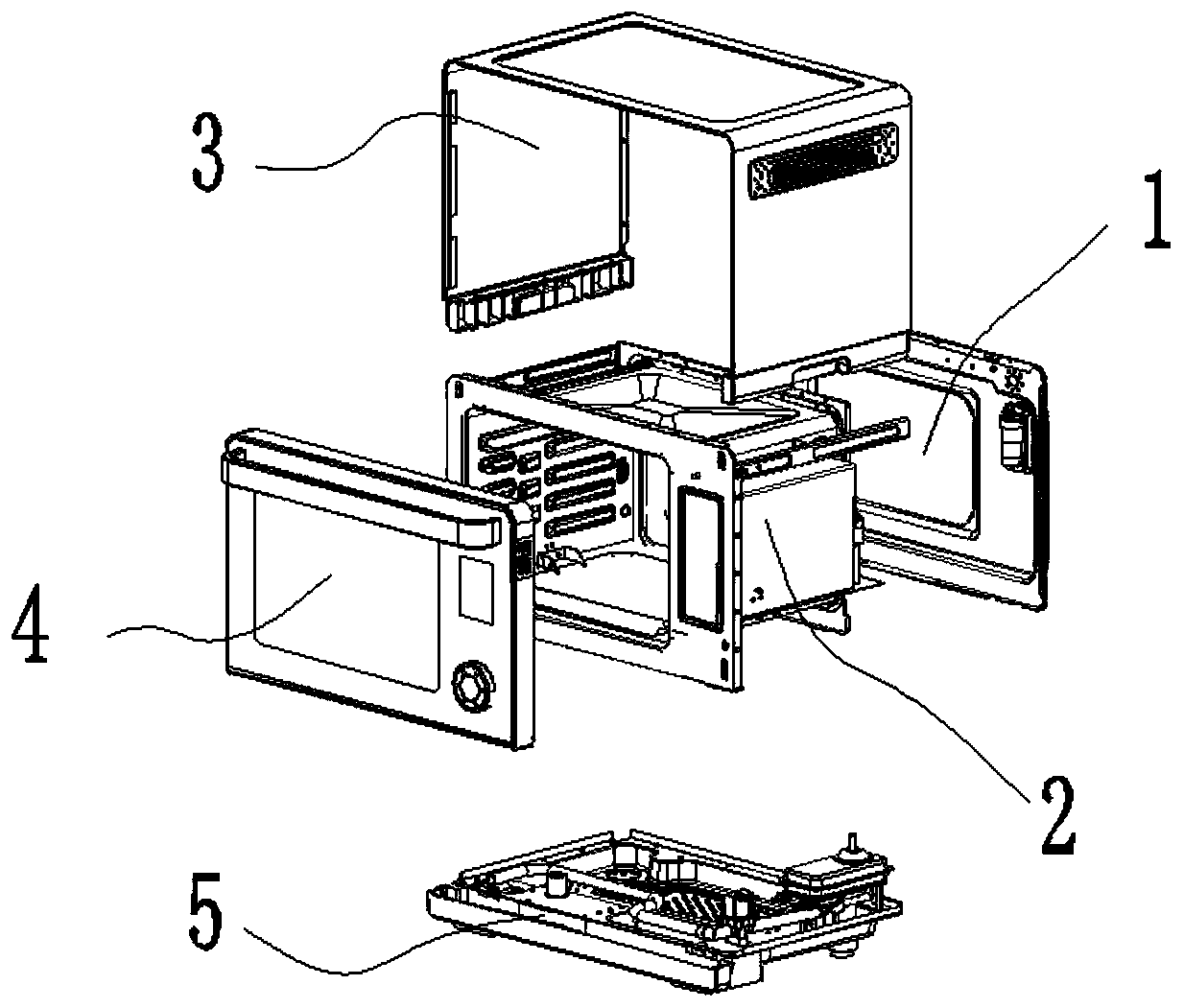

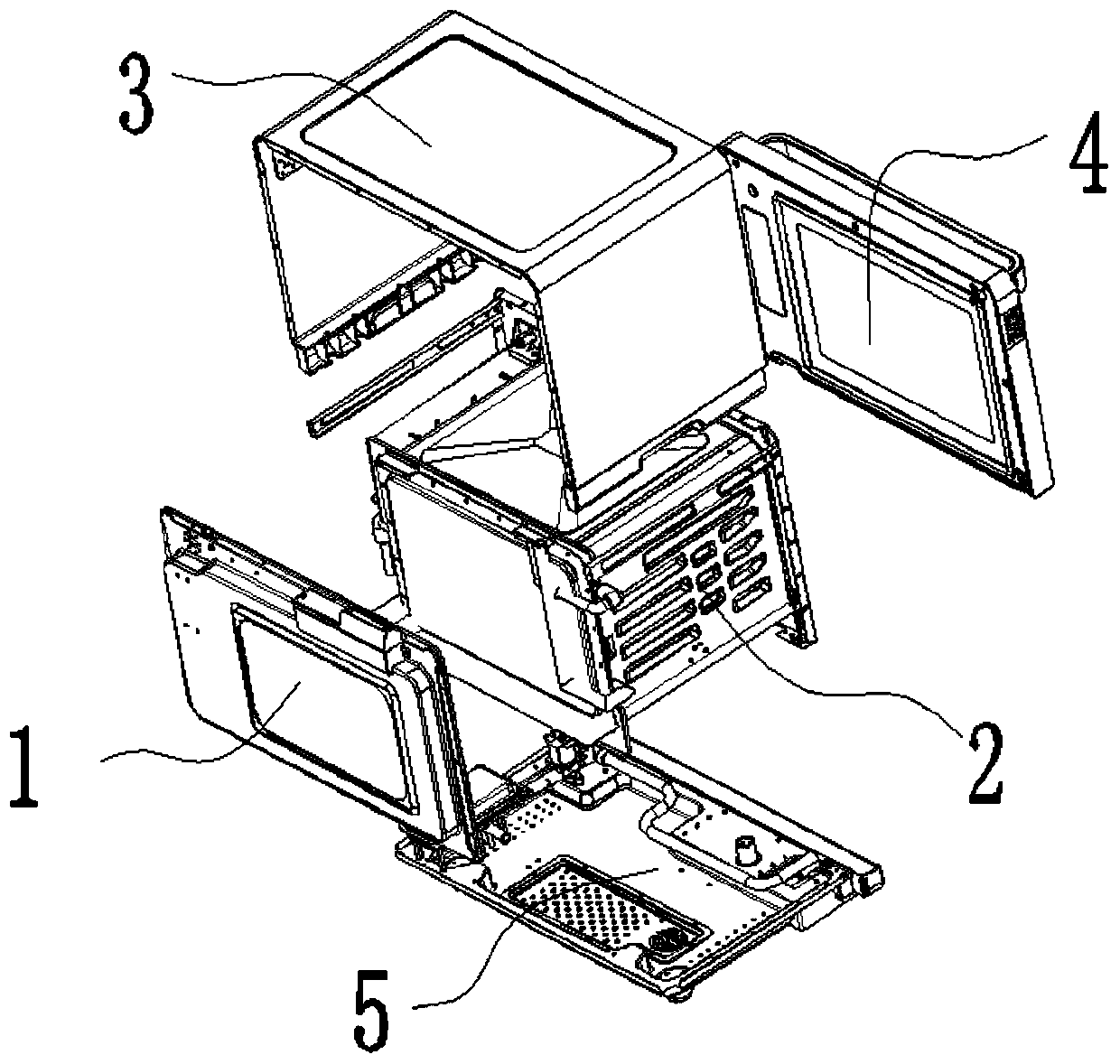

[0088] A steam oven adopts the steam exhaust structure in Embodiment 1 or Embodiment 2.

[0089] It includes a door body 4, an accommodating chamber 2, a housing 3, a rear cover 1 and a water receiving tray 5; the water receiving tray 5 includes an accommodating chamber water receiving part 52, an external water receiving part 53 and a connecting part, and the accommodating chamber is connected to The water part 52 is sealed and communicated with the drainage structure of the storage chamber; the water receiving part of the storage chamber is connected with the external water part through the communication part; the communication part includes a steam leakage prevention structure.

[0090] Wherein, the water receiving part 52 of the housing chamber is a sealed space, that is to say, the water receiving part 52 of the housing chamber is sealed with the outside world except that the water receiving part 52 of the housing chamber is the same as the drainage structure and the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com