Linear-shear piezoelectric ceramic cooperatively driven step-rotation actuating device and method

A piezoelectric ceramic, rotary actuation technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of small actuation stroke, piezoelectric ceramic actuation It is difficult for the controller to realize the torque output of large stroke and large rotation angle, so as to achieve the effect of low standby power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

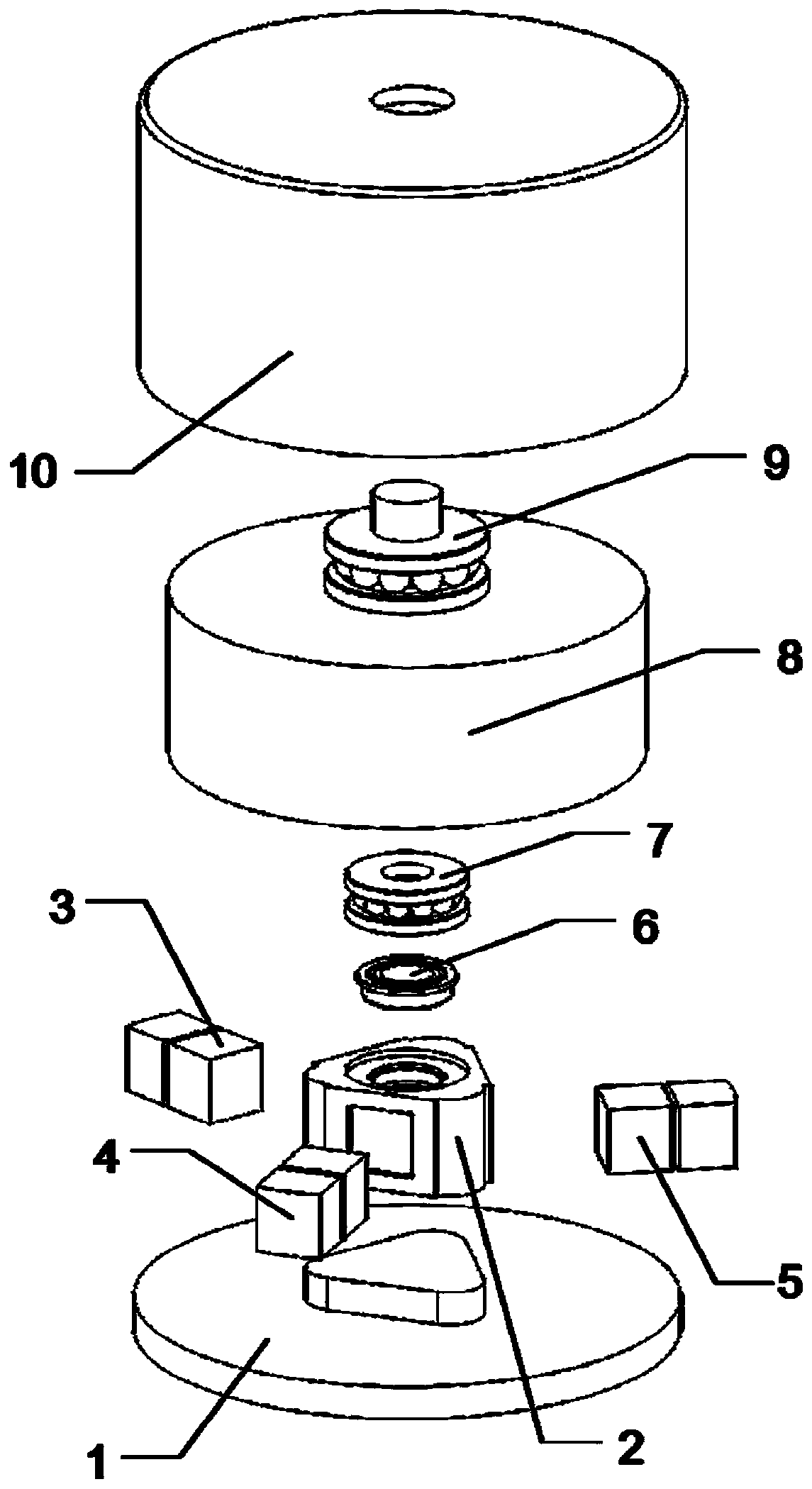

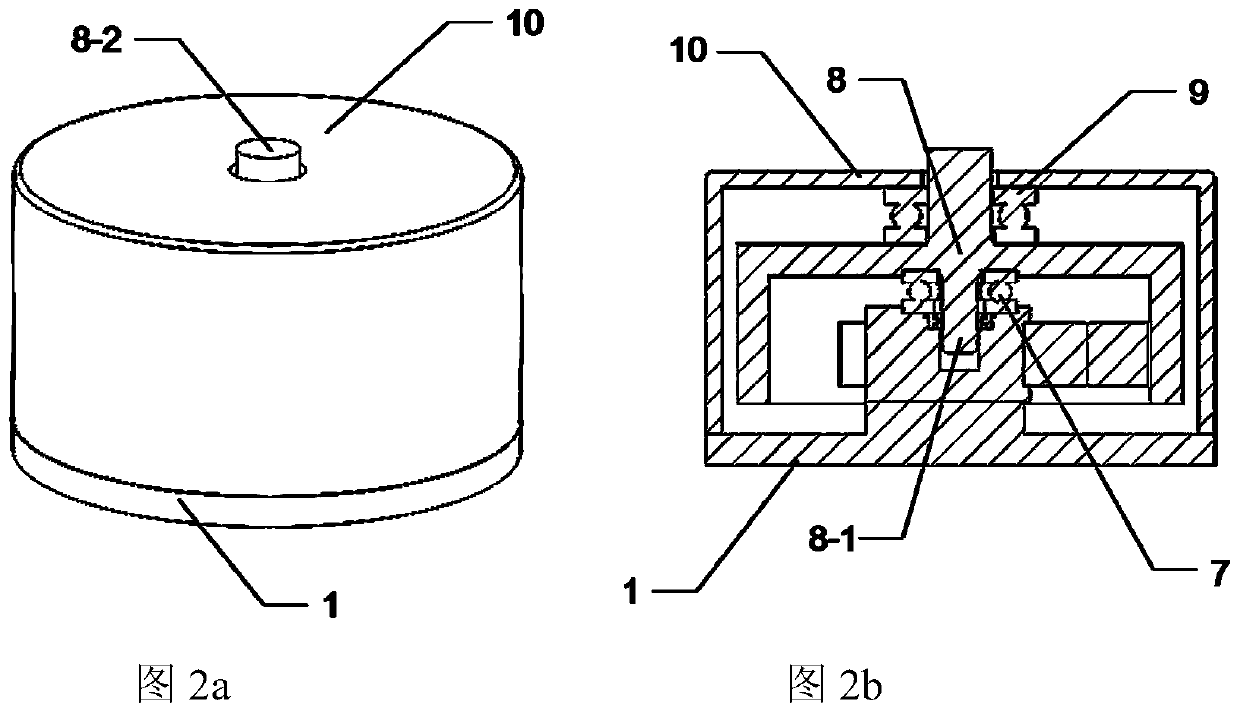

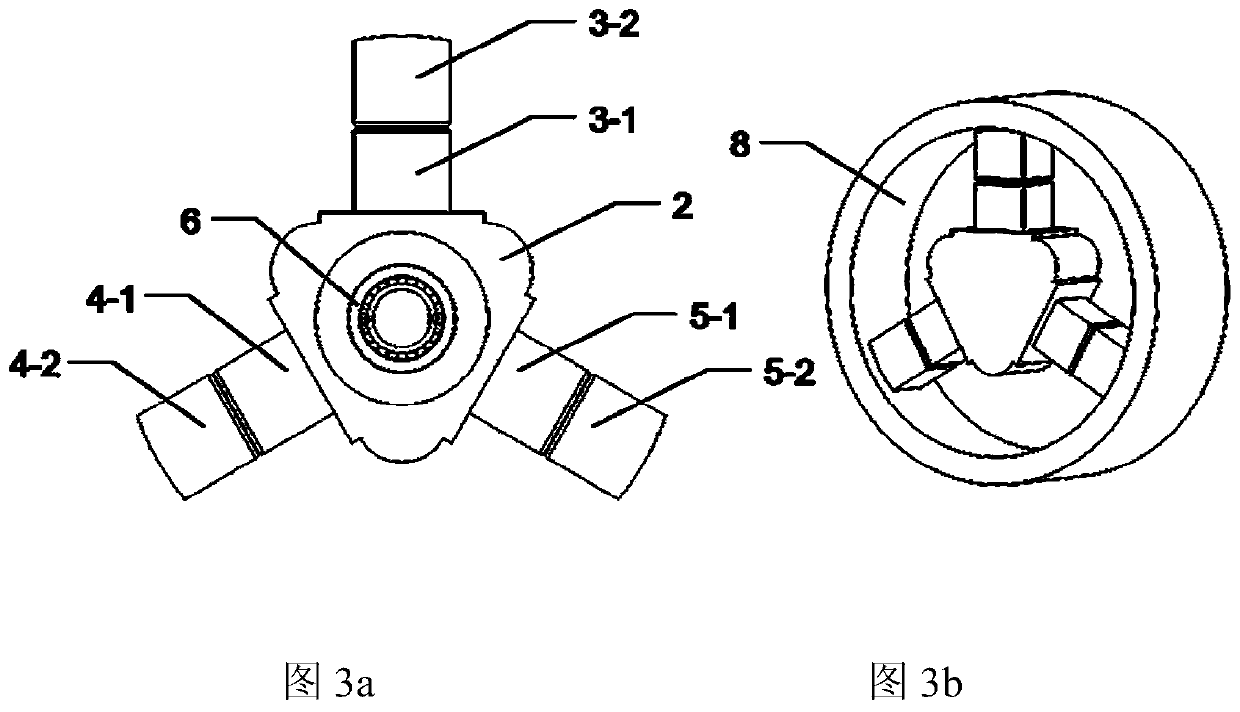

[0023] like figure 1 and figure 2 middle figure 2 a and figure 2 As shown in b, the present invention is a linear-shear piezoelectric ceramic cooperatively driven stepping and rotating actuating device, comprising an actuator base 1, which is installed on the base 1 and can fix the first piezoelectric ceramic group 3, the second piezoelectric ceramic group The actuators of the piezoelectric ceramic group 4 and the third piezoelectric ceramic group 5 rotate the stator 2, the rolling bearing 6 is embedded in the upper side of the actuator rotating stator 2, the lower thrust ball bearing 7 is installed above the rolling bearing 6, and the actuator rotates the rotor 8. The lower actuator rotating rotor limit shaft 8-1 is installed in the rolling bearing 6 and the lower thrust ball bearing 7, and the upper thrust on the output shaft 8-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com