Direct Buried Half Armored Cable

An armored cable, direct buried technology, applied in the field of direct buried semi-armored cables, can solve the problems of no buffering capacity, insufficient shear resistance, poor protection ability, etc., and achieve a clear appearance, good strength, good The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

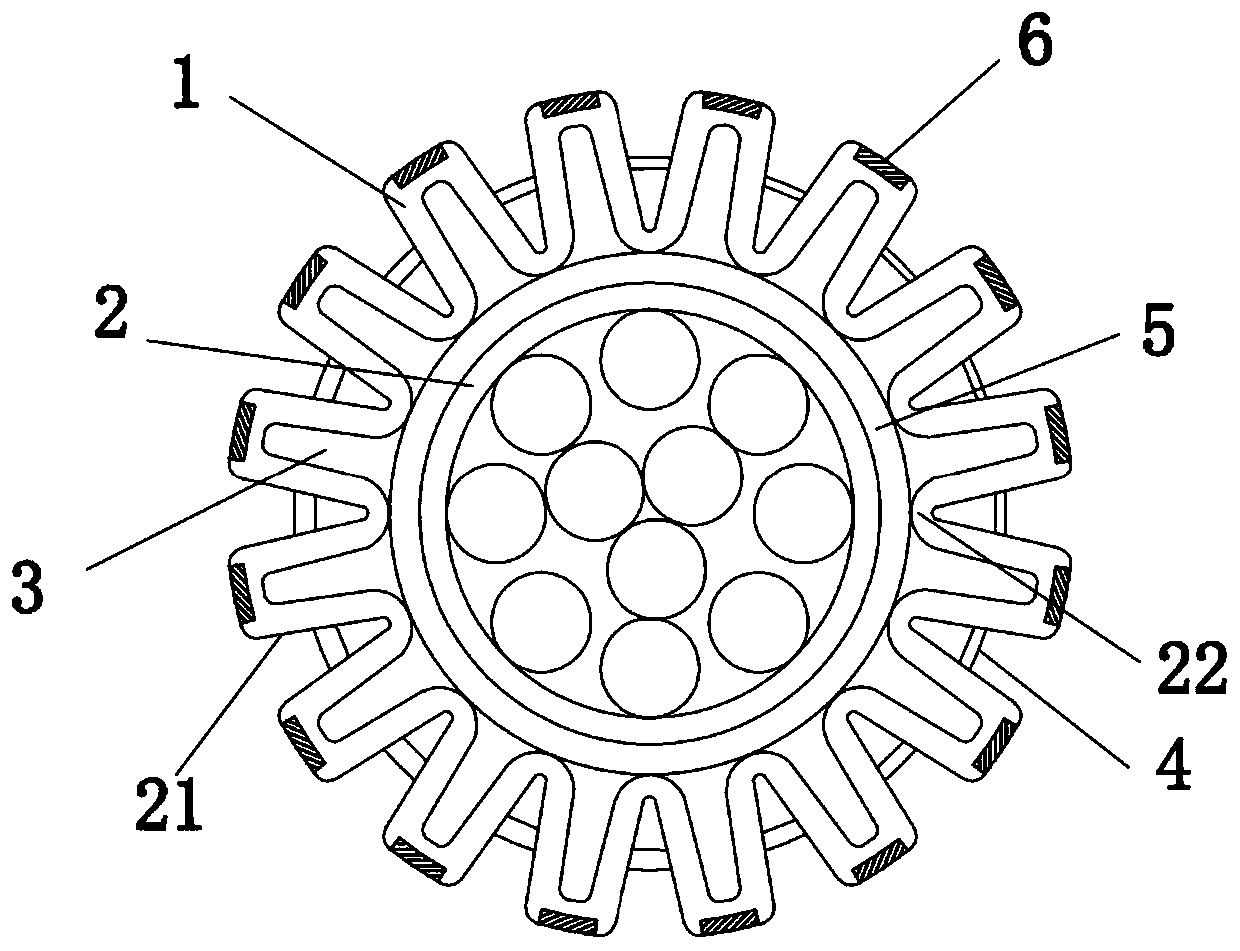

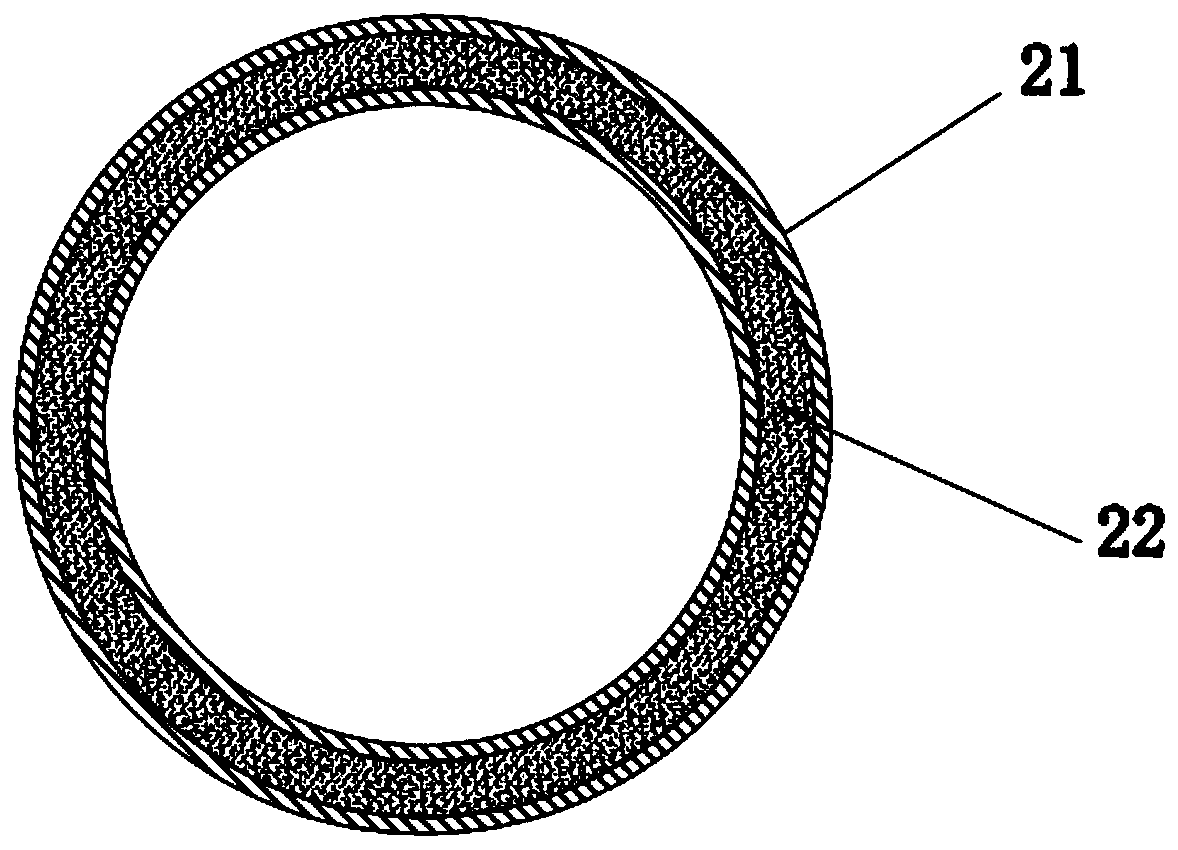

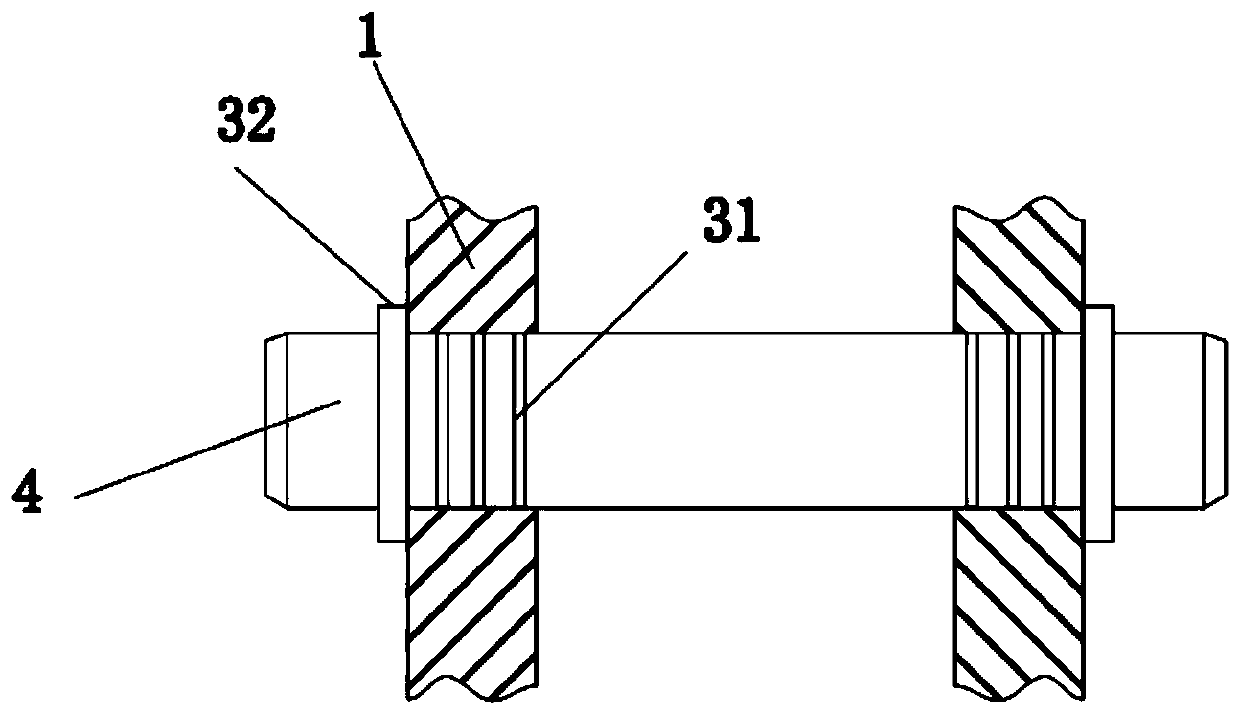

[0018] Such as figure 1 As shown, the direct-buried semi-armored cable includes a cable outer layer 1 and an inner core wire 2 arranged in the cable outer layer 1. The cable outer layer 1 has an installation cavity 3, and the inner core wire 2 is set In the installation cavity 3, the inner core wire 2 is wrapped with a layer of expansion layer 5, and the outer layer 1 of the cable is bent to form more than one support segment 22 extending inward, and each support segment 22 surrounds the outer layer 1 of the cable once. The inner side end of the support section 22 is set and supported in contact with the outer wall of the expansion layer 5, and a clamp 21 is formed between more than one support section 22, and more than one clamp is provided equidistantly on both sides of the clamp inner wall around the outer layer of the cable. Positioning through holes (not shown), a sealing connection section 4 is inserted between the adjacent positioning through holes on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com