A method and equipment for efficiently and economically removing antimony in printing and dyeing wastewater

An economical technology for printing and dyeing wastewater, applied in the direction of combustion methods, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of high chemical cost, low treatment efficiency, large dosage, etc., and achieve reduced chemical cost and low chemical cost , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

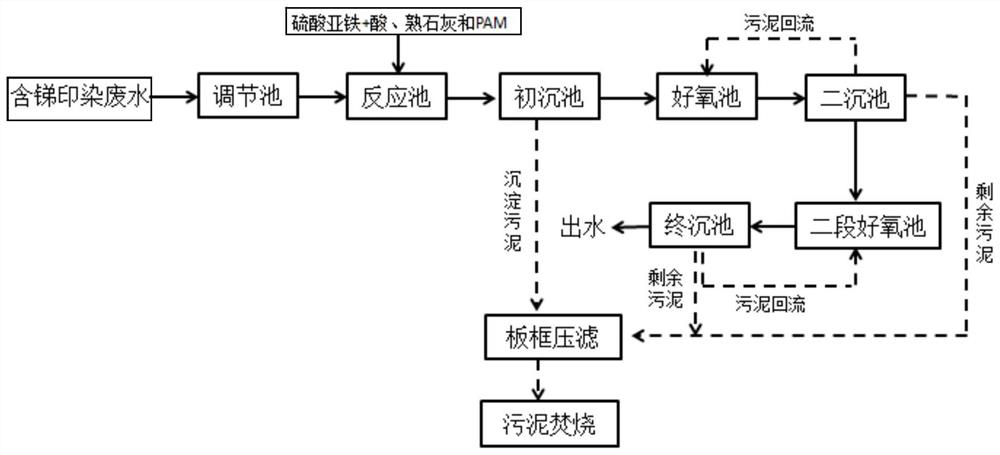

[0035] Embodiment 1: In this embodiment, a method for efficiently and economically removing antimony in printing and dyeing wastewater is to use the printing and dyeing wastewater of a printing and dyeing enterprise according to figure 1 The process is carried out, and the antimony concentration in the printing and dyeing wastewater containing antimony is 3330.6 μ g / L, including the following steps:

[0036] (1) Antimony-containing printing and dyeing wastewater enters the reaction pool from the regulating tank, and hydrochloric acid dissolved in ferrous sulfate is first added to the reaction tank. , the mass ratio of ferrous sulfate in hydrochloric acid containing ferrous sulfate to antimony-containing printing and dyeing wastewater is 600ppm, and then add slaked lime and anionic polyacrylamide (PAM, Henan Haiyun Environmental Protection Technology Co., Ltd.), and the dosages are respectively 60ppm and 2ppm, that is, the mass of slaked lime accounted for 60ppm in the antimony...

Embodiment 2

[0040] Embodiment 2: In this embodiment, a method for efficiently and economically removing antimony in printing and dyeing wastewater is to use antimony-containing printing and dyeing wastewater from a printing and dyeing enterprise according to figure 1 The process is carried out, and the antimony concentration in the printing and dyeing wastewater containing antimony is 2822.5μg / L, including the following steps:

[0041] (1) Antimony-containing printing and dyeing wastewater enters the reaction tank from the adjustment tank, and first adds hydrochloric acid dissolved in ferrous sulfate in the reaction tank. Slaked lime and anionic polyacrylamide (PAM, Henan Haiyun Environmental Protection Technology Co., Ltd.), the dosage is 80ppm and 3ppm respectively, 200r / min rapid mixing reaction 2min;

[0042] (2) The wastewater after the reaction enters the primary sedimentation tank, the effluent pH of the primary sedimentation tank is 7.5, and the antimony concentration is 258.3 μg / L....

Embodiment 3

[0045] Embodiment 3: In this embodiment, a method for efficiently and economically removing antimony in printing and dyeing wastewater is to use antimony-containing printing and dyeing wastewater from a printing and dyeing enterprise according to figure 1 The process is carried out, and the antimony concentration in the printing and dyeing wastewater containing antimony is 2525.4 μ g / L, including the following steps:

[0046] (1) The antimony-containing printing and dyeing wastewater enters the reaction pool from the regulating tank, and in the reaction tank, first mixed with hydrochloric acid dissolved in ferrous sulfate and potassium permanganate, wherein, the dosage of ferrous sulfate is the mass of antimony in the antimony-containing printing and dyeing wastewater The concentration is 71.3 times that of 180ppm, and the dosage of potassium permanganate is 0.56 times of that of ferrous sulfate, that is, 100ppm. Add slaked lime and anionic polyacrylamide (PAM, Henan Haiyun Env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com