Disc core material storage and feeding device

A technology of feeding device and disk core, which is applied in the direction of conveyor, transportation and packaging, and unstacking of objects, etc. It can solve the problems that manual paper sticking plates cannot meet the needs of production, the sticking quality is different, and the efficiency is low, so as to save The effect of labor cost, reduction of labor intensity and improvement of supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

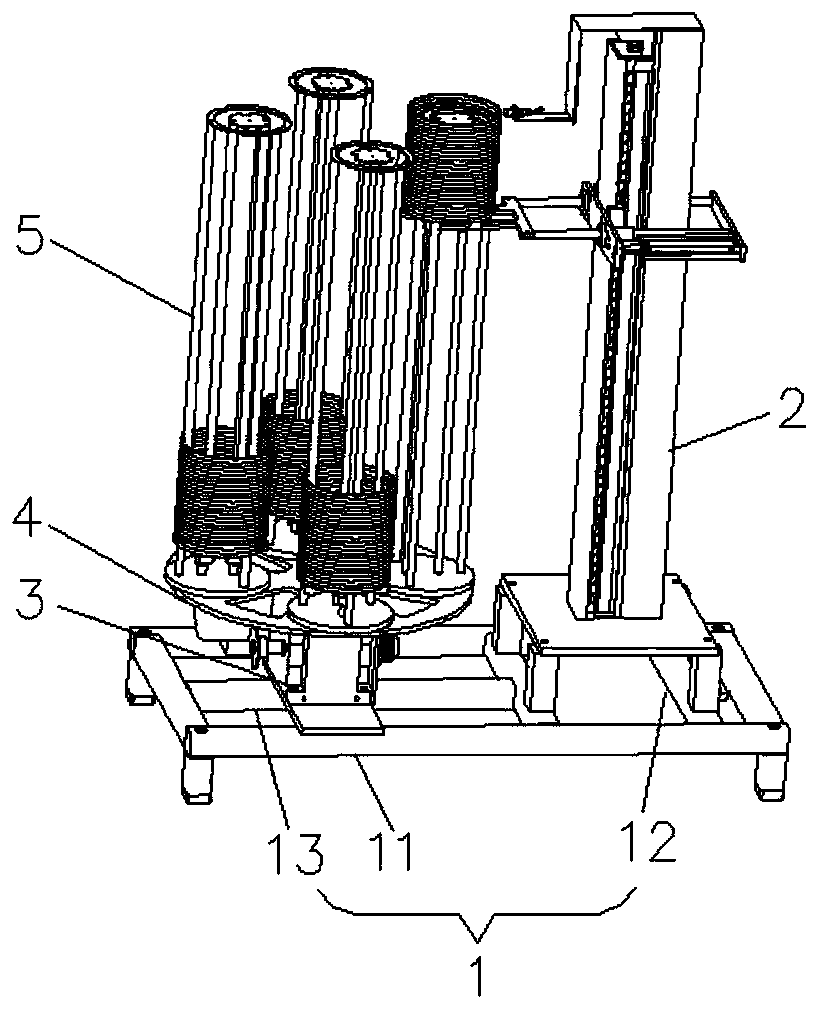

[0022] see figure 1 , The core storage and feeding device of the present invention includes a bracket 1 , a core feeding device 2 , a drive assembly 3 , a rotating member 4 and a core storage device 5 .

[0023] The bracket 1 is used for fixing the core feeding device 2 and the driving assembly 3 . In this embodiment, the bracket 1 includes a surrounding arm 11 , a first fixing plate 12 and a second fixing plate 13 , and the first fixing plate 12 and the second fixing plate 13 are respectively fixed on the surrounding arm 11 . The core feeding device 2 is fixed on the first fixing plate 12 , and the driving assembly 3 is fixed on the second fixing plate 13 . The support 1 is not limited to the structural form described in this embodiment, and any other structure capable of fixing the core feeding device 2 and the driving assembly 3 is acceptable.

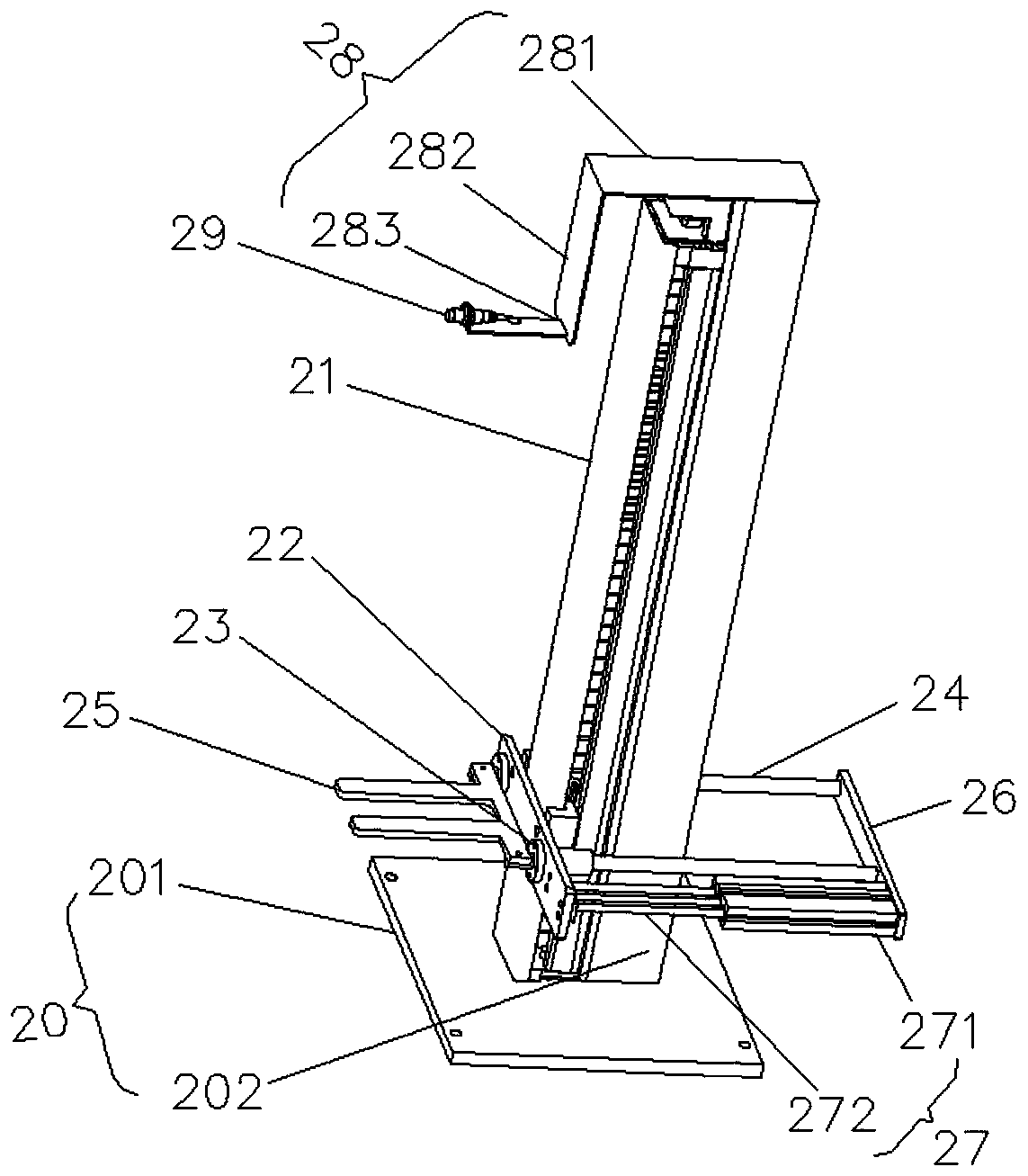

[0024] see figure 2 , the core feeding device 2 includes a module frame 20, a guide rod 21, a fixed plate 22, a locking member...

Embodiment 2

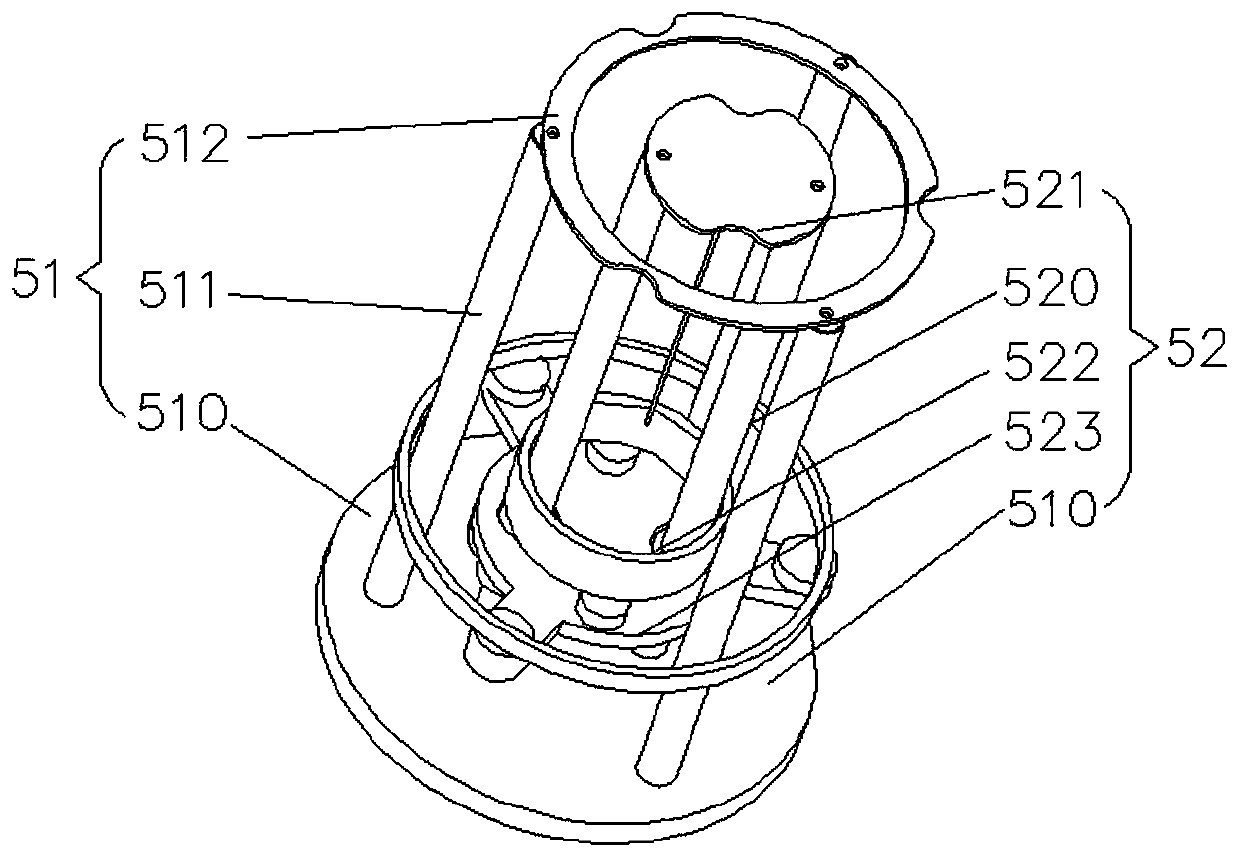

[0037] The difference between this embodiment and Embodiment 1 is that the four groups of small disk storage assemblies 52 on the disk core storage device 5 are filled with small-sized disk cores.

[0038] In summary, the embodiment of the disk core storage and feeding device of the present invention has the beneficial technical effects of:

[0039] 1. During the processing, the operator only needs to place the disk core in the disk core storage and feeding device 5 in parallel. When the disk core storage device 5 turns to the working position of the disk core feeding device 2, the cylinder 27 drives The push plate 25 is pushed out to the bottom of the support member 56. At this time, the guide rod 21 drives the push plate 25 to rise, and the push plate 25 drives the support member 56 to move upward, so that the core group as a whole rises. So as to realize the storage and automatic feeding of the disk core, and prepare for the automatic sticking of the disk;

[0040] 2. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com