Automatic longitudinal-cutting system for corrugated boards

A kind of plank and automatic technology, which is applied in the direction of sawing equipment, wood processing equipment, circular saws, etc., can solve the problems of continuous slitting, low setting accuracy, and low production efficiency, and achieve labor cost reduction and labor intensity. The effect of low and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

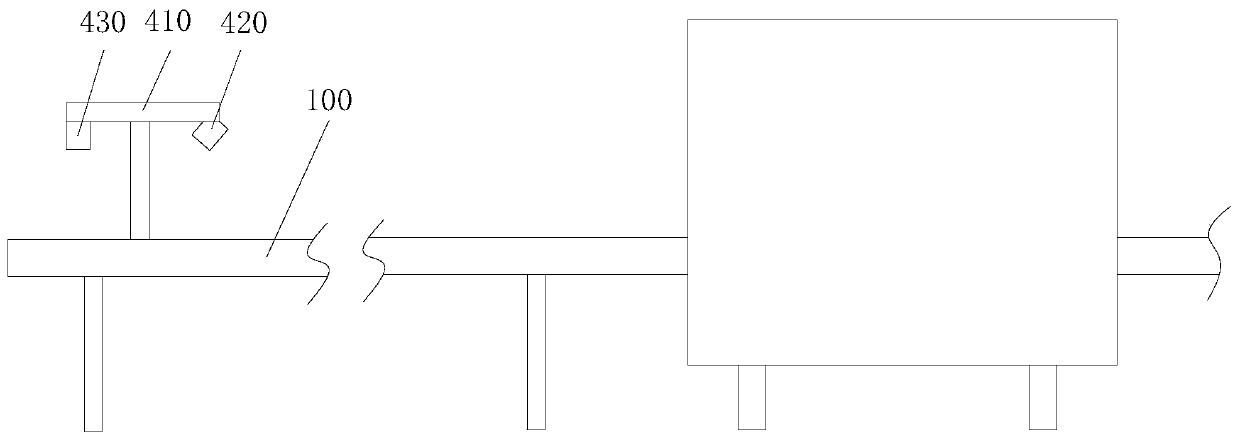

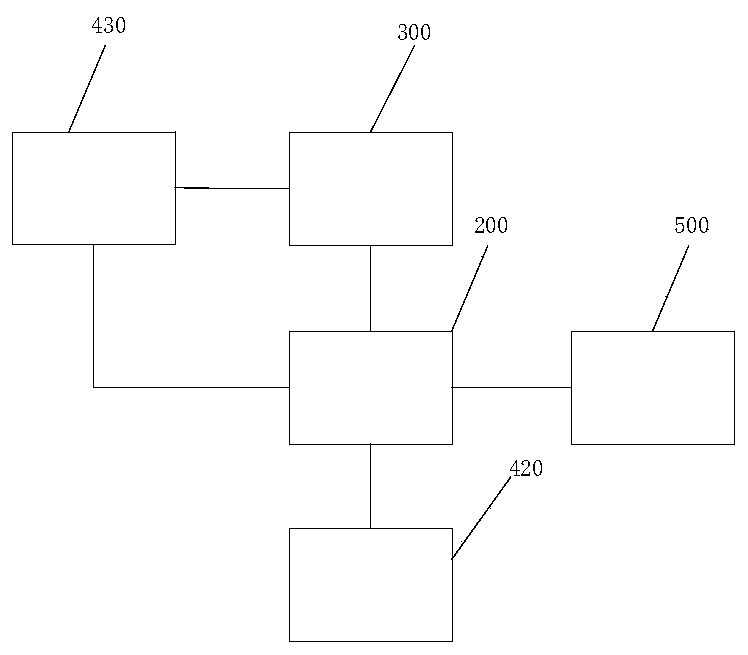

[0049] Such as figure 1 As shown, an automatic slitting system for corrugated wood boards includes a disc multi-blade saw body, the disc multi-blade saw body includes a conveying roller table 100, a saw blade adjustment mechanism, and the driving device 500 of the saw blade adjustment mechanism is a motor. It also includes a controller 200 , an industrial computer 300 and an online measuring device arranged on the conveying roller table 100 .

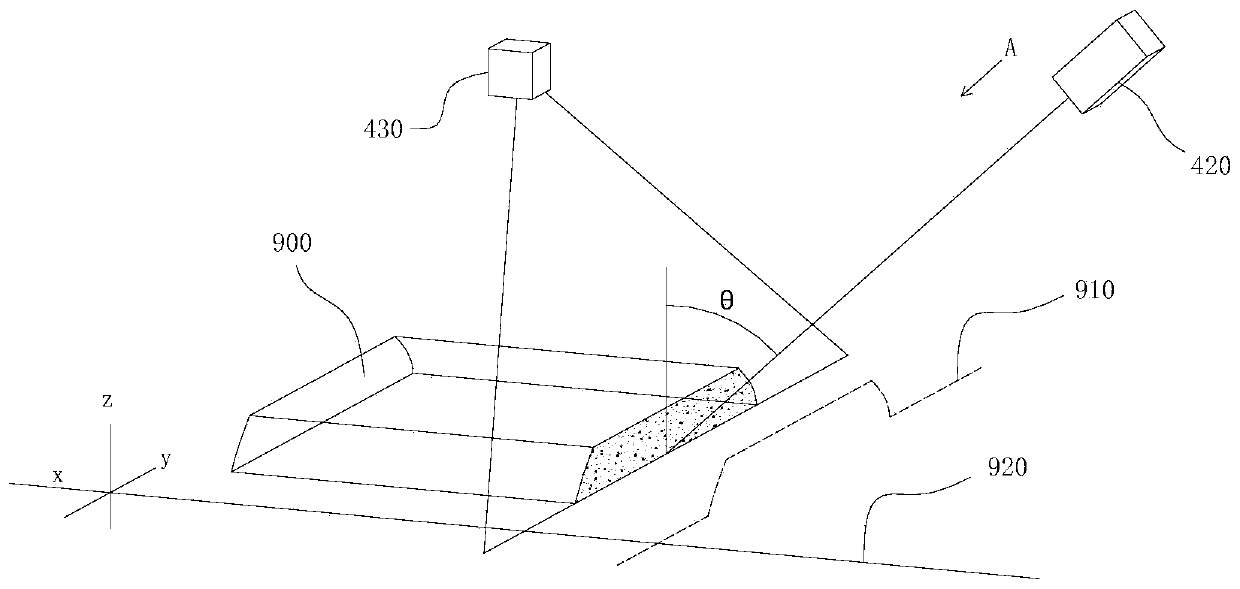

[0050] The online measuring device is used to detect the size of the corrugated wood board, and it includes a fixed bracket 410 , an imaging device 420 and a light source 430 installed on the fixed bracket 410 . The image-taking device 420 is used to obtain the profile figure of the section of a certain point of the corrugated wood boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com