Method for sucking liquid in vacuum negative pressure state

A technology of vacuum suction and negative pressure, which is applied in the direction of liquid variable displacement machinery, pump control, non-variable displacement pumps, etc. It can solve the problems of unreachable suction equipment, impurities, high cost, etc., and achieve reduction in equipment volume and operation Integrity, wide selection range, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] A method for pumping liquid under vacuum negative pressure.

[0026] The vacuum tank type oil-water separation device of the oil filter adopts a continuous working system, and uses low-temperature vacuum evaporation to remove moisture in the oil. The vacuum in the vacuum tank is generated by a vacuum exhaust device, and the oil after removing moisture is in a vacuum Under negative pressure, it needs to be continuously output from the vacuum tank, and the separated oil may not be sucked out by using a common high-suction pump, but it can be reliably realized according to the method of the present invention, and the measures are as follows:

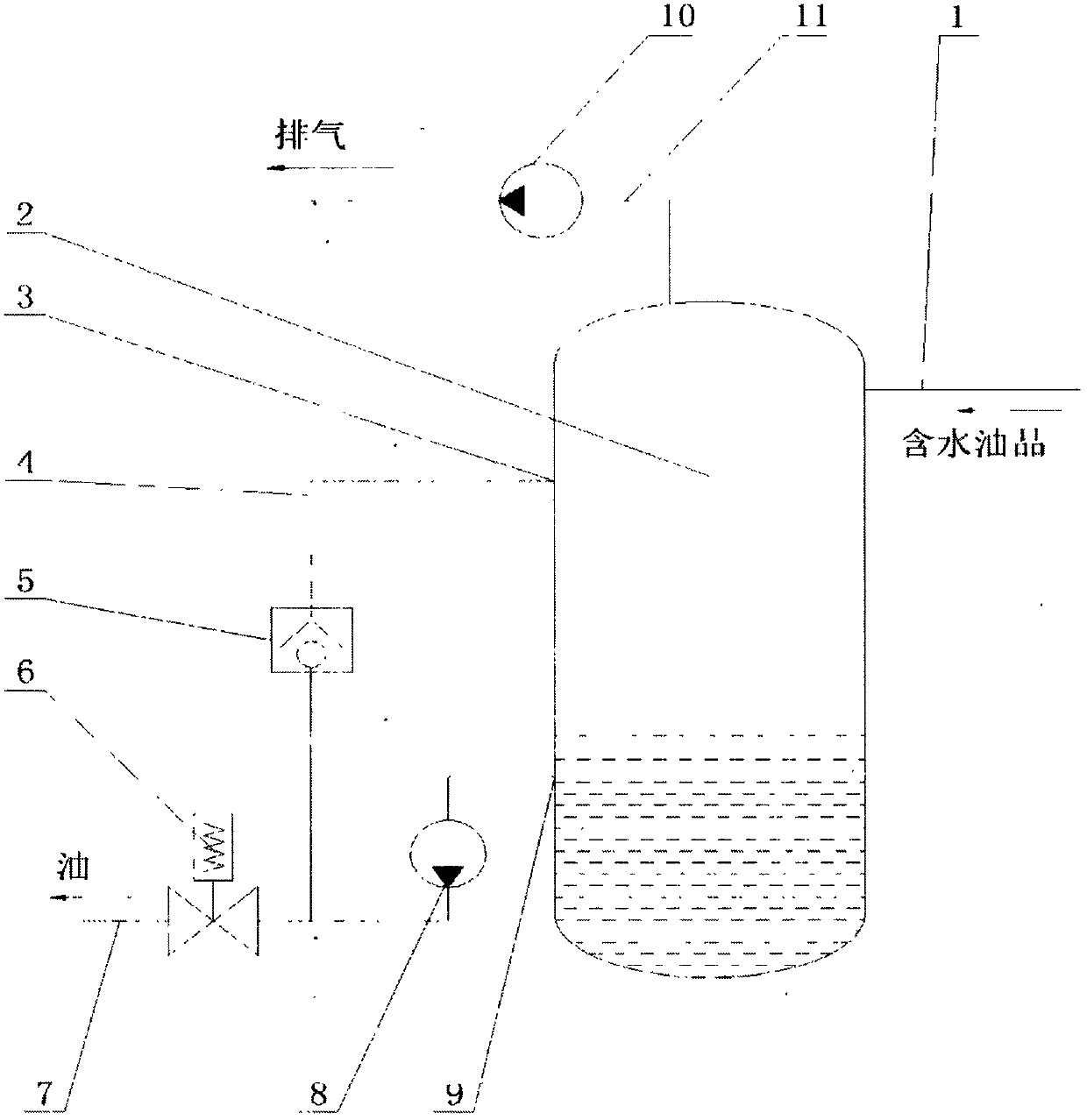

[0027] The water-containing oil enters the vacuum separation tank 2 from the liquid inlet pipeline 1, and the vacuum in the tank is maintained by the vacuum pump 10 and the exhaust pipeline 11; a liquid outlet 9 is opened at a height below the oil level in the vacuum separation tank 2, and is installed in the vacuum separation tank 2....

Embodiment example 2

[0029] A method for pumping liquid under vacuum negative pressure.

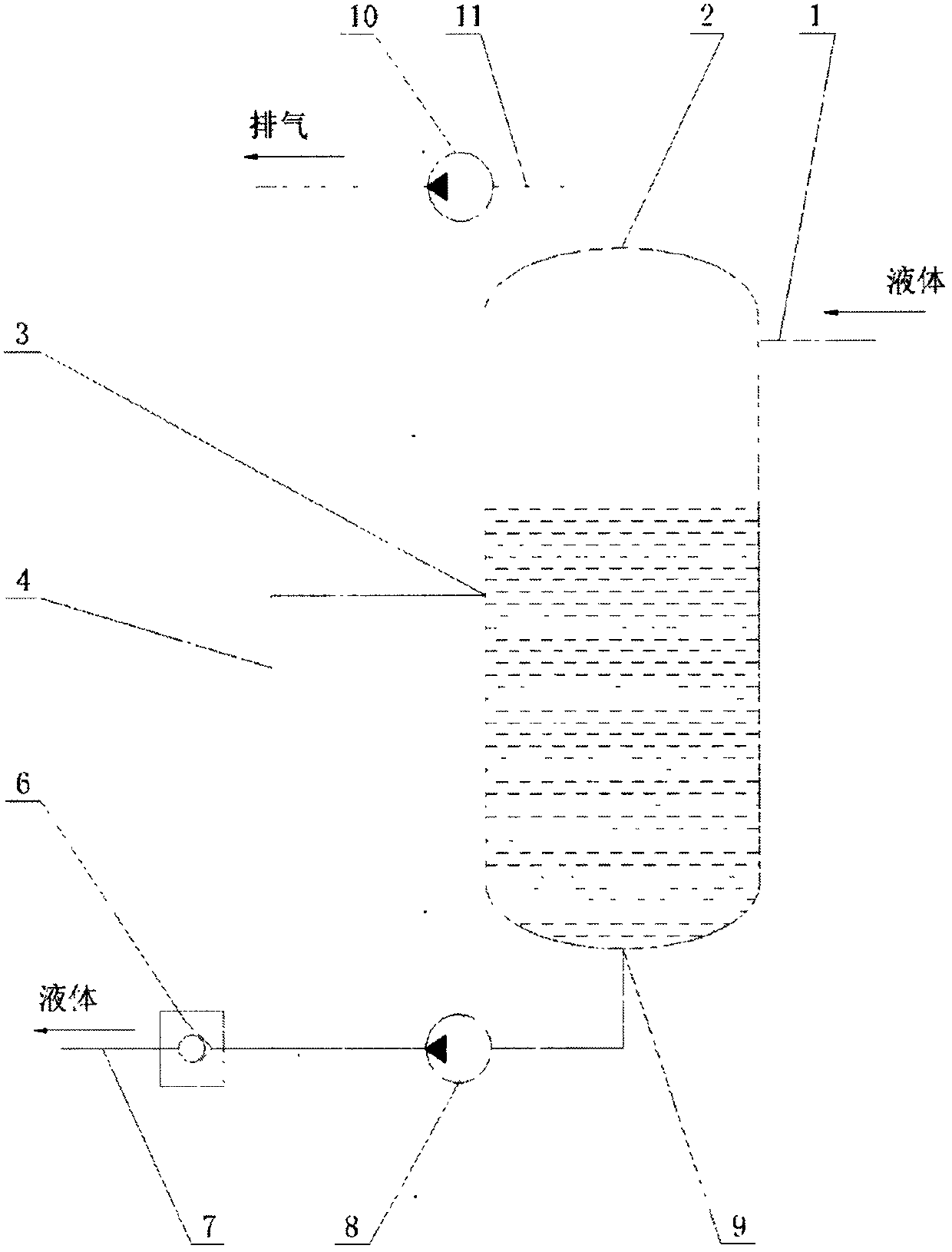

[0030] The vacuum degassing device used to remove gas in water, the liquid enters the vacuum separation tank 2 from the liquid inlet pipeline 1 under negative pressure (in this case, the vacuum degassing tank), the height below the liquid surface in the vacuum separation tank 2 Open a liquid outlet 9, communicate with the inlet of the suction device 8 (in this case, a centrifugal pump) installed below this height, communicate with the valve 6 and the output pipeline 7 at the outlet of the suction device 8, where the valve 6 It is a one-way valve; a pipeline is set up between the outlet of the suction device and the one-way valve to communicate with the vacuum separation tank 2 through a damping tube as a pressure balance pipeline 4; the pressure balance pipeline 4 is opened on the vacuum separation tank 2 The pressure balance port 3 is higher than the liquid outlet 9; in this case, the vacuum pump 11 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com