A digital printing machine

A digital printing machine and rack technology, applied in printing, typewriters, printing devices, etc., can solve the problems of pattern tearing or offset, lower fabric printing quality, and easy offset, etc., to facilitate collection and transportation, increase Effects of color fastness and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

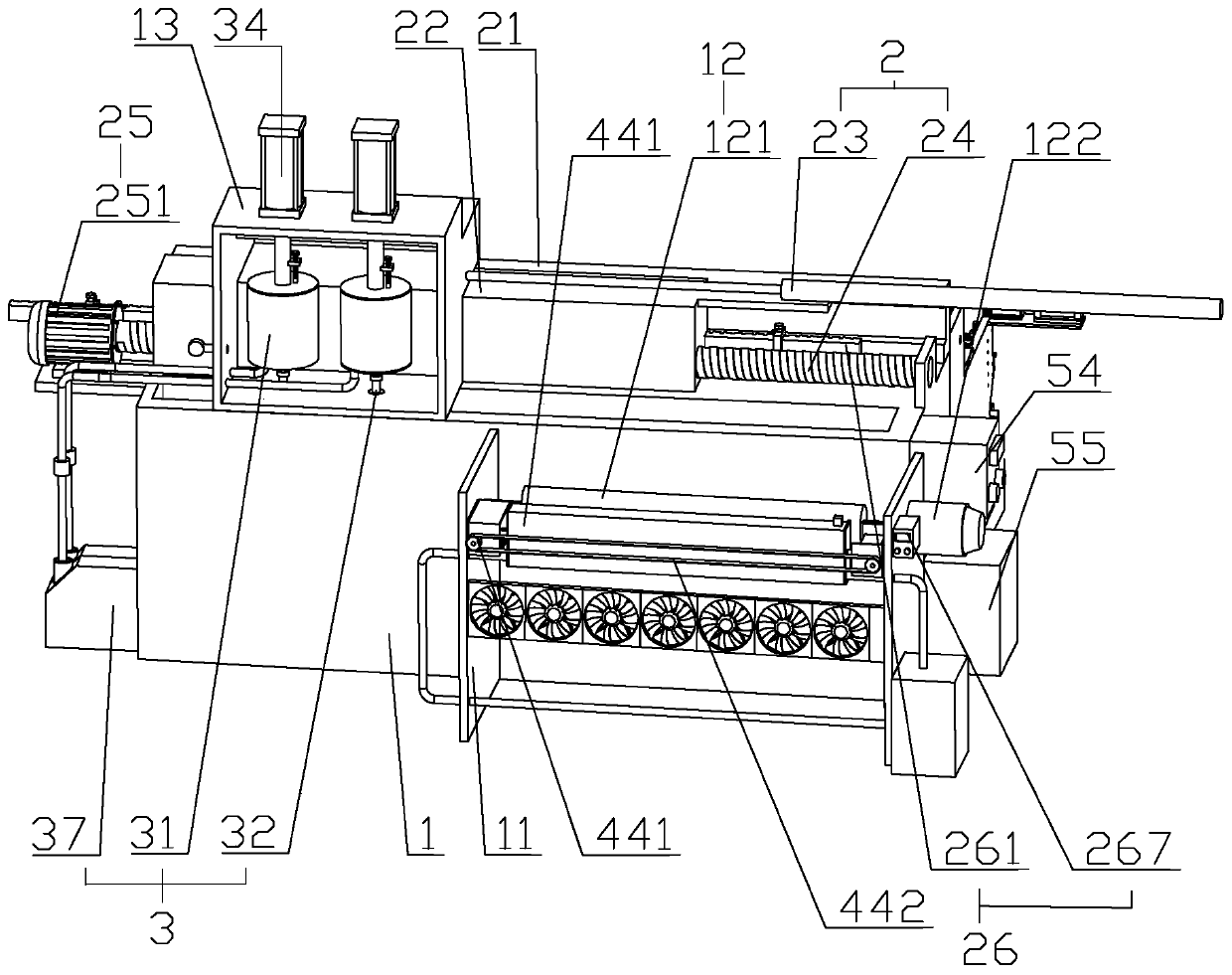

[0039] refer to figure 1 , is a digital printing machine disclosed by the present invention, comprising a frame 1, a transmission mechanism 12 arranged on the frame 1 for conveying cloth, a head 13 for inkjet slidingly arranged on the frame 1, a drive The transmission mechanism 2 for the slide of the machine head 13, and the collecting mechanism 3 for ink supply arranged on the frame 1. The transmission mechanism 12 includes a plurality of transmission rollers 121 that are rotatably connected to the frame 1 through bearings, and a drive motor 122 that is fixed to the frame 1 by screws. The drive motor 122 drives the transmission rollers 121 to rotate through a belt. The transmission rollers 121 are cylindrical In a body shape, the cloth passes around a plurality of conveying rollers 121 to be transported.

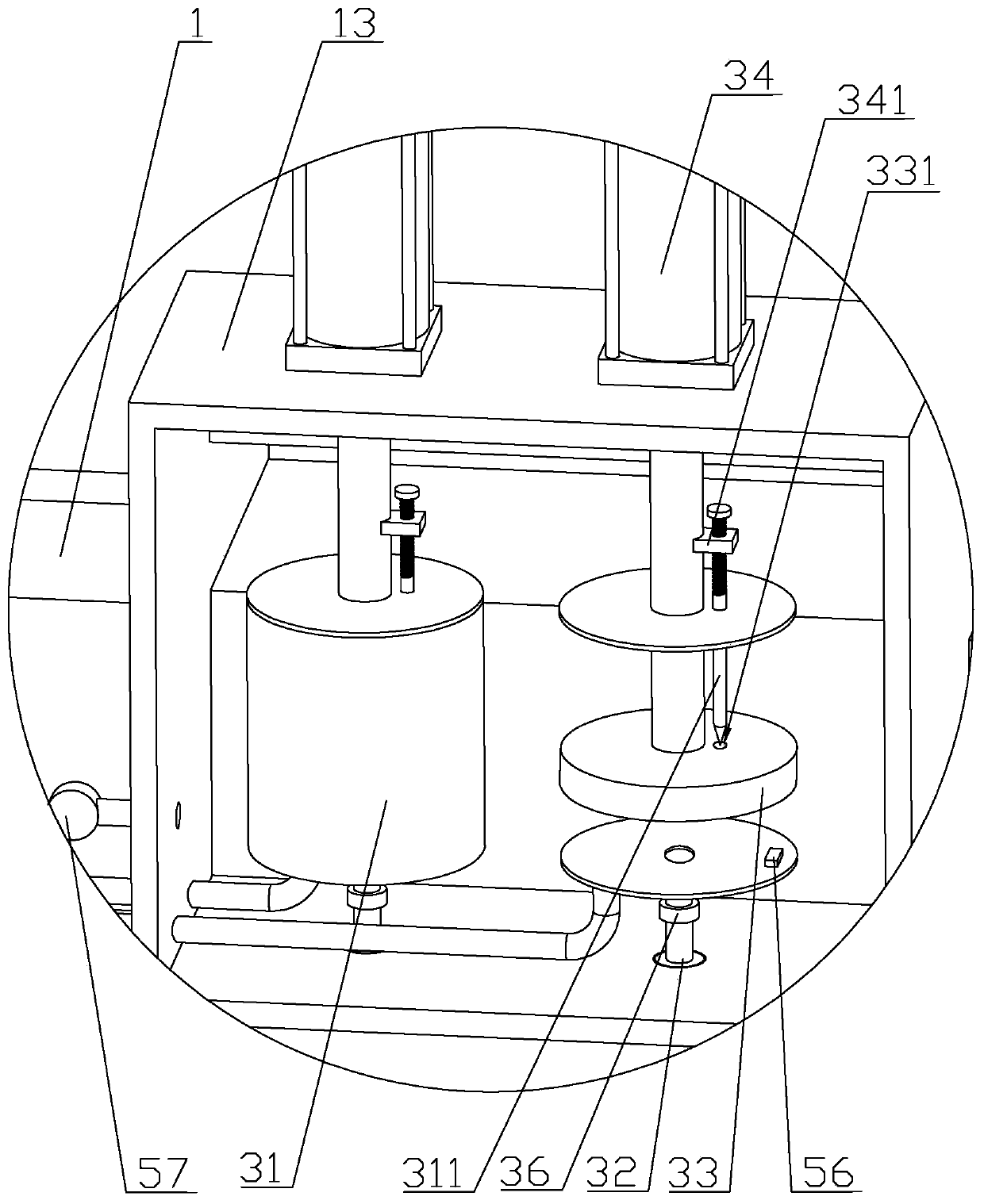

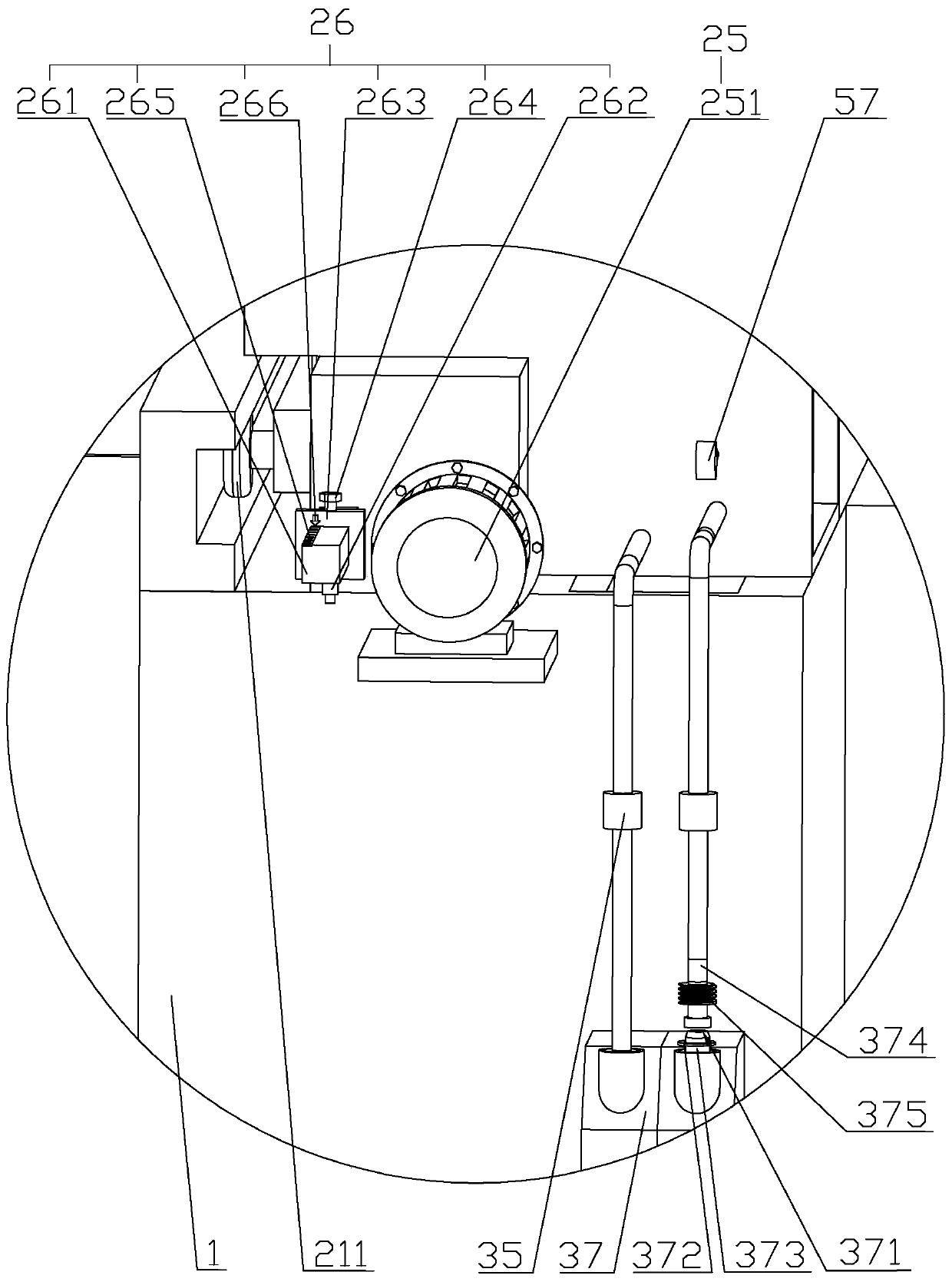

[0040] refer to figure 2 , image 3 , the head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com