A magnetron variable friction and variable leg length soft crawling robot

A crawling robot, variable friction technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of low power density, slow response speed, non-adjustable leg length, etc., to achieve the effect of improving power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0030] Embodiments of the present invention provide a magnetically controlled variable friction and variable leg length soft crawling robot, including a variable friction mechanism and a variable leg length mechanism.

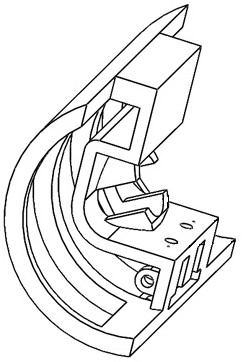

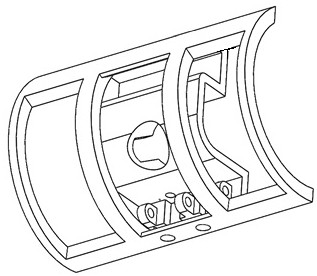

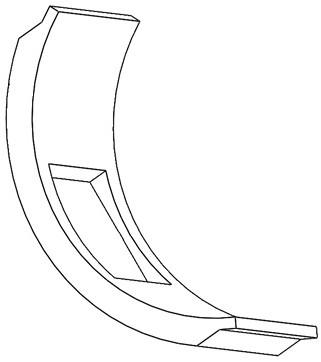

[0031] like Figures 1 to 6 As shown, the variable friction mechanism includes a bracket 1 , a torsion spring 2 , a magnet 3 , an iron sheet 4 , a variable friction sheet 5 , and a rubber sheet 6 . The bracket 1 includes an arcuate inner layer and an arcuate outer layer. A through hole is arranged in the middle of the arcuate inner layer for fixing the cylindrical magnet 3. The arcuate outer layer passes through the slope structure and the steps of the variable friction plate 5. The surface is matched to fix the variable friction plate 5, the outer side of the variable friction plate 5 is pasted with a rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com