High-speed rotary cup dismounting and mounting tool

A high-speed, tool-based technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of high-speed rotary cup falling off, cutting high-speed rotary cup, lack of strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

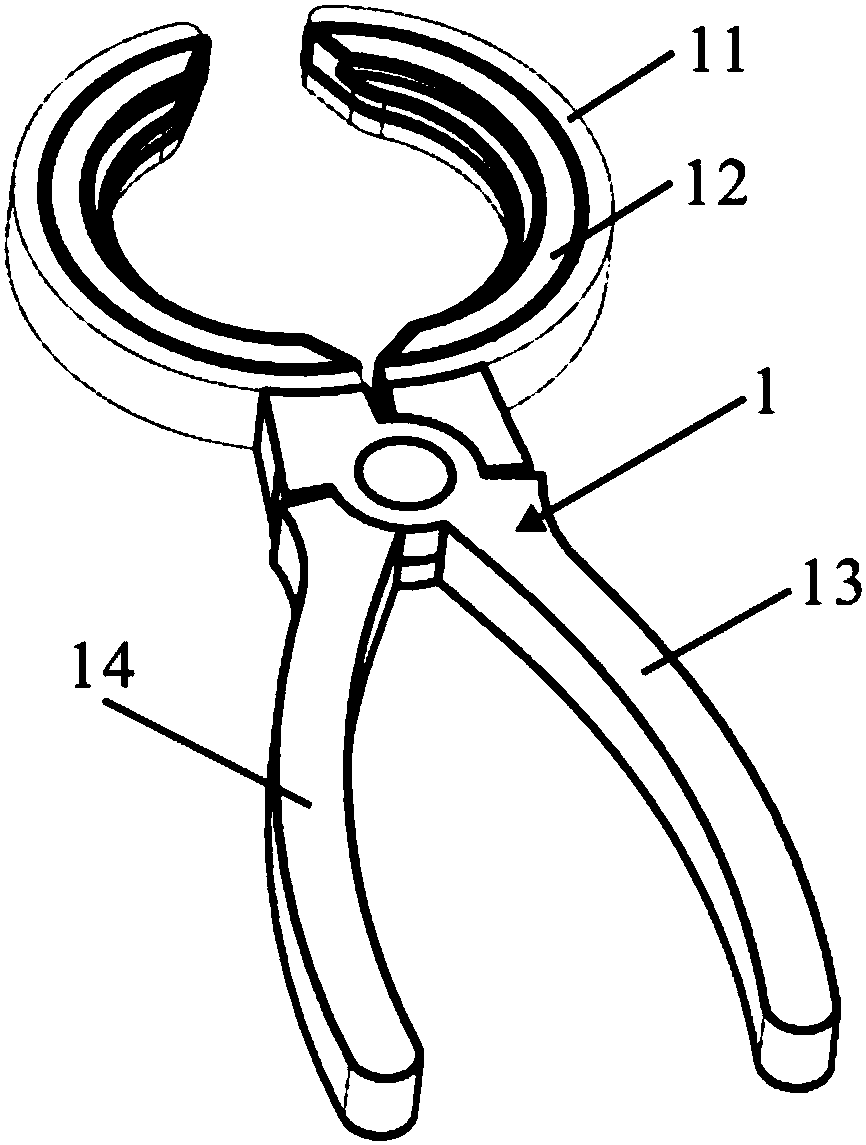

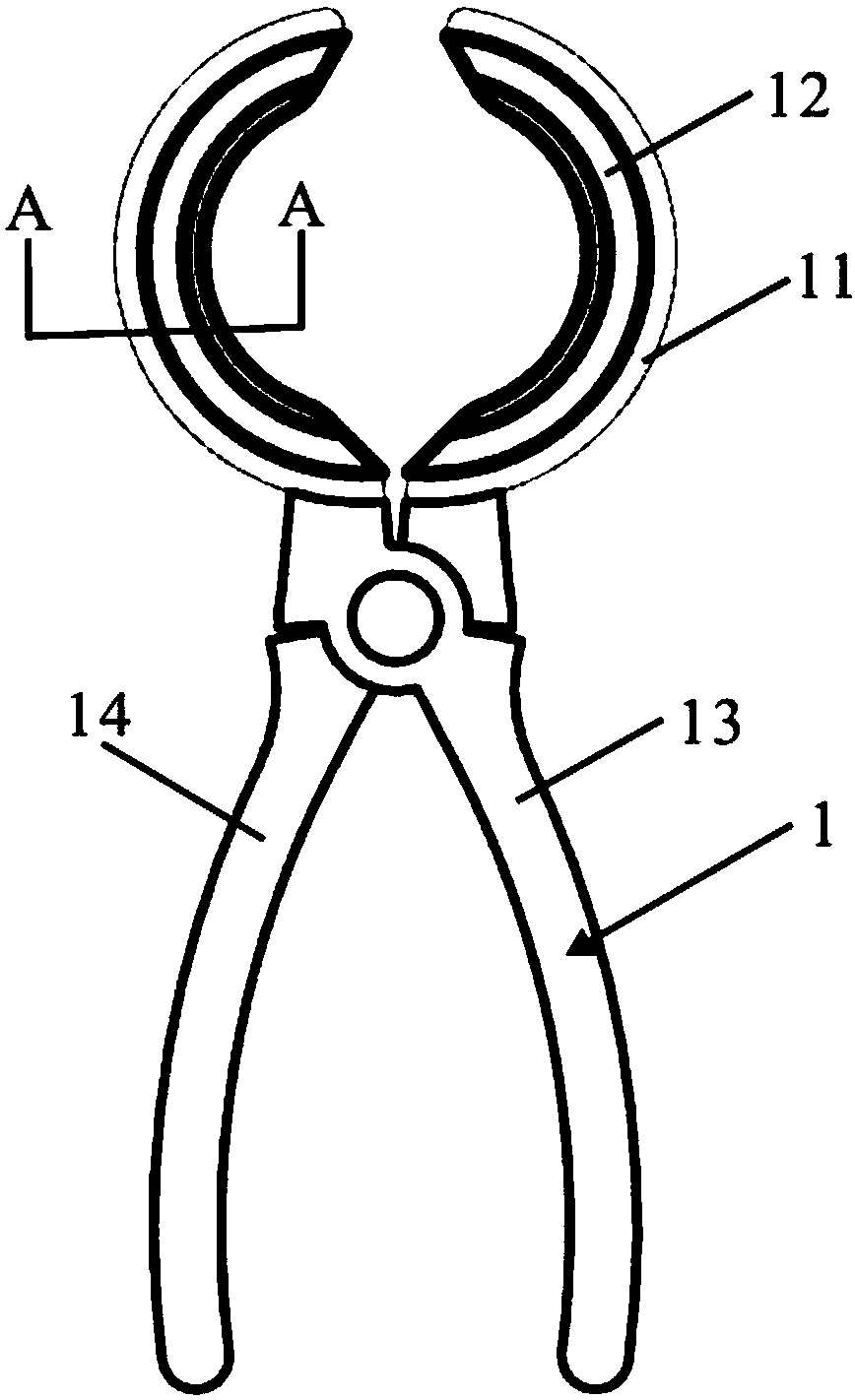

[0019] The following with attached Figure 1 to Figure 3 A dismounting tool for a high-speed rotary cup of the present invention will be further described in detail.

[0020] A disassembly tool for a high-speed rotary cup of the present invention, please refer to Figure 1 to Figure 3 Relevant figures include a pliers body 1, the pliers body 1 includes a left pliers handle 14 and a right pliers handle 13, the middle part of the left pliers handle 14 and the middle part of the right pliers handle 13 are mutually hinged, and the left pliers handle 14 The front end and the inner side of the front end of the right pliers handle 13 are respectively fixedly connected or integrally formed with a left clamping part and a right clamping part, the left clamping part and the right clamping part are arranged oppositely, and the inner wall of the left clamping part And the inner wall of the right clamping part is releasably offset against the high-speed rotary cup. Like this, pliers body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com