Novel permanent magnet brushless bench drill

A technology of permanent magnet brushless and bench drilling, which is applied in the direction of boring/drilling, large fixed members, drilling/drilling equipment, etc. It can solve the problems of power grid quality factor decline, aggravated power grid load, motor impact, etc., to achieve The effect of improving the quality factor, improving the efficiency of the whole machine and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present invention is a new type of permanent magnet brushless bench drill, and its use method can be carried out in the following steps: The present invention is a new type of permanent magnet brushless bench drill. "Tower pulley" transmission mechanism; the use of permanent magnet brushless motor has the following advantages:

[0047] 1. After the permanent magnet is embedded in the rotor of the permanent magnet synchronous motor, the rotor magnetic field is established by the permanent magnet. During normal operation, the rotor and the stator magnetic field run synchronously. There is no induced current in the rotor, and there is no rotor resistance loss. This is the only item It can improve the motor efficiency by 4% to 50%. Since there is no induction current excitation in the rotor of the hydromagnetic motor, the stator winding may be a purely resistive load, so that the power factor of the motor is almost 1, and the motor has a wide range of applications and a...

Embodiment 2

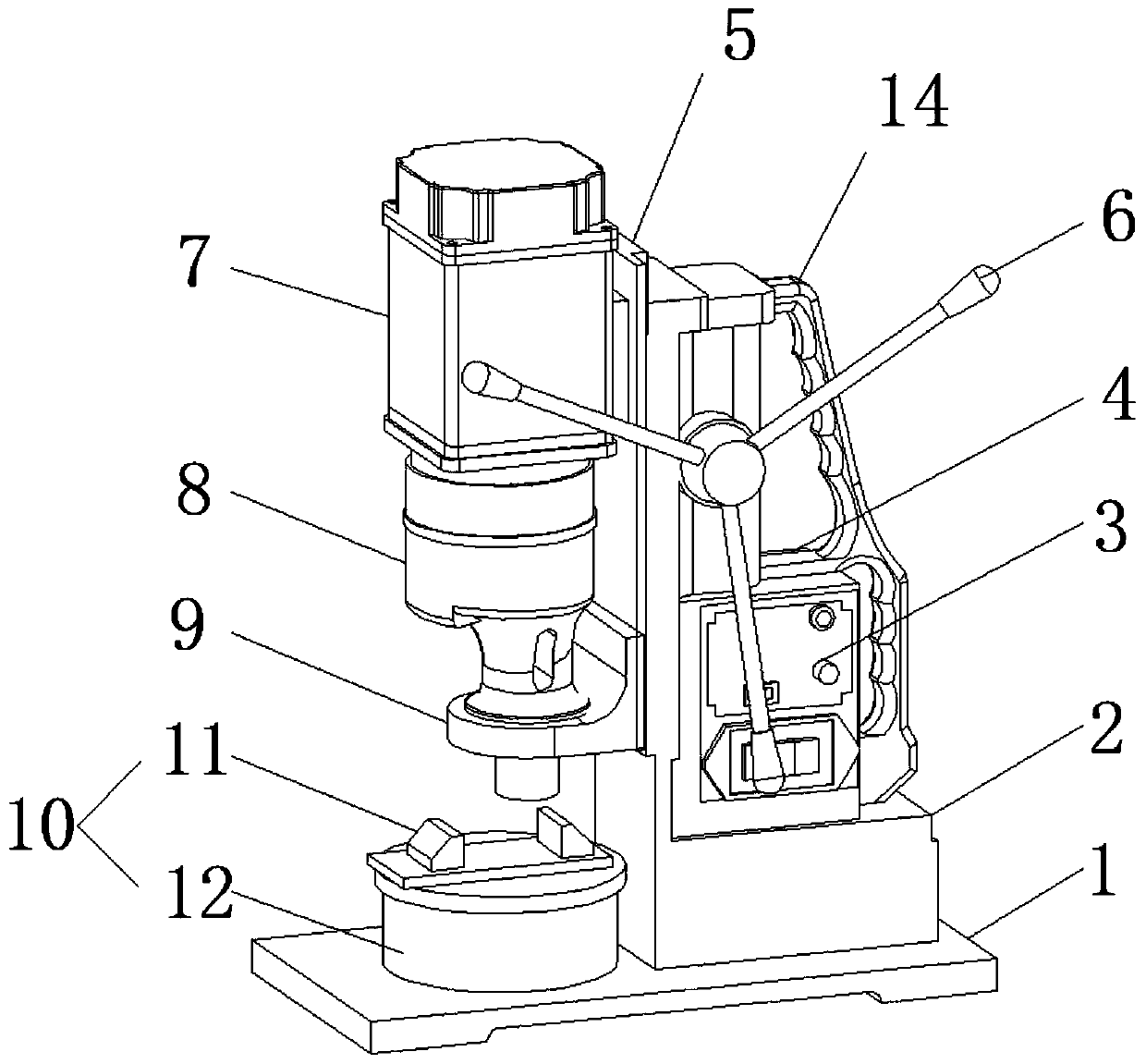

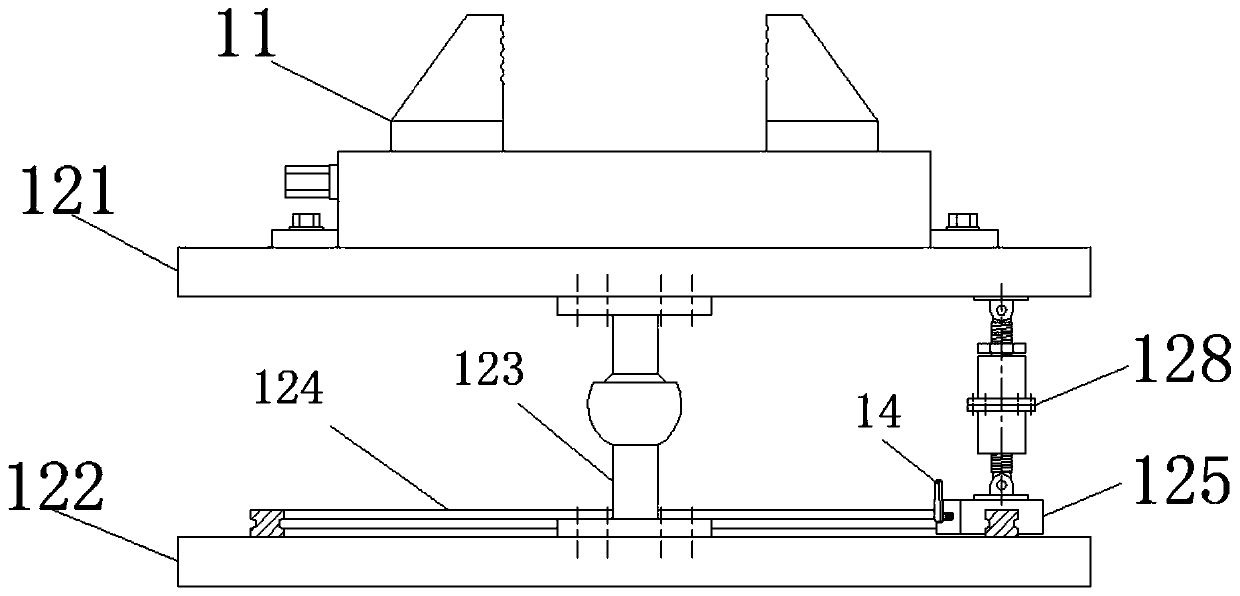

[0053] The top front side of the bench drill base plate 1 of the present invention is provided with a universal clamping table 10 for clamping and processing workpieces, and the universal clamping table 10 includes a bench vice 11 and a universal adjustment mechanism arranged at the bottom of the bench vice 11 12. Through the universal adjustment mechanism 12, corresponding adjustments can be made according to the special positional relationship between the required processing surface and the workpiece mounting surface, which can effectively reduce the difficulty of workpiece clamping and processing.

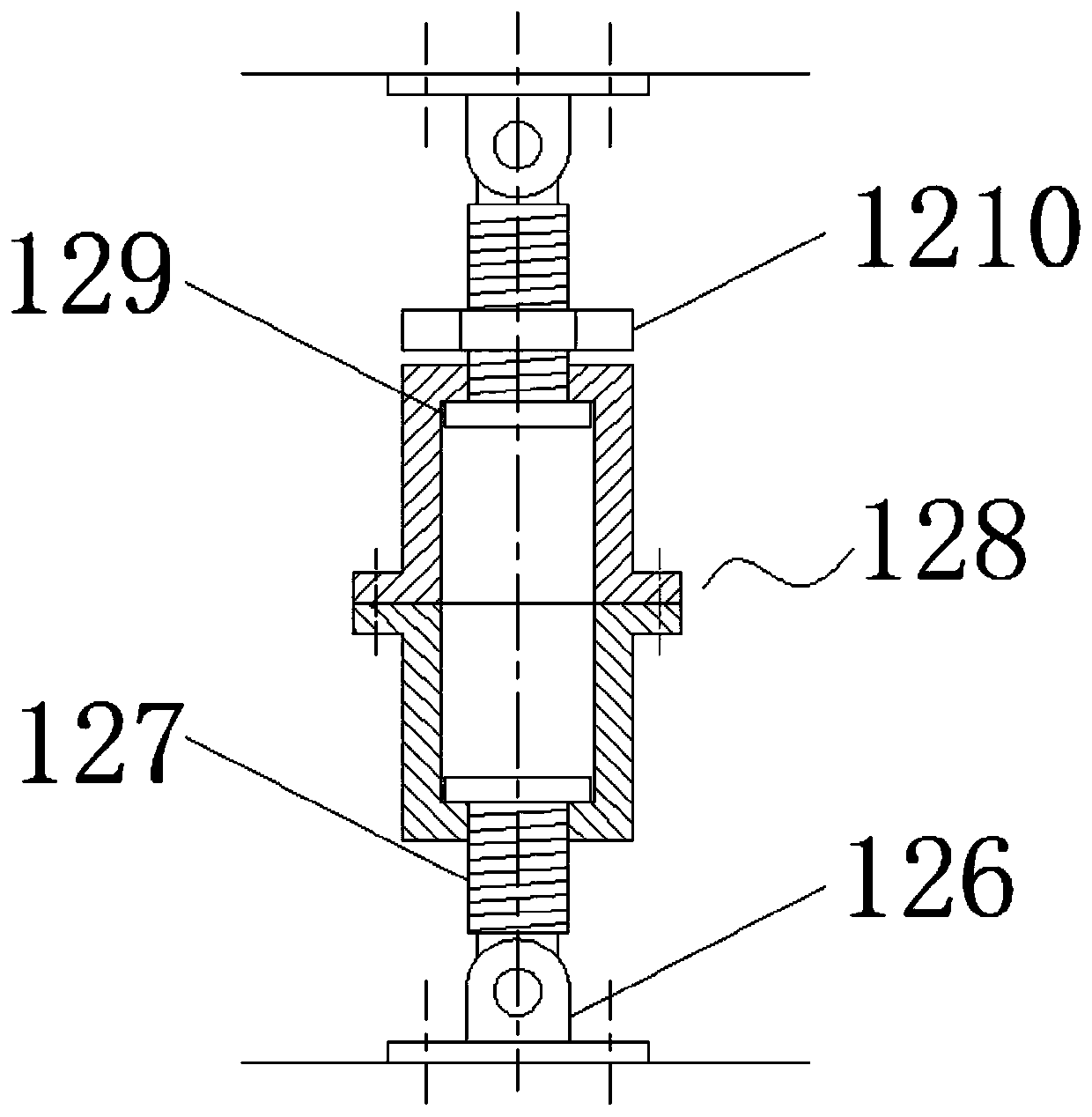

[0054] Specifically, when adjusting the inclination angle of the bench vise 11 and the upper fixing plate 121, first loosen the lock nut 1210, and then rotate the connecting sleeve 128. Adjust the total length of the screw rod 127 so that the upper fixed plate 121 can rotate a certain angle around the universal ball hinge on the adjustable support column 123 to realize the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com