Low temperature performance analysis method for rock asphalt-modified asphalt

A technology of modified asphalt and low temperature performance, applied in the preparation of test samples, material inspection products, etc., can solve the problems of ambiguous evaluation indicators, inability to truly analyze the low temperature performance of modified asphalt, etc., to facilitate drying and heating The effect of melting, preventing uneven heating, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0082] Embodiments 1 to 6 of the present invention disclose a method for preparing rock asphalt modified asphalt:

[0083] (a) Sieve the Buton Rock Asphalt (BRA) with a 0.15 mm square hole sieve to obtain 100 mesh Buton Rock Asphalt particles, which are then placed in an oven at 100 ° C for drying;

[0084] (b) Put the AH-70 base asphalt in an oven at 150°C for 1 hour; then put it on an electric furnace for heating at 150°C, and use glass rods to stir during the heating process to prevent uneven heating of the asphalt. At the same time, insert a mercury thermometer to strictly control the temperature during the heating process to prevent the asphalt from aging due to excessive temperature;

[0085] (c) According to the dosage disclosed in Table 1, add the above-mentioned AH-70 matrix asphalt to the high-speed shearer, and shear at a temperature of 160-170°C. After adding the base asphalt, gradually adjust the rotation speed to 3000rpm so that the Buton rock asphalt is evenly ...

Embodiment 7

[0090] Calculate the equivalent brittle point of the asphalt-modified asphalt prepared in the above-mentioned Examples 1-6, and the results are shown in Table 2 below:

[0091] (A) measure the penetration P of the rock asphalt modified asphalt prepared in Examples 1 to 6 at different temperatures;

[0092] (B) Calculate lgP from the P obtained from the above measurements, and then perform linear fitting on lgP at different temperatures to obtain the regression equation lgP=K+A×T;

[0093] (C) Substitute P=0.12mm into the above regression equation to get Calculate the modified brittle point T 1,2 , which is the equivalent brittle point;

[0094] (D) According to the regression parameter A of the regression equation, according to the formula Calculate the asphalt penetration index PI;

[0095] (E) Analysis of the low-temperature performance of asphalt-modified bitumen based on equivalent brittle point and bitumen penetration index.

[0096] The degree of fit is obtained b...

Embodiment 8

[0102] Calculate the work-to-break and tensile compliance of the asphalt-modified asphalt prepared in Examples 1-6 above, and the results are shown in Table 3 below:

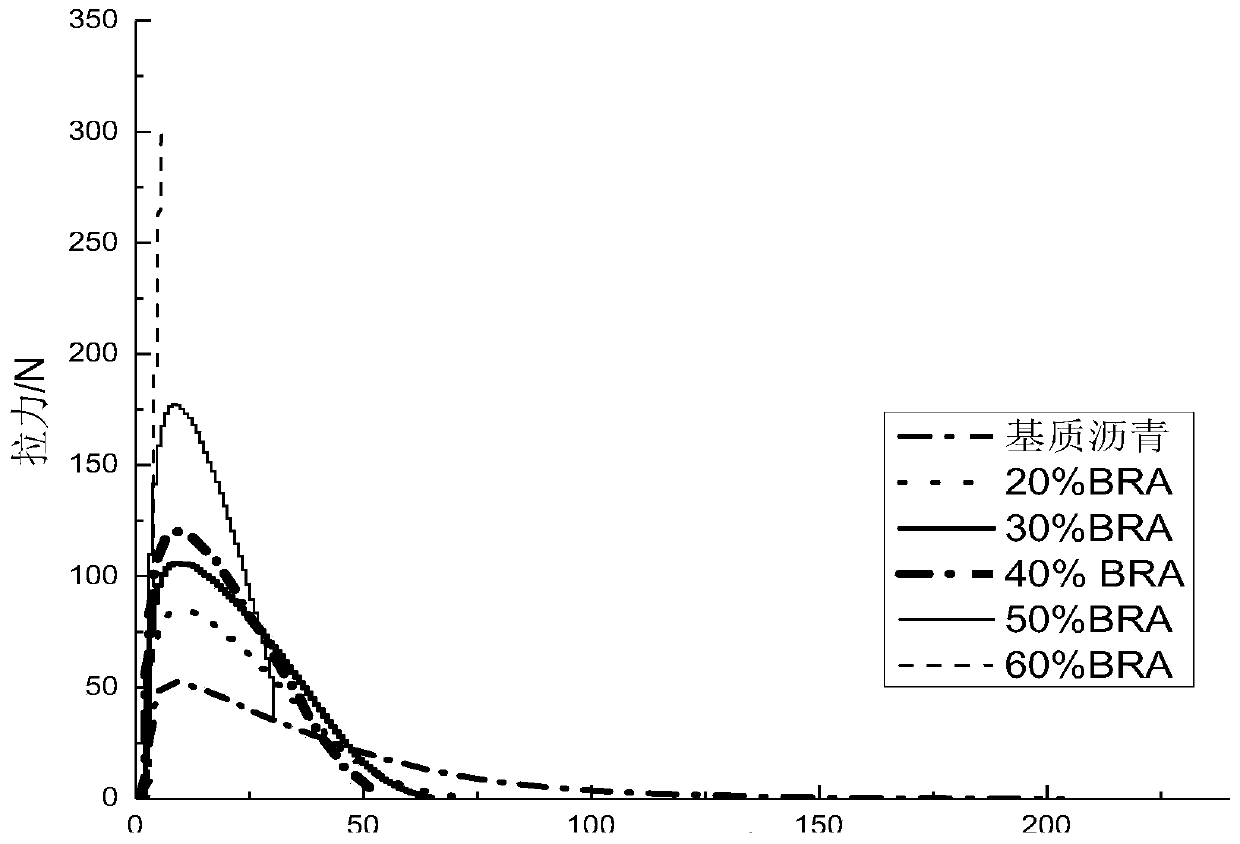

[0103] A, the rock bituminous modified asphalt that embodiment 1~6 prepares is carried out measuring force ductility test, can obtain the tensile force and ductility relation curve of rock bituminous modified asphalt, as figure 1 shown;

[0104] B. Calculate the area enclosed by the relationship curve and the X-axis, which is the breaking work;

[0105] C. According to the relationship curve, calculate the ratio of the tensile force at the peak of the curve to the fracture ductility, which is the tensile compliance.

[0106] table 3

[0107]

[0108]

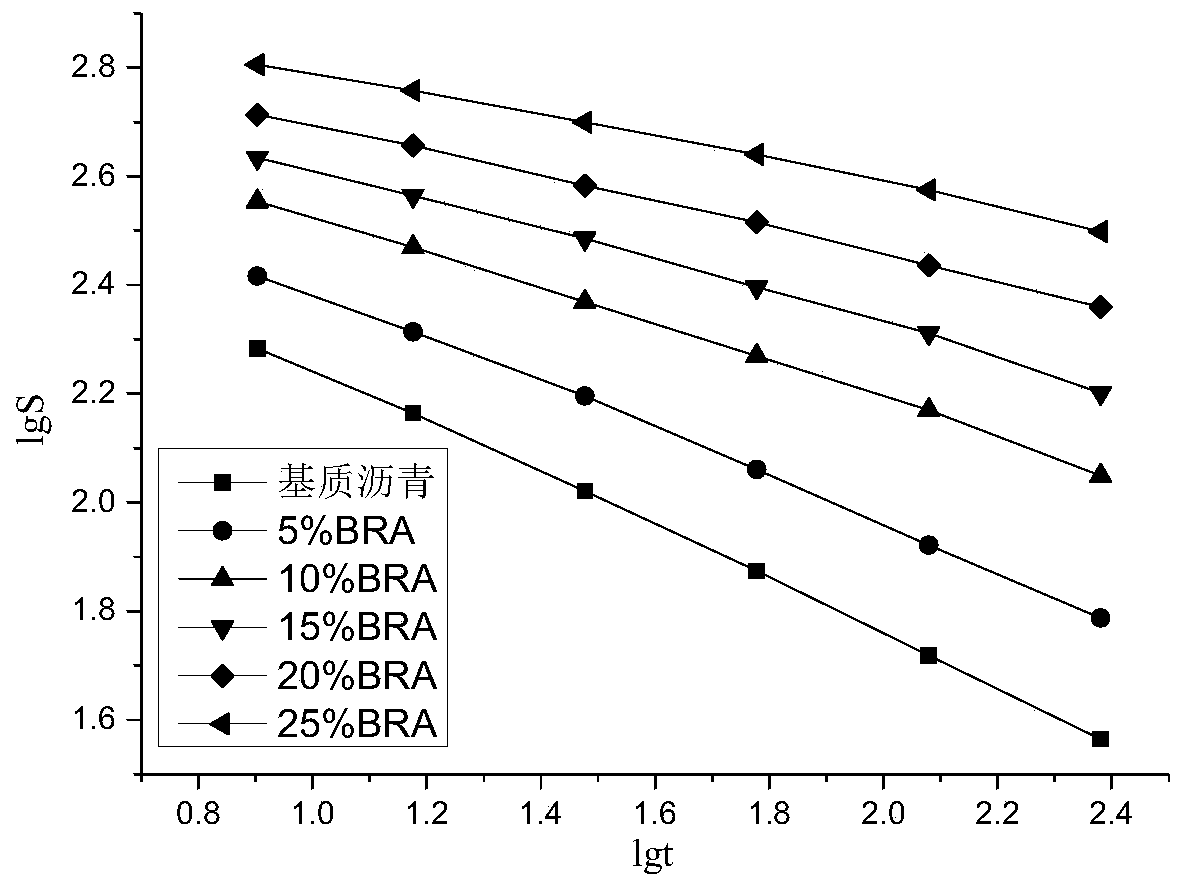

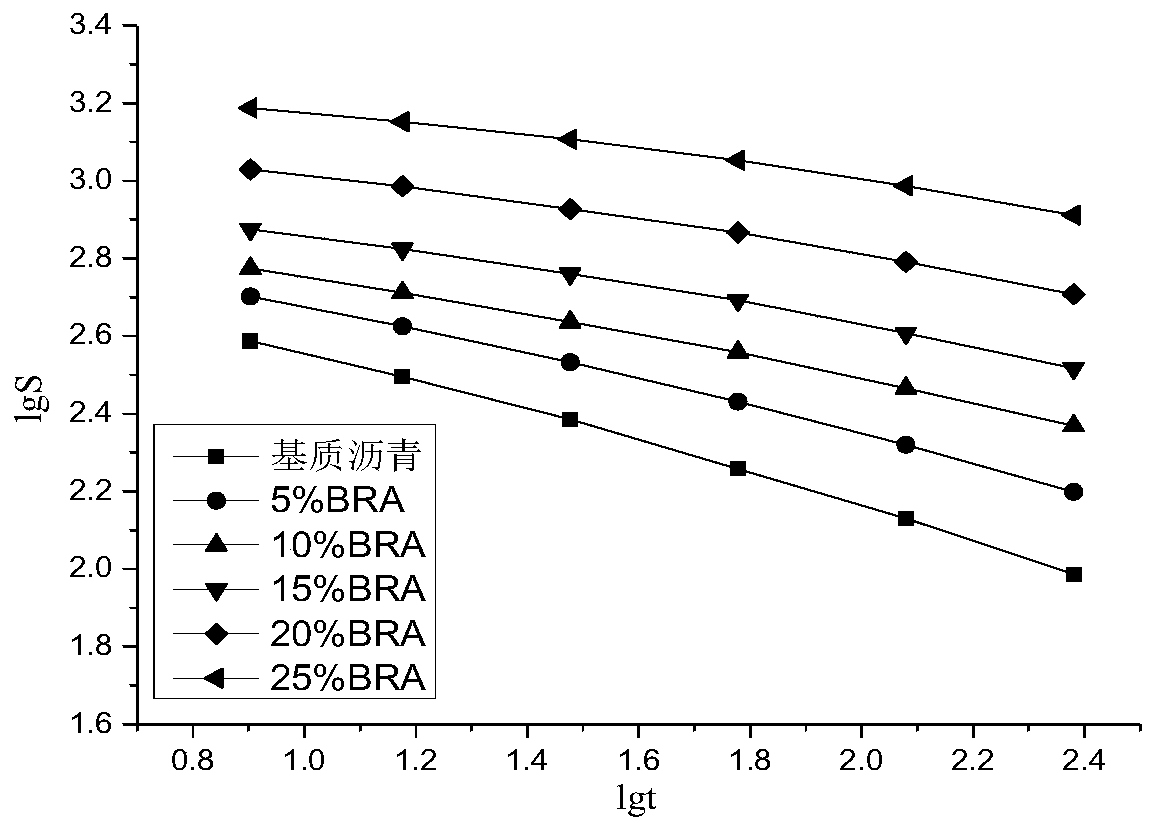

[0109] Depend on figure 2 From the results in , it can be clearly known that the 10°C ductility of BRA modified asphalt decreases gradually with the increase of BRA content. After adding 5% and 10% BRA, the BRA modified asphalt has the same change law a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com