Multilayer sensor

A sensor and sensor module technology, applied in the field of sensors, can solve the problems of troublesome installation process, messy wiring, high cost, etc., and achieve the effect of convenient cleaning, good field of view, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

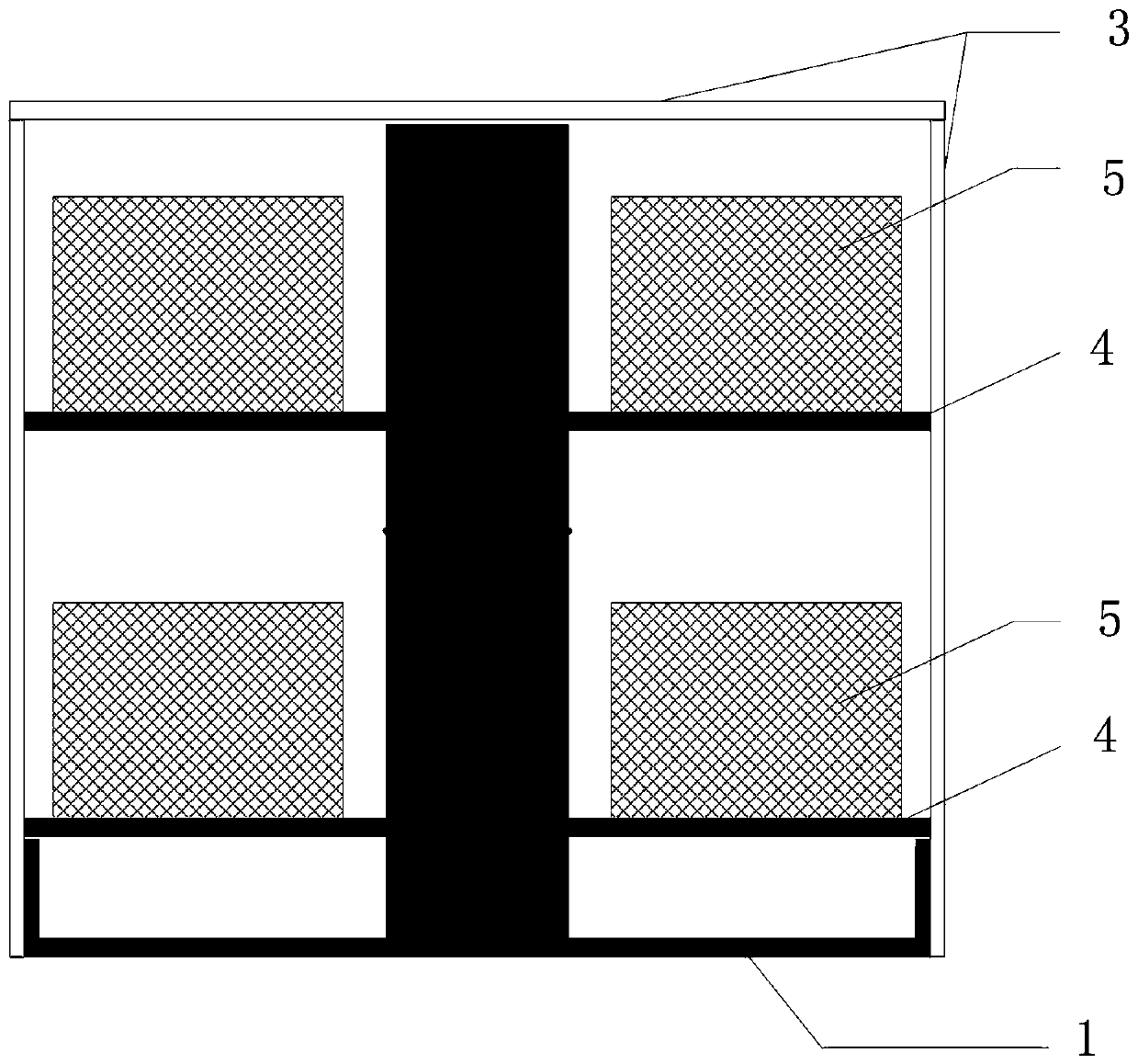

[0028] Embodiment one: if figure 1 As shown, the multi-layer sensor of this embodiment includes an equipment cabin, the equipment cabin has a complete shield 3, and inside the equipment cabin, there are at least two equipment installation platforms 4 arranged in layers in the vertical direction; Each equipment installation platform 4 is provided with at least one sensor module installation position; the outer surface of the shield 3 is integrally formed. The outer surface of the shield 3 has a single curvature. A cleaning device 6 is installed outside the shield 3 for cleaning the shield 3 .

[0029] In this embodiment, the equipment compartment consists of a base 1 and a shield 3 installed on the base 1 . Such as figure 1 Among them, in the equipment compartment composed of the base 1 and the shield 3, two equipment installation platforms 4 spliced up and down are set up, and each equipment installation platform 4 has two sensor module installation positions, and the sen...

Embodiment 2

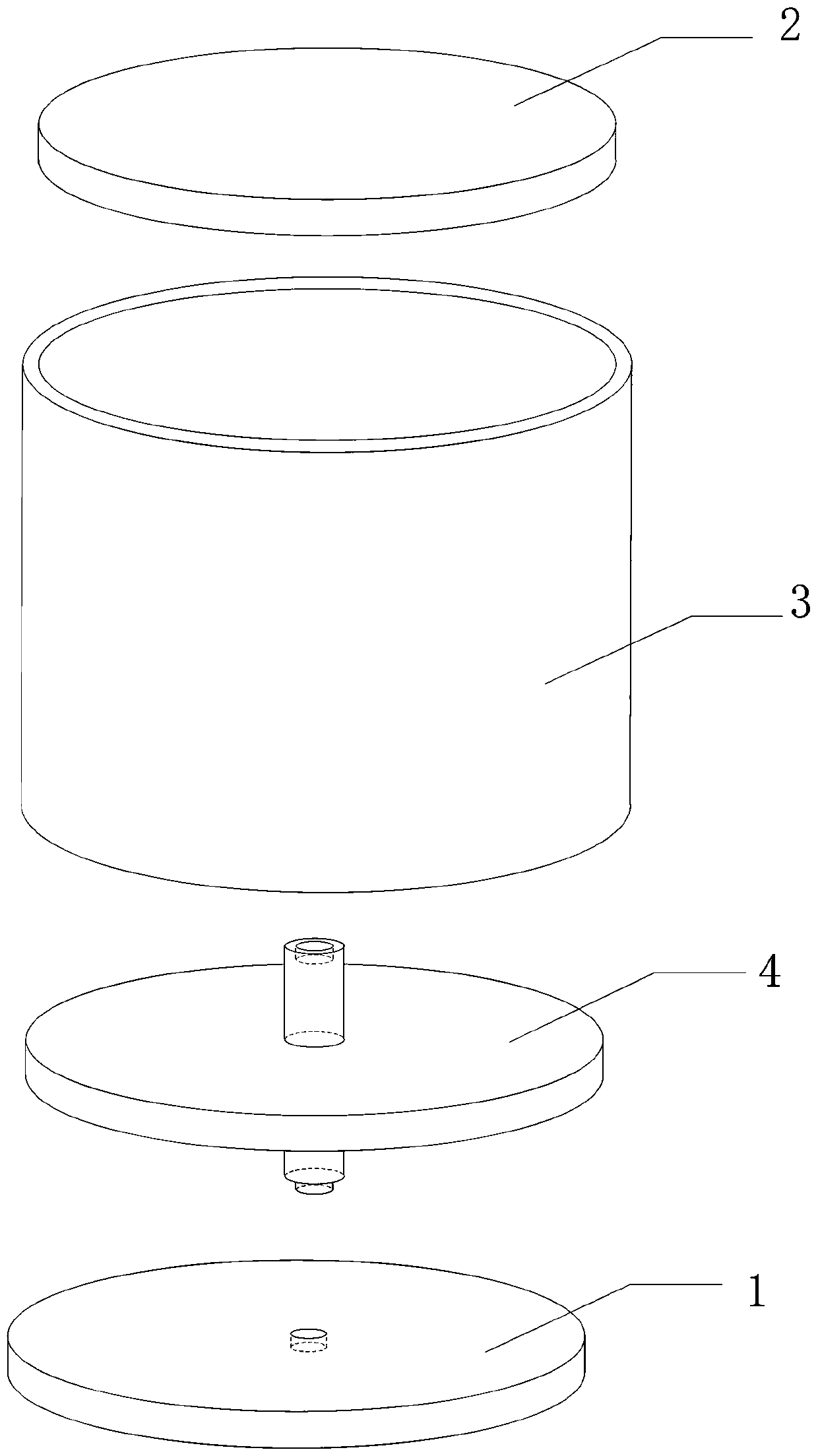

[0035] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that. Such as figure 2 As shown, the equipment compartment is composed of a base 1 , a shield 3 and an upper cover 2 , and the upper cover 2 is arranged above the shield 3 . Since the upper cover 2 and the shield 3 are split, the sensor can be installed more conveniently.

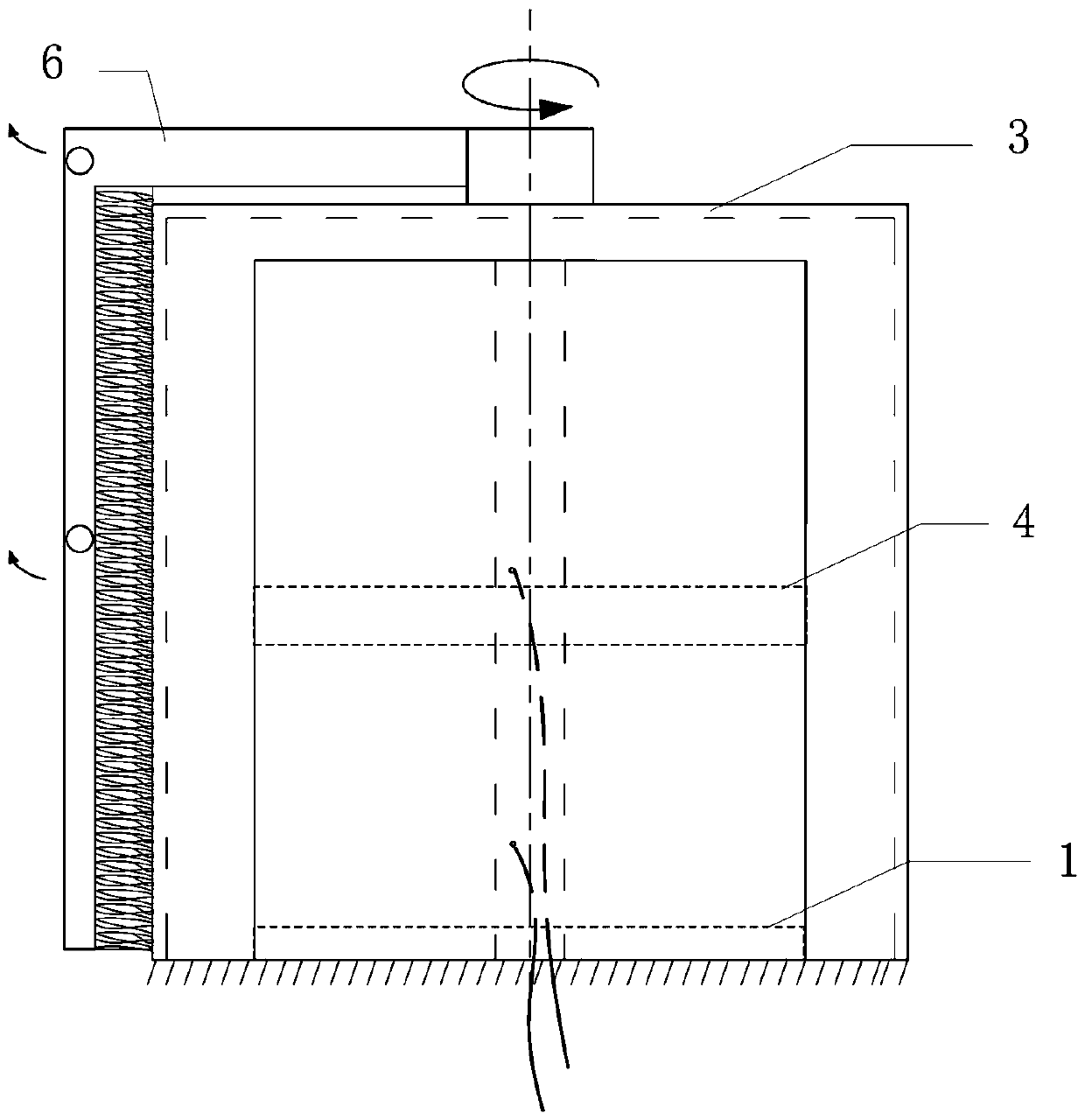

[0036] In this embodiment, the shield 3 is a rotating shield 3, and the shield 3 is driven to rotate by a driving mechanism. The cleaning device 6 is a fixed cleaning device 6, which cooperates with the rotary shield 3 to form a sweeping cleaning. Such as Figure 4 As shown, the shield 3 can rotate on a horizontal plane, the cleaning device 6 is fixed on the outer surface of the shield 3, the cleaning device 6 is provided with a cleaning part, the cleaning part is in contact with the outer surface of the shield 3, and through the rotation of the shield 3, To realize the cleaning of the outer surface of the entire shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com