Heat supplying system of fuel gas-steam combined circulation heat power plant

A heating system and combined cycle technology, which is applied in the direction of steam central heating system, heating system, household heating, etc., can solve problems such as mismatch of heat and electric load, and can meet changes, flexibly switch, and realize thermal electrolysis. coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

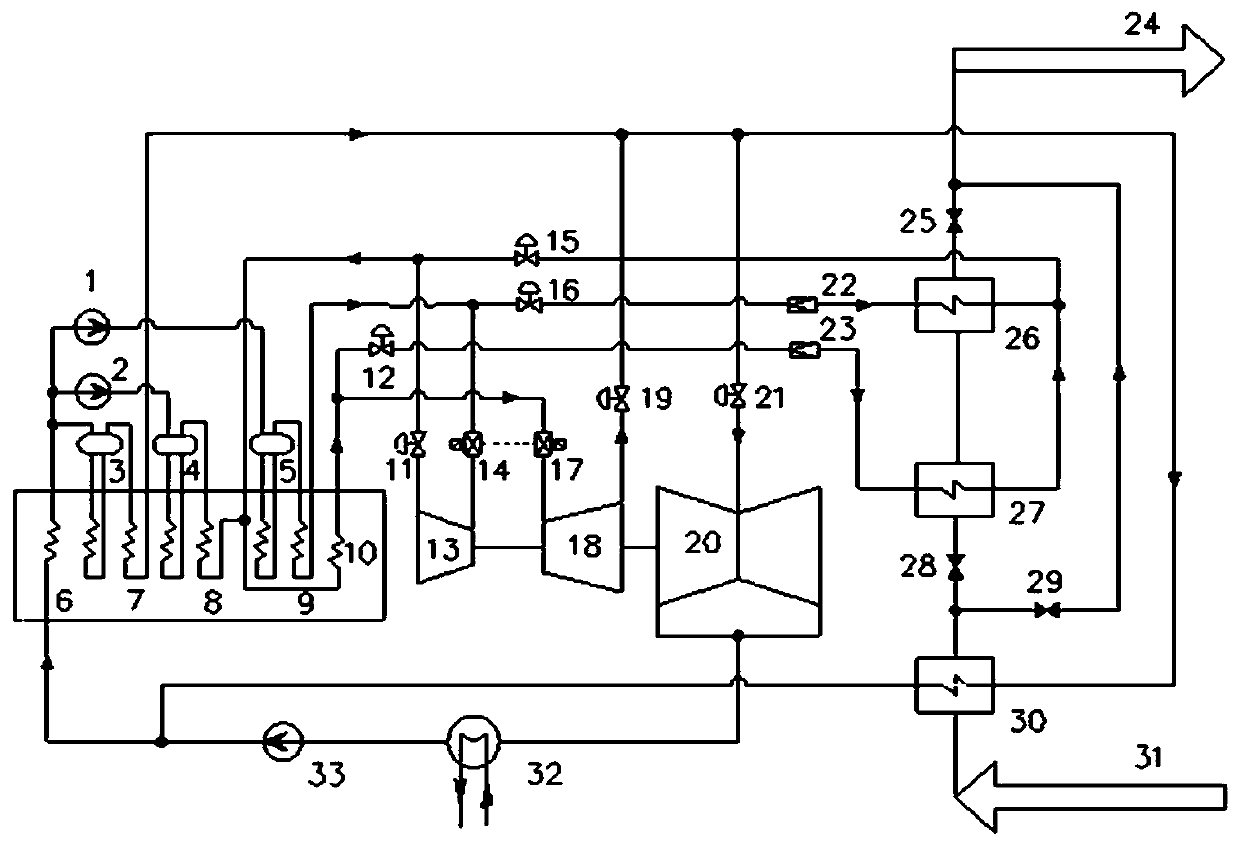

[0019] Such as figure 1 Shown, the specific embodiment of the present invention is as follows:

[0020]The invention includes a high-pressure feed water pump 1, a medium-pressure feed water pump 2, a low-pressure steam drum 3, a medium-pressure steam drum 4, a high-pressure steam drum 5, a low-pressure economizer 6, a low-pressure superheater 7, a medium-pressure superheater 8, and a high-pressure superheater 9. Reheater 10, first steam flow regulating valve 11, second steam flow regulating valve 12, high pressure cylinder 13, first electromagnetic regulating valve 14, third steam flow regulating valve 15, fourth steam flow regulating valve 16, The second electromagnetic regulating valve 17, the medium pressure cylinder 18, the fifth steam flow regulating valve 19, the low pressure cylinder 20, the sixth steam flow regulating valve 21, the high pressure bypass reducing valve 22, the medium pressure bypass reducing valve 23, the fifth A shut-off valve 25, a first heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com