Hot forming process and mould for crossed reinforcing bars of inside and outside surfaces of thin-walled barrel-type part

A technology of inner and outer surfaces and thin-walled tubes, which is applied in metal rolling and other directions, can solve problems such as the difficulty in ensuring the repeatability of longitudinal ribs in cylindrical structural parts, the difficulty in predicting the three-way flow of metal, and the difficulty in forming cross ribs, etc., to achieve debugging The process is convenient, the problem of geometric defects is solved, and the cost of manufacturing and maintenance is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

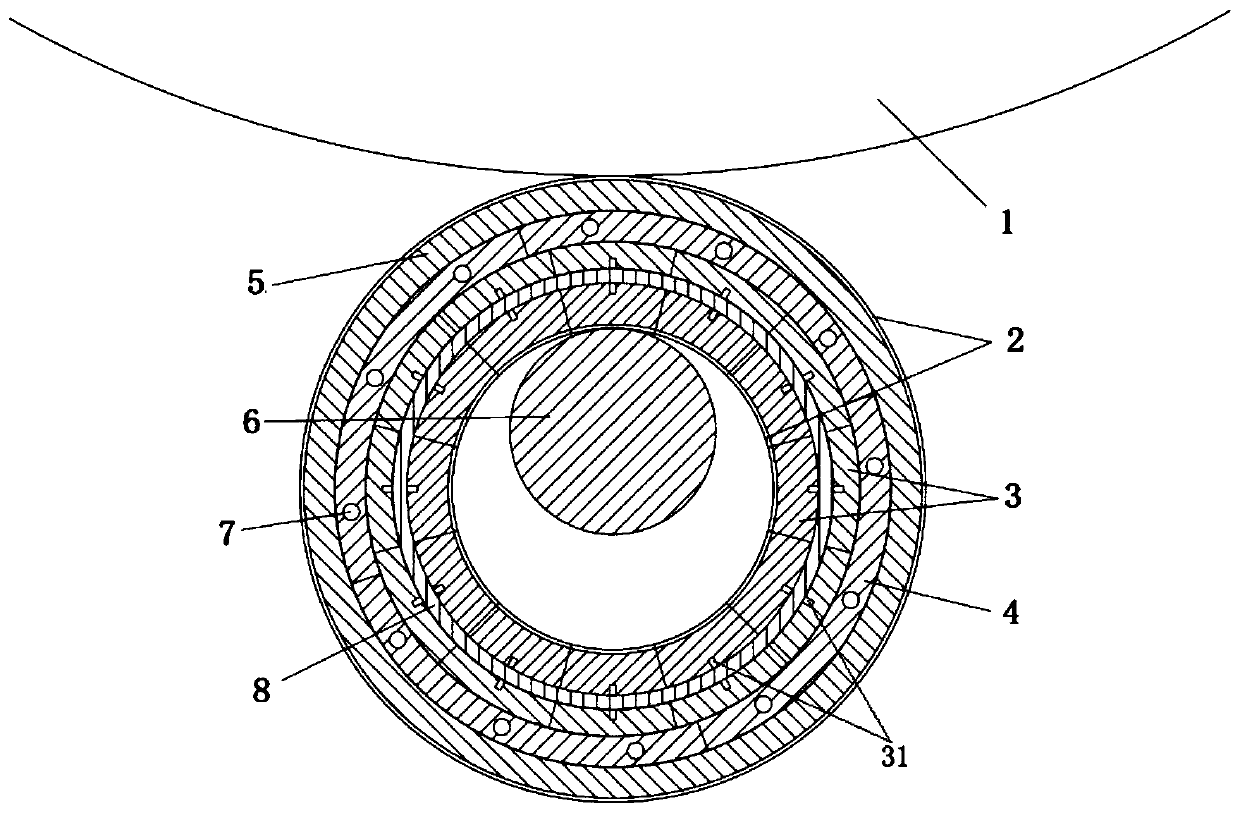

[0038] Such as figure 1 As shown, it is the first forming process of the present invention. The main structure shown in the figure is a radial rotary extrusion die. The die is mainly divided into four parts. The inner mold 4 is embedded in the outer mold 5, and the two are assembled in an L-shaped manner; the split inner mold 4 is composed of a base and four split molds, and this structure can ensure convenient demoulding after the test; the heating resistors 7 are evenly distributed in the split Around the inner mold, 12 heating resistors are distributed at intervals of 30 degrees on the circumference, and each heating resistor corresponds to a pair of sheet molds 3 with cross ribs; the cylindrical structural member 8 is installed in the middle of the sheet mold 3, and The diameter is the same as the inner diameter of the sheet mold 3, both of which are 200mm; the sheet mold 3 is composed of an inner and outer sheet mold, and the outer wall of the inner sheet mold has any cro...

Embodiment 2

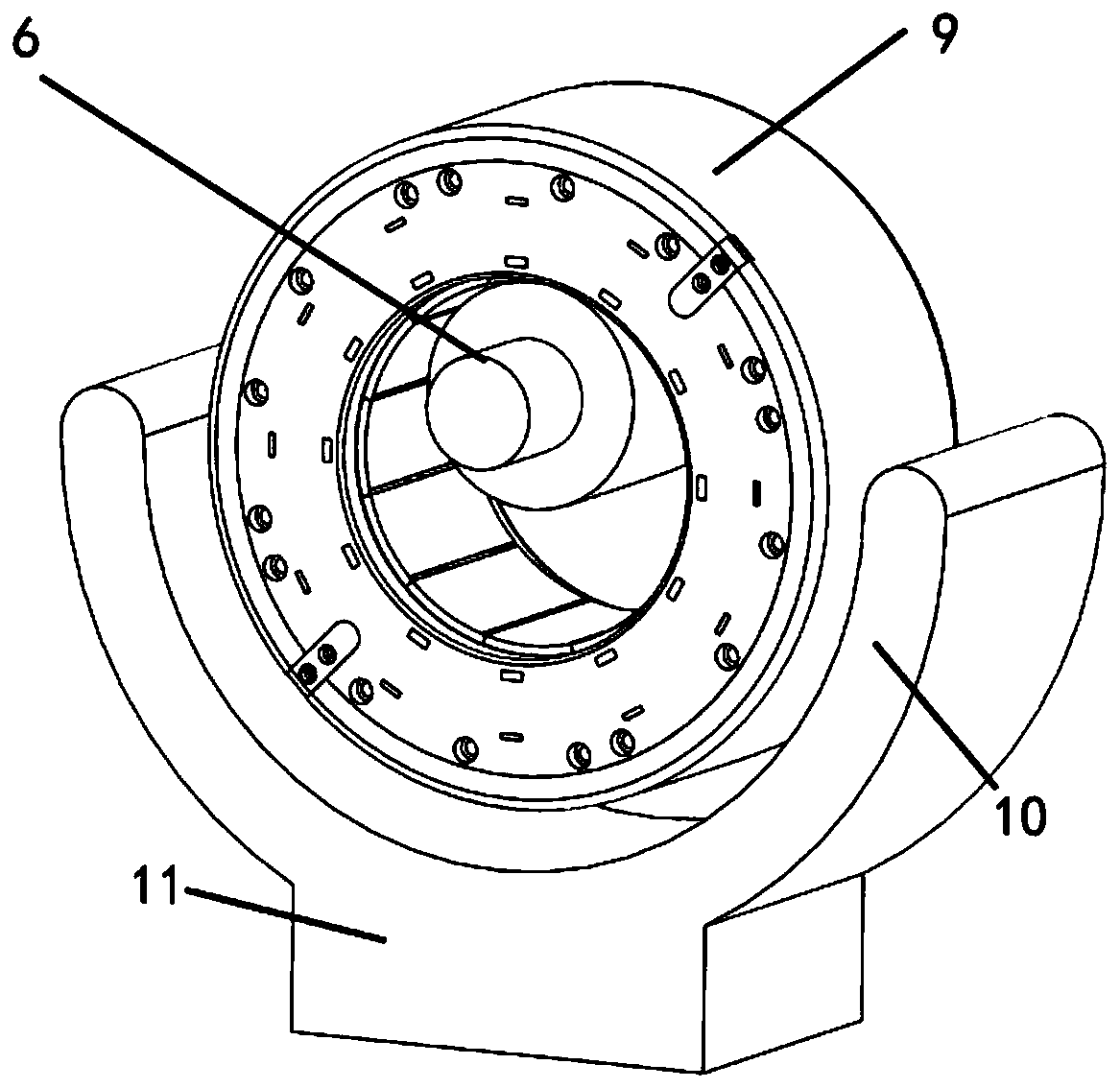

[0043] Such as figure 2As shown, it is the second forming process of the present invention. The main structure shown in the figure is a radial rotary extrusion die 9, a half-open induction heater 10, and a PID constant temperature control box 11. Among them, the biggest difference between the radial rotary extrusion die 9 and the first process is that there is no need to use a built-in heating resistor, and the internal part body mold 4 cancels the prefabricated hole of the heating resistor, and its structure also adopts a combination of a base and four split molds. This structure It can ensure the convenience of demoulding after the test; the outermost part is the integral outer mold 5, which is also the main load-bearing component; the split inner mold 4 is embedded inside the outer mold 5, and the two are assembled in an L-shaped manner; the cylindrical structural part 8 is installed In the middle of the sheet mold 3, its outer diameter is the same as the inner diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com