Road milling machine

A milling machine and ground technology, applied in the field of ground milling machines, can solve the problems of cumbersome transfer and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

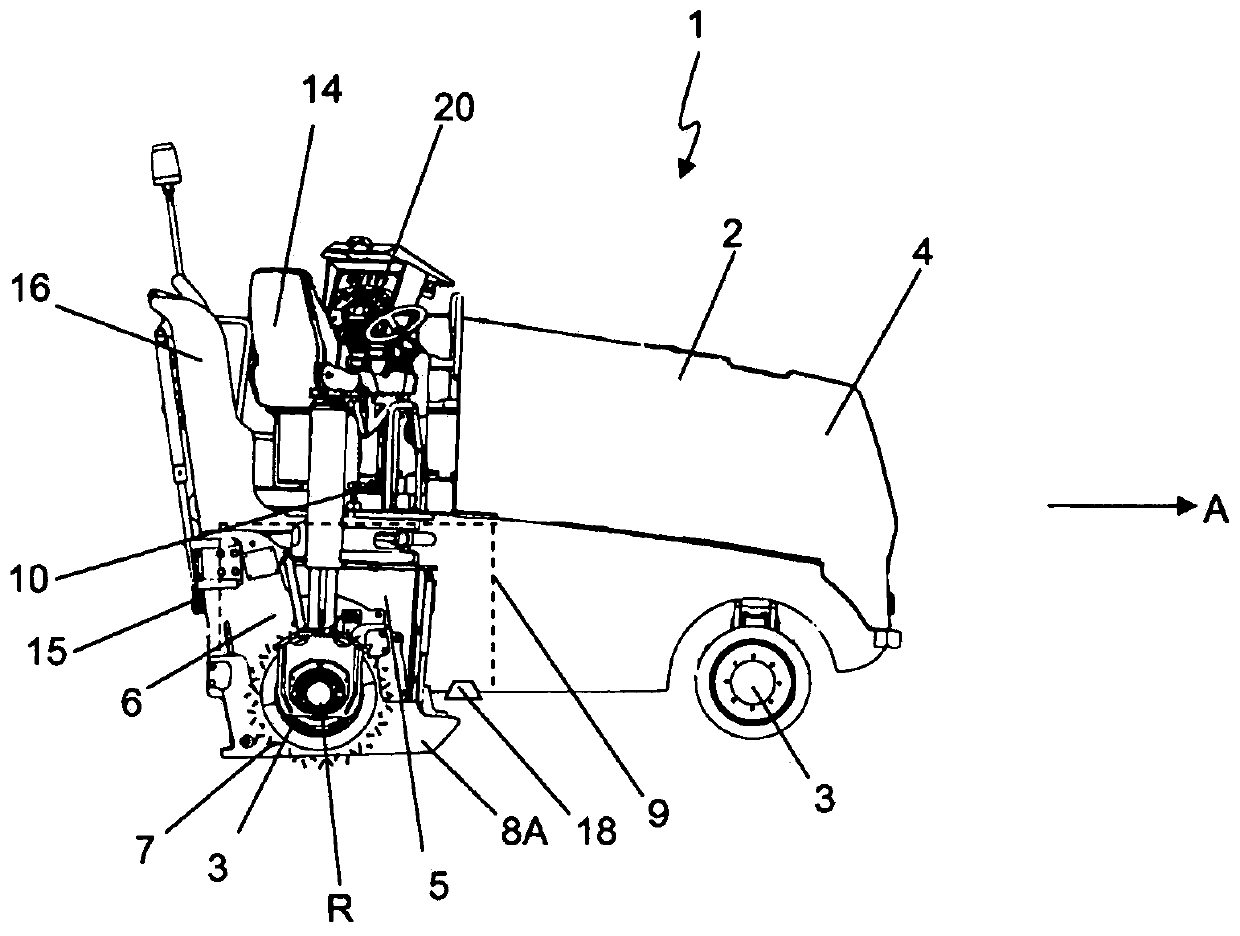

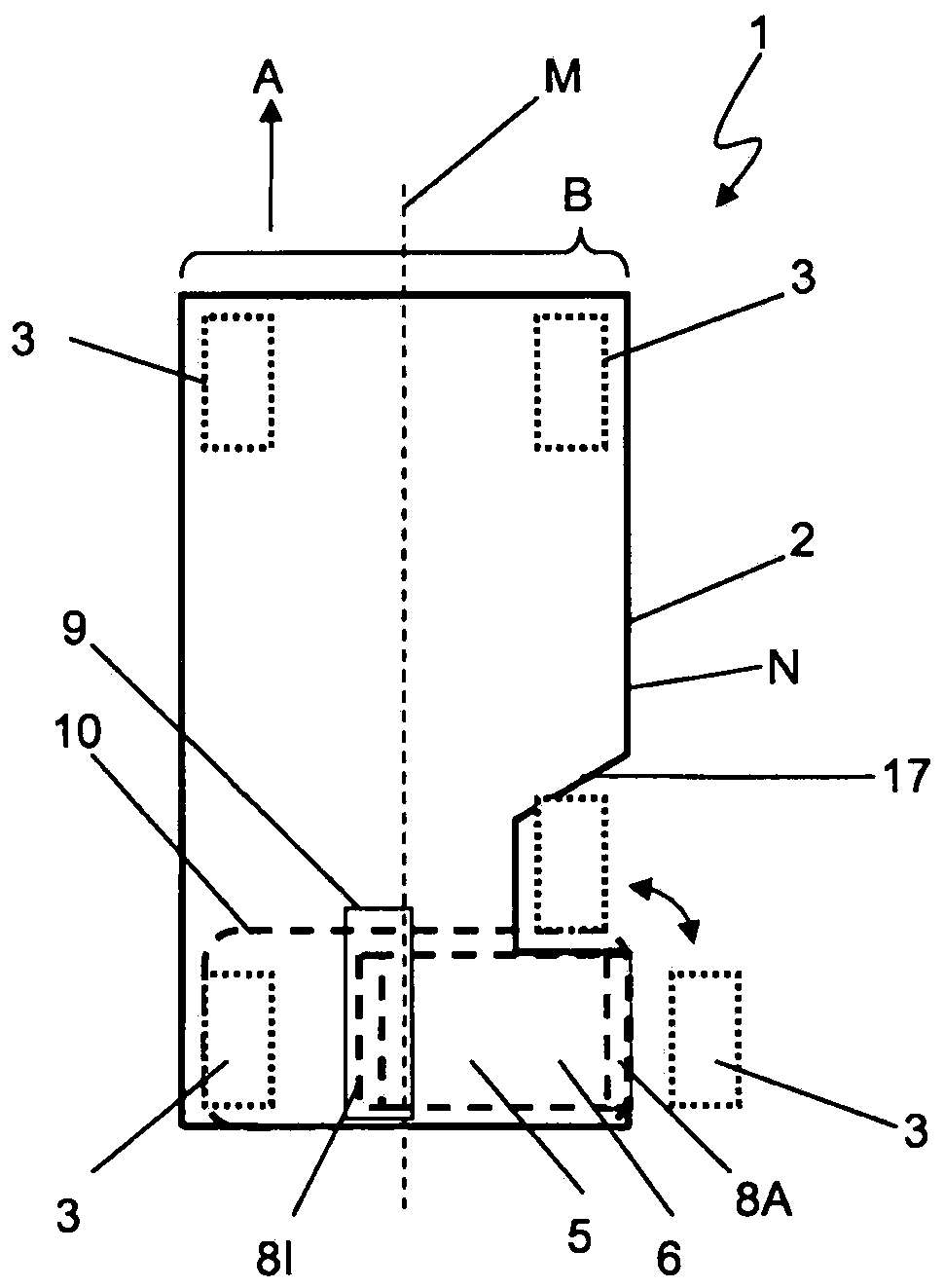

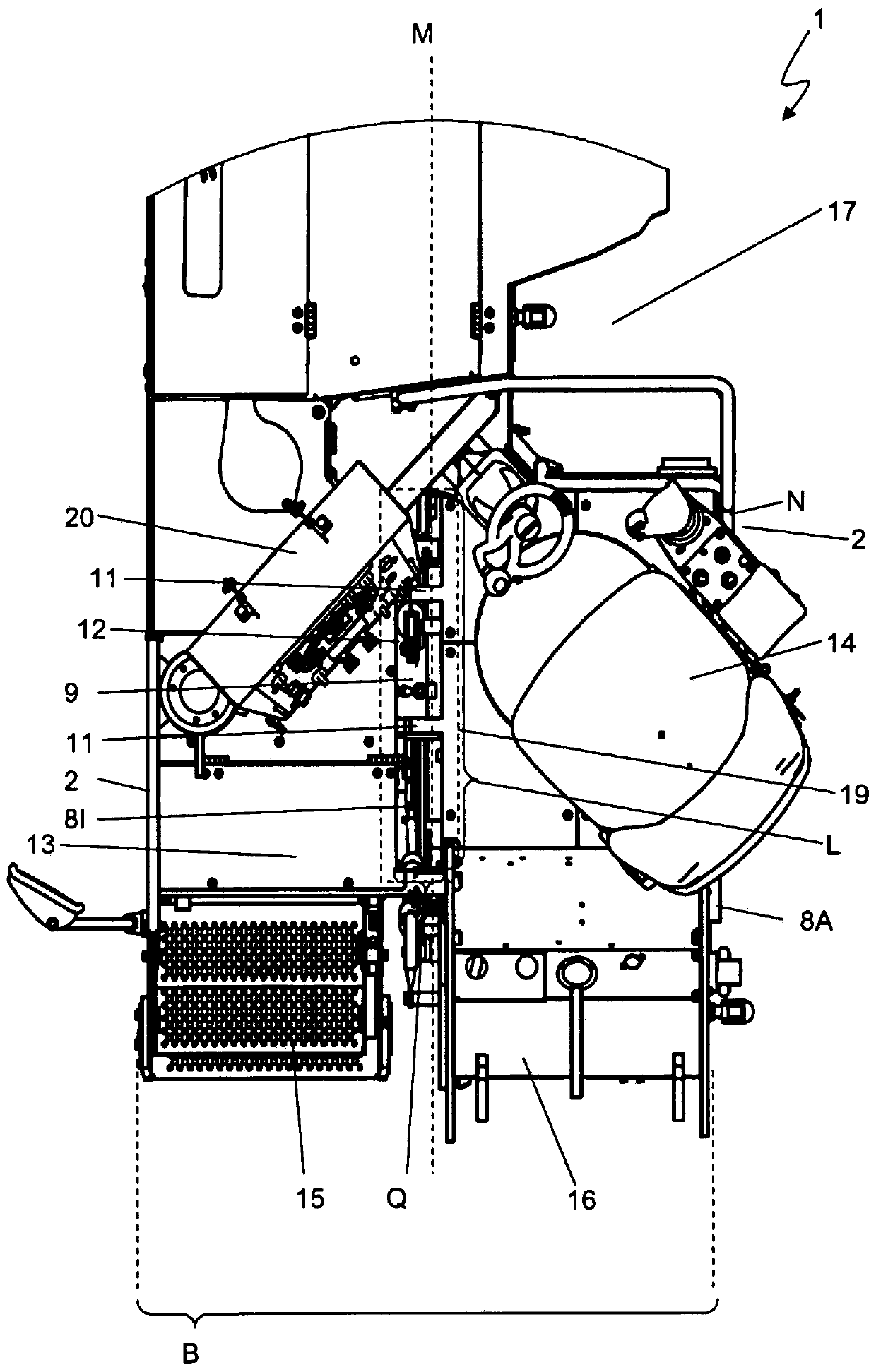

[0029] by Figure 1A The main elements of a ground milling machine 1 of the described type can be seen in the side view. In addition to the frame 2 , the ground milling machine 1 also includes: a traveling device 3 , such as a crawler mechanism or wheels; a drive motor 4 , specifically a diesel engine; a ground milling device 5 ; and a driving platform 10 . The traveling device 3 is connected to the frame 2, for example via lifting columns, so that the frame 2 is height-adjustable relative to the foundation. The drive energy required for the operation of the ground milling machine is provided by the drive motor 4 . During working mode, the ground milling machine 1 is operated by an operator on the operator's platform 10 . The ground milling machine 1 shown is in particular a so-called tail rotor milling machine, wherein the ground milling device 5 is arranged in the rear region of the ground milling machine 1 below the operator's cab 10 .

[0030] The ground is milled by mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com